Electrical isolator packaging structure and manufacturing method for electrical isolator

A manufacturing method and technology of an electrical isolator, which is applied in the field of signal transmission, can solve problems such as the incompatibility of light-emitting diode processes, and achieve the effects of reducing signal distortion and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

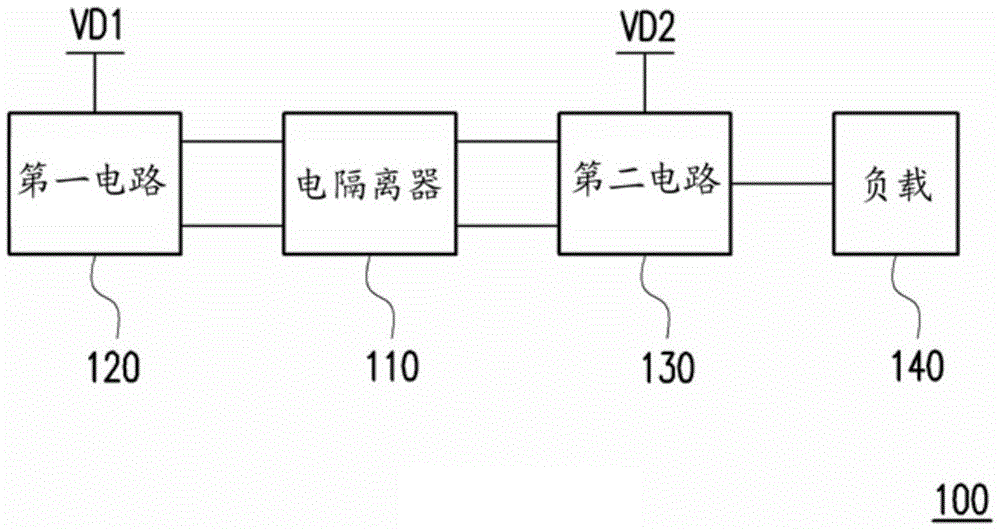

[0043] figure 1 is a schematic diagram of a circuit 100 using an electrical isolator 110 according to an embodiment of the present invention. The circuit 100 includes a galvanic isolator 110 , a first circuit 120 , a second circuit 130 and a load 140 . The power supply of the first circuit 120 is connected to the first voltage domain VD1, and the power supply of the second circuit 130 is connected to the second voltage domain VD2. The first circuit 120 may be an input stage circuit or a control circuit, and the second circuit 130 may be an output stage circuit. The load 140 is connected to the output terminal of the second circuit 130 .

[0044] In this embodiment, the first voltage domain VD1 and the second voltage domain VD2 may be different. The circuit 100 is applicable to a power circuit system, so the second voltage domain VD2 may range from 20V to 35kV, depending on the applied power circuit system. The first voltage domain VD1 is a commonly used voltage range for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com