Monitoring method for single-phase intelligent electric energy meter automatic verification production line

A smart electric energy meter and verification assembly line technology, applied to measuring devices, measuring electrical variables, instruments, etc., can solve problems such as assembly line instrument failures, low work efficiency, and random abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

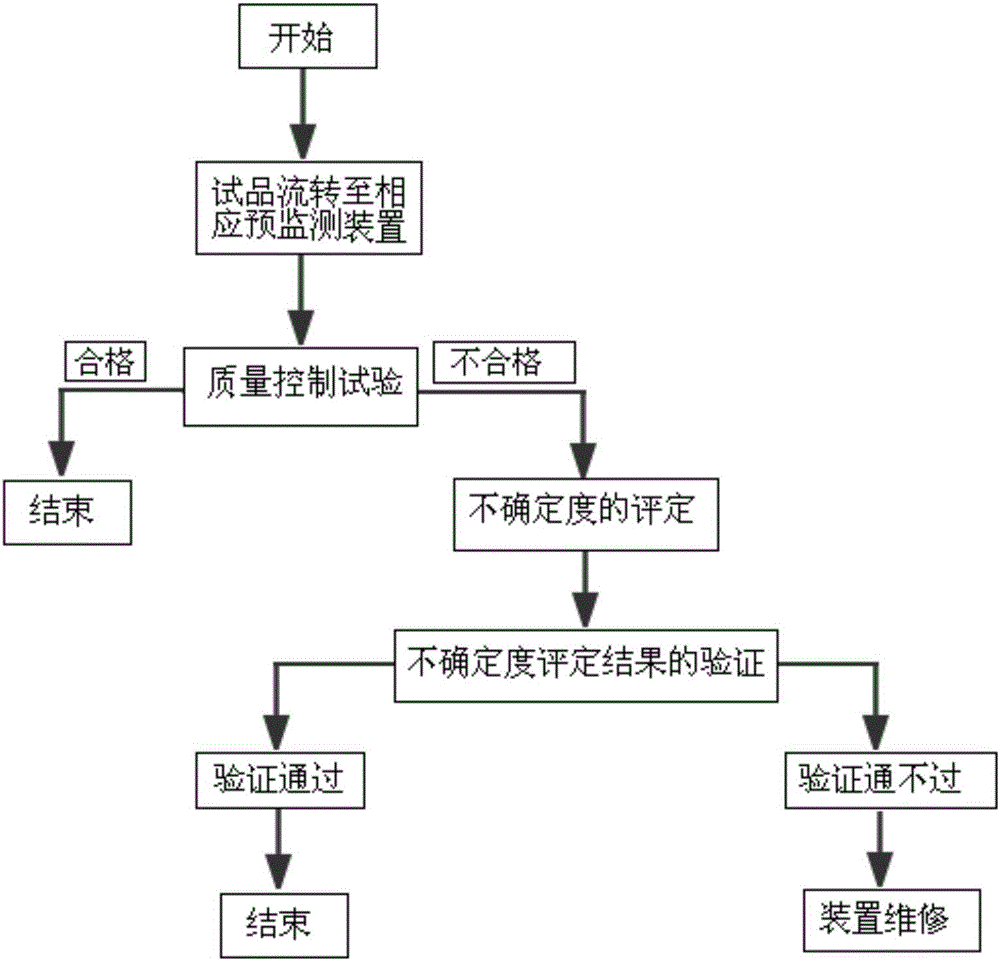

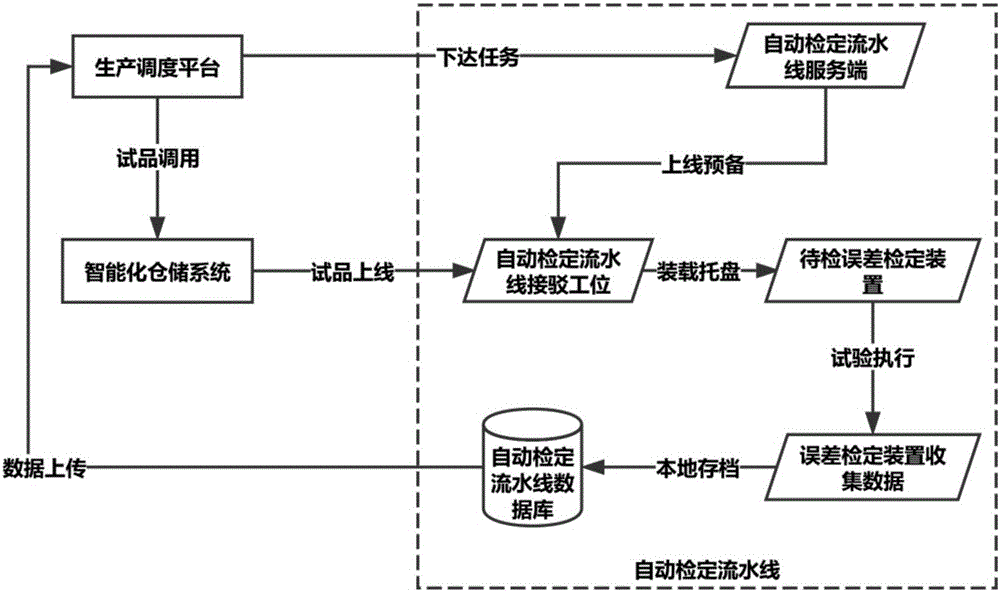

[0083] As shown in the figure, one, the main system composition involved in the present invention

[0084] 1. The main system designed by the present invention includes a production scheduling platform, a single-phase intelligent electric energy meter automatic verification assembly line, and an intelligent three-dimensional storage system. Among them, the production scheduling platform is the management platform of the verification assembly line and the storage system, responsible for verification tasks and program management, warehouse management, data management and other work tasks. Management and calculation of test data;

[0085] 2. The automatic verification assembly line of single-phase smart energy meters is seamlessly connected with the platform and the storage system through physical connection and communication network, which can realize online transmission, test wiring, test execution, and automatic verification of single-phase smart energy meters. Operations suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com