Autoclave liquid phase reduction preparation method for shape-controllable CO2FeAl nanometer structure

A nanostructure and autoclave technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve problems such as difficult to put into actual production, complex sample preparation process, high equipment requirements, etc., to achieve good soft magnetic properties, process Simple, low-equipment-required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

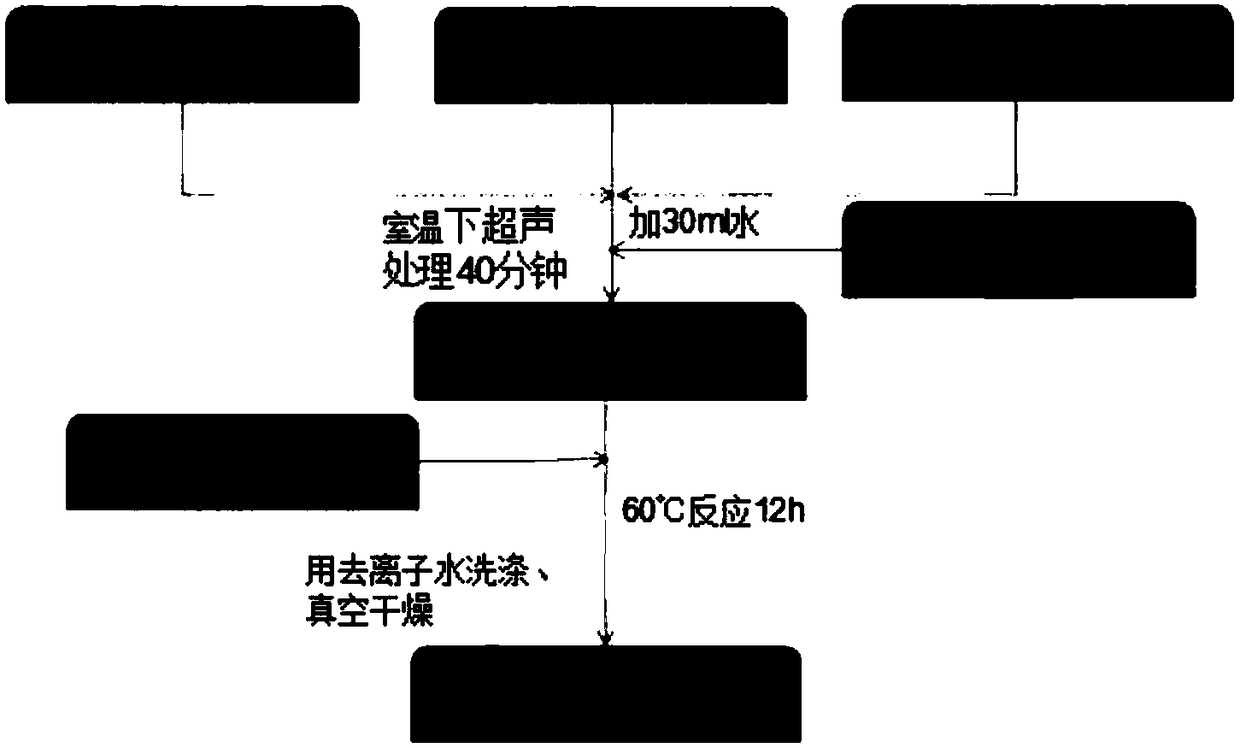

[0017] Such as image 3 Shown, specific embodiment of the present invention is as follows:

[0018] All chemical reagents were of analytical grade. In this experiment, 1.78 g CoCl2 6H2O, 0.75 g FeCl2 4H2O and 0.9 g AlCl3 6H2O were dissolved in 30 ml deionized water and magnetically stirred for 10 minutes. An appropriate amount of NaOH pellets was then added, the resulting mixture was stirred vigorously for 15 minutes, and 10 ml of 85% hydrazine hydrate (H4N2·H2O) reducing agent was added to the solution. The mixture was stirred for another 10 minutes, then transferred to a stainless steel autoclave with a Teflon liner. The temperature of the autoclave was maintained at 60° C. for 12 hours, and then naturally cooled to room temperature. Separate with a permanent magnet and rinse more than 5 times with deionized water. The final product was dried at 50°C for 10 hours.

[0019] Figure 4 For Co reacted for 12h under different reaction temperatures 2 The XRD pattern of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com