Hand-held controller and control method thereof

A controller and microcontroller technology, applied in program control, computer control, general control systems, etc., can solve the problems of inability to transmit information, difficult to ensure the accuracy of automated operations, and achieve high measurement accuracy and obvious communication effects. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

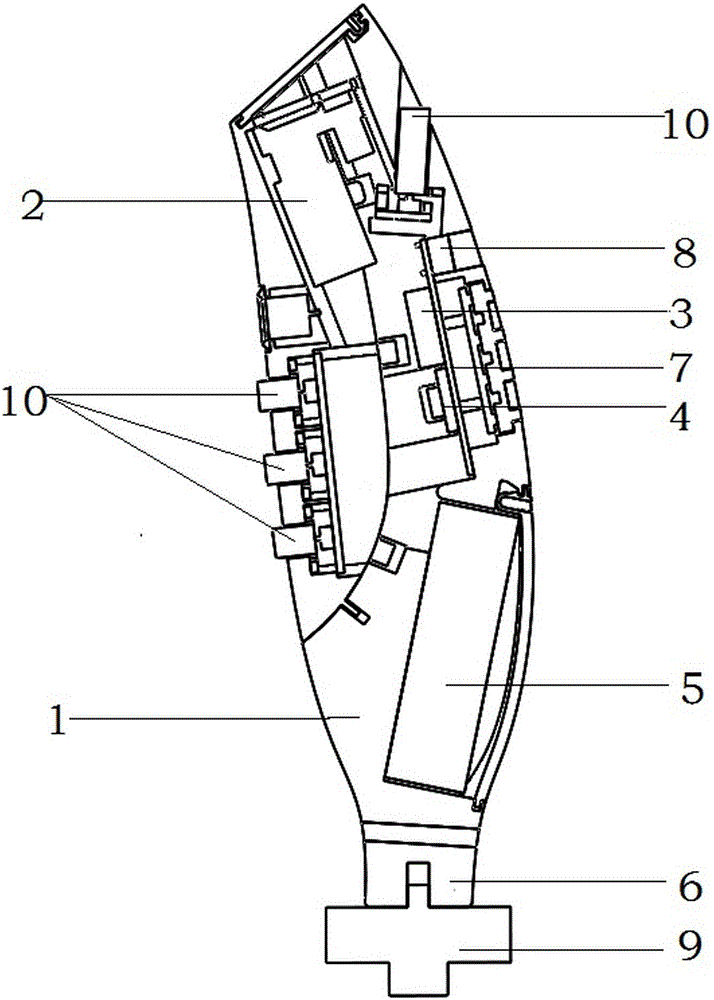

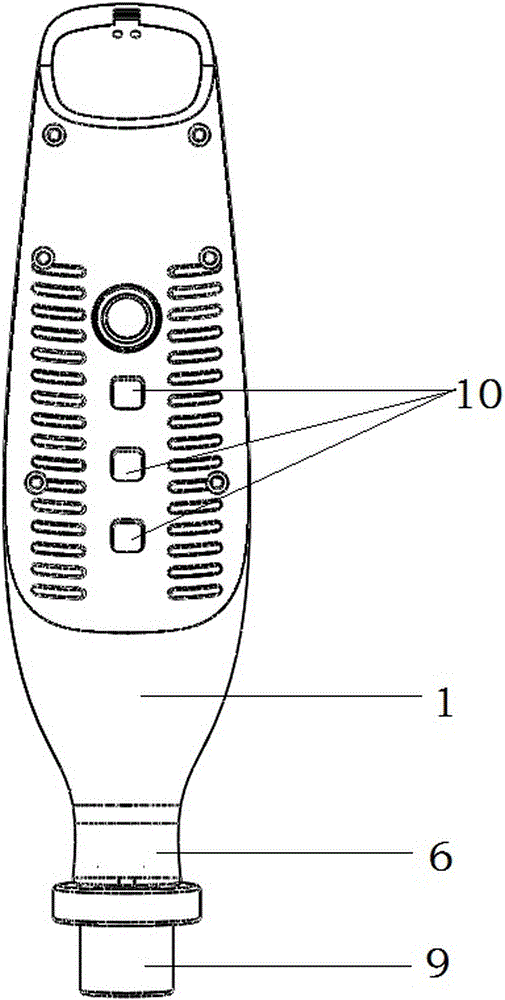

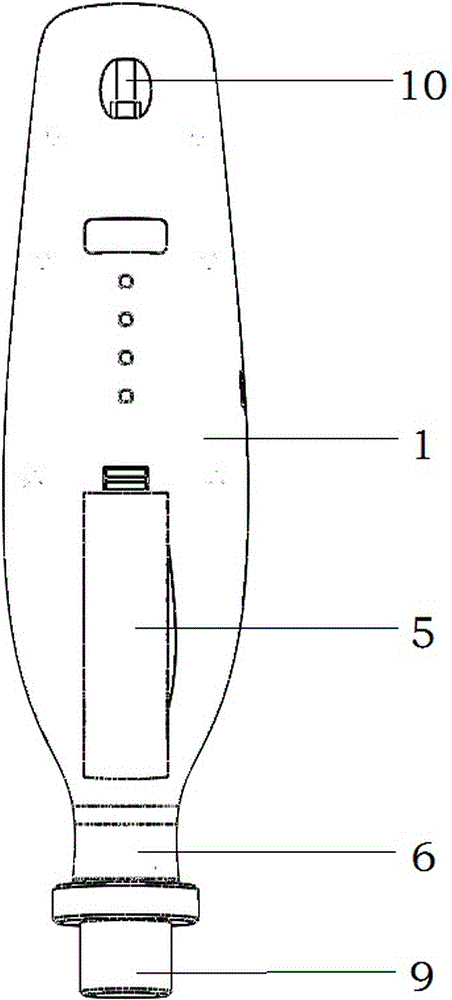

[0034] Such as Figure 1 to Figure 6, a hand-held controller, including a hand-held operator and a receiver; the hand-held operator includes a housing 1, which includes a temperature module 2, a wireless communication module 3, a battery management module 4, a battery 5 and a heat insulation pad Block 6, and the microcontroller, gyroscope and nixie tube 8 integrated on the main board 7 of the hand-held operator; the housing is provided with an adapter base 9 and a self-recovery micro-switch 10 for switching modes , the self-recovery microswitch 10 is connected to the GPIO pin of the microprocessor through a pull-up resistor link mode; the digital tube is linked to the GPIO pin of the microprocessor; the receiver includes a microcontroller, a wireless communication module , Wired isolated communication module and power module.

[0035] This is one of the most basic embodiments of the present invention. The temperature module 2 can measure the temperature of the workpiece in r...

Embodiment 2

[0037] Such as Figure 1 to Figure 6 , a hand-held controller, including a hand-held operator and a receiver; the hand-held operator includes a housing 1, which includes a temperature module 2, a wireless communication module 3, a battery management module 4, a battery 5 and a heat insulation pad Block 6, and the microcontroller, gyroscope and nixie tube 8 integrated on the main board 7 of the hand-held operator; the housing is provided with an adapter base 9 and a self-recovery micro-switch 10 for switching modes , the self-recovery microswitch 10 is connected to the GPIO pin of the microprocessor through a pull-up resistor link mode; the digital tube is linked to the GPIO pin of the microprocessor; the receiver includes a microcontroller, a wireless communication module , Wired isolated communication module and power module.

[0038] The self-recovery micro switch 10 includes a forward / reverse button, an automatic adjustment button and a temperature measurement button respe...

Embodiment 3

[0041] Such as Figure 1 to Figure 6 , a hand-held controller, including a hand-held operator and a receiver; the hand-held operator includes a housing 1, which includes a temperature module 2, a wireless communication module 3, a battery management module 4, a battery 5 and a heat insulation pad Block 6, and the microcontroller, gyroscope and nixie tube 8 integrated on the main board 7 of the hand-held operator; the housing is provided with an adapter base 9 and a self-recovery micro-switch 10 for switching modes , the self-recovery microswitch 10 is connected to the GPIO pin of the microprocessor through a pull-up resistor link mode; the digital tube is linked to the GPIO pin of the microprocessor; the receiver includes a microcontroller, a wireless communication module , Wired isolated communication module and power module.

[0042] The self-recovery micro switch 10 includes a forward / reverse button, an automatic adjustment button and a temperature measurement button respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com