A kind of elliptical polarization maintaining optical fiber and its preparation method

A polarization-maintaining optical fiber and optical fiber preform technology, which can be applied to polarization optical fibers, cladding optical fibers, glass manufacturing equipment, etc., can solve the problems of low birefringence optical fibers being sensitive to interference, expensive, and difficult to prepare circular polarization-maintaining fibers. High Faraday effect, improved paramagnetism, and the effect of using slender

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

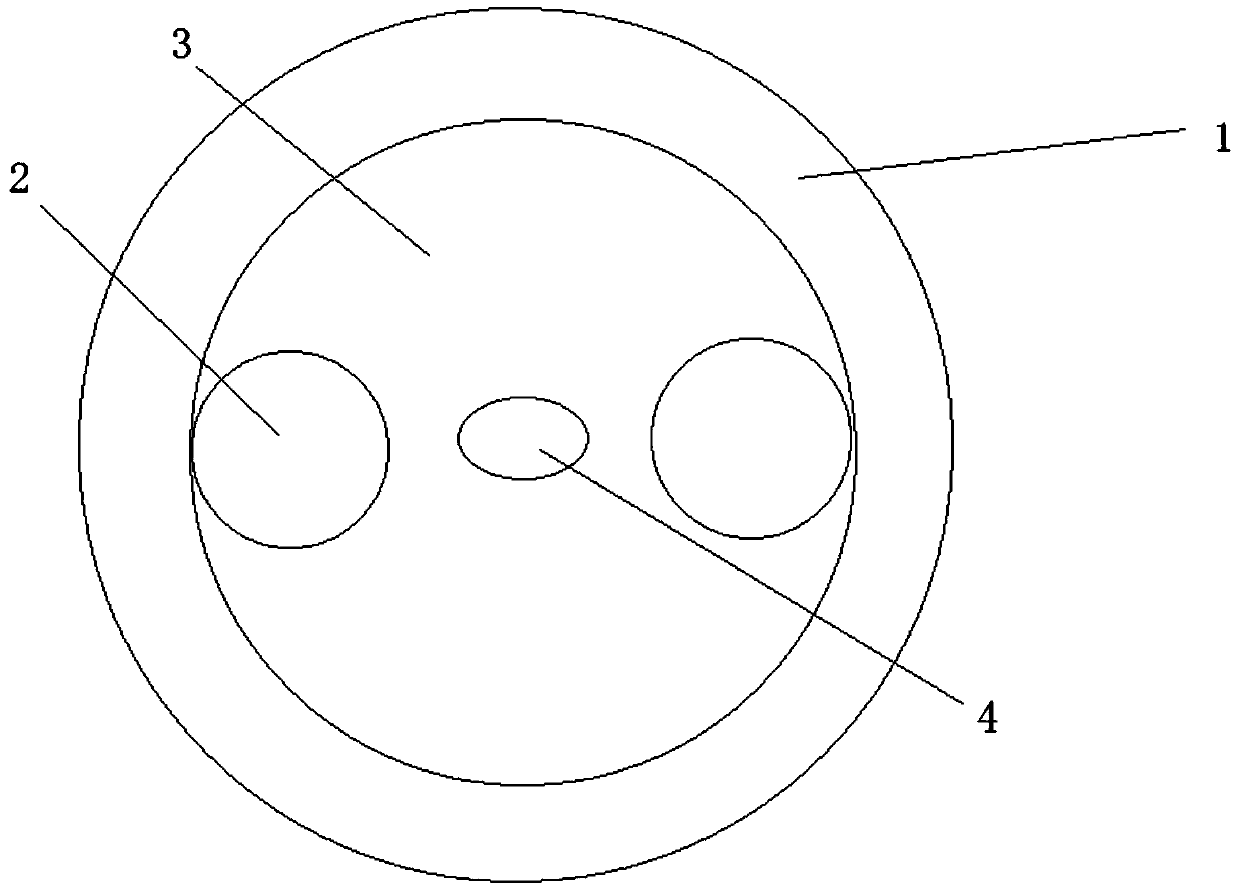

[0033] A kind of elliptical polarization maintaining optical fiber, its structure is as figure 1 As shown, the cross-sectional structure of the polarization-maintaining optical fiber is an elliptical core layer 4 from the inside to the outside, the inner cladding layer 3 wrapping the core layer 4, and the stress action zone layer 2 wrapping the inner cladding layer 3, And the outer cladding layer 1 wrapping the stress application zone layer 2, the core layer 4 is also doped with 800ppm Tb 2 o 3 and 250ppm CeO 2 , the roundness of the core layer 4 is 60%, and the diameter of the elliptical polarization-maintaining fiber is 120 μm, wherein, the major axis length of the core layer 4 and the inner cladding layer 3, the stress action zone layer 2 and the outer cladding layer 1 has a diameter ratio of 4:40:100:125.

[0034] The preparation method of the above-mentioned elliptical polarization maintaining optical fiber comprises the following steps:

[0035] (1) Pass SiCl into th...

Embodiment 2

[0044] An elliptical polarization-maintaining optical fiber, the cross-sectional structure of the polarization-maintaining optical fiber is an elliptical core layer 4 from the inside to the outside, the inner cladding 3 wrapping the core layer 4, and the stress effect of wrapping the inner cladding 3 zone layer 2, and the outer cladding layer 1 wrapping the stress action zone layer 2, and the core layer 4 is also doped with 1000ppm Tb 2 o 3 and 300ppm CeO 2 , the roundness of the core layer 4 is 90%, and the diameter of the elliptical polarization-maintaining fiber is 130 μm, wherein, the major axis length of the core layer 4 and the inner cladding layer 3, the stress action zone layer 2 and the outer cladding layer 1 has a diameter ratio of 4:40:100:125.

[0045] The preparation method of the above-mentioned elliptical polarization maintaining optical fiber comprises the following steps:

[0046] (1) Pass SiCl into the quartz substrate tube at a molar ratio of 1.2:1 4 and...

Embodiment 3

[0054] An elliptical polarization-maintaining optical fiber, the cross-sectional structure of the polarization-maintaining optical fiber is an elliptical core layer 4 from the inside to the outside, the inner cladding 3 wrapping the core layer 4, and the stress effect of wrapping the inner cladding 3 zone layer 2, and the outer cladding layer 1 wrapping the stress action zone layer 2, and the core layer 4 is also doped with 900ppm Tb 2 o 3 and 275ppm CeO 2 , the roundness of the core layer 4 is 75%, and the diameter of the elliptical polarization-maintaining fiber is 125 μm, wherein, the major axis length of the core layer 4 and the inner cladding layer 3, the stress action zone layer 2 and the outer cladding layer 1 has a diameter ratio of 4:40:100:125.

[0055] The preparation method of the above-mentioned elliptical polarization maintaining optical fiber comprises the following steps:

[0056] (1) Pass SiCl into the quartz substrate tube at a molar ratio of 1.1:1 4 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com