Bottom assembly for clothes dryer and clothes dryer with such bottom assembly

A technology for clothes dryers and components, which is applied in household clothes dryers, home appliances, applications, etc., can solve problems such as limited installation space, and achieve the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

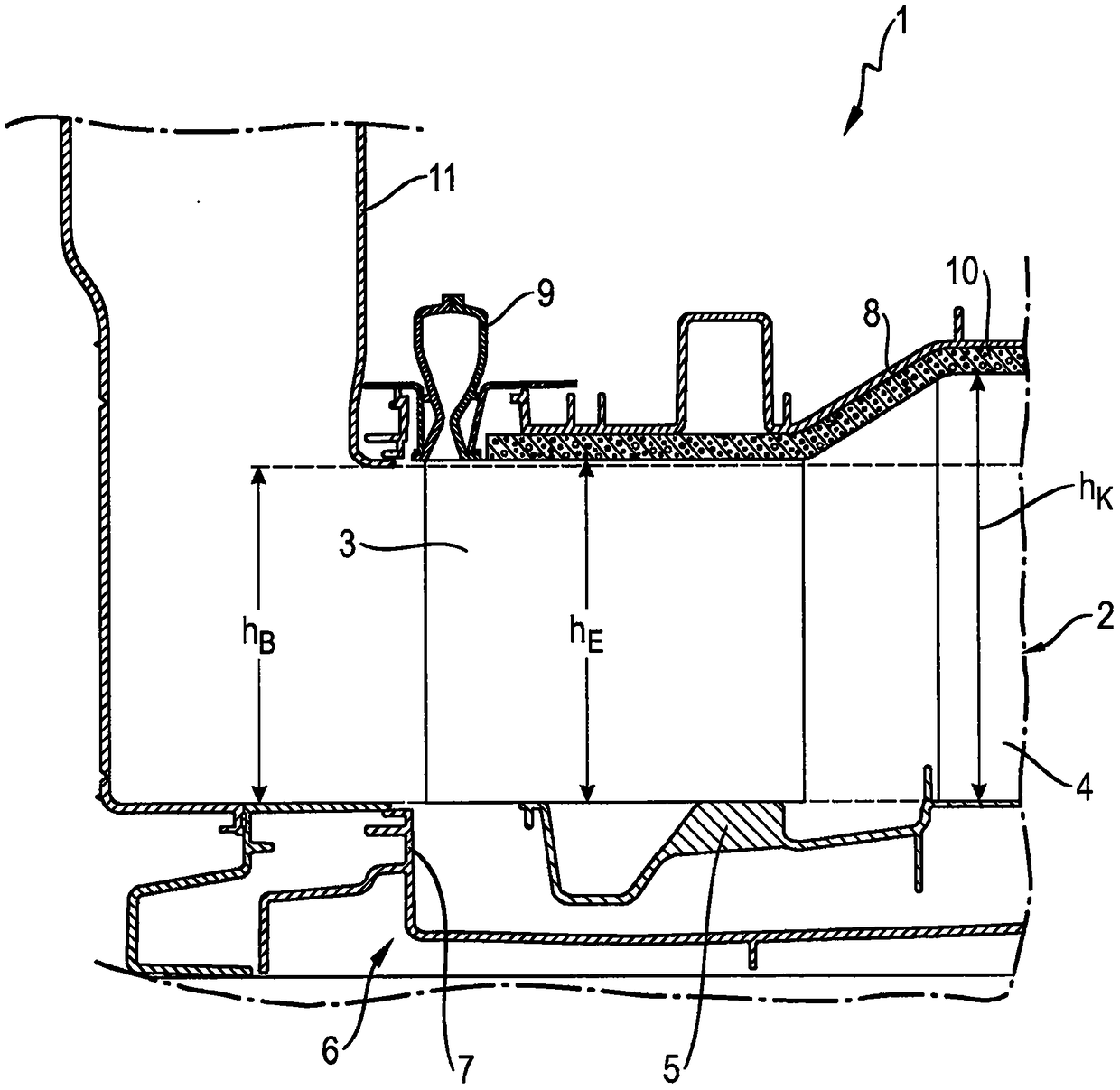

[0029] figure 1 A schematic sectional view of a conventional clothes dryer 1 with a heat pump 2 is shown. The heat pump 2 is of the type in which the circulated evaporated coolant circulates and which comprises as heat sink 3 a E The evaporator 3 and the heat source 4 with a structural height h K The condenser 4. The evaporator 3 and the condenser 4 are arranged on a partitioned bottom 5 of the bottom assembly 6 , wherein the partitioned bottom 5 is fastened to the housing 7 of the bottom assembly 6 . Cover 8 is arranged above evaporator 3 and condenser 4 with a diffuser 9 for a self-cleaning system (not shown in further detail) for cleaning evaporator 3 and / or condenser 4 , wherein cover 8 is arranged via sealing foam 10 is connected with evaporator 3 and condenser 4. with h B To indicate the height of the structural space available between the partition base 5 and the other structural element 11 of the dryer 1 .

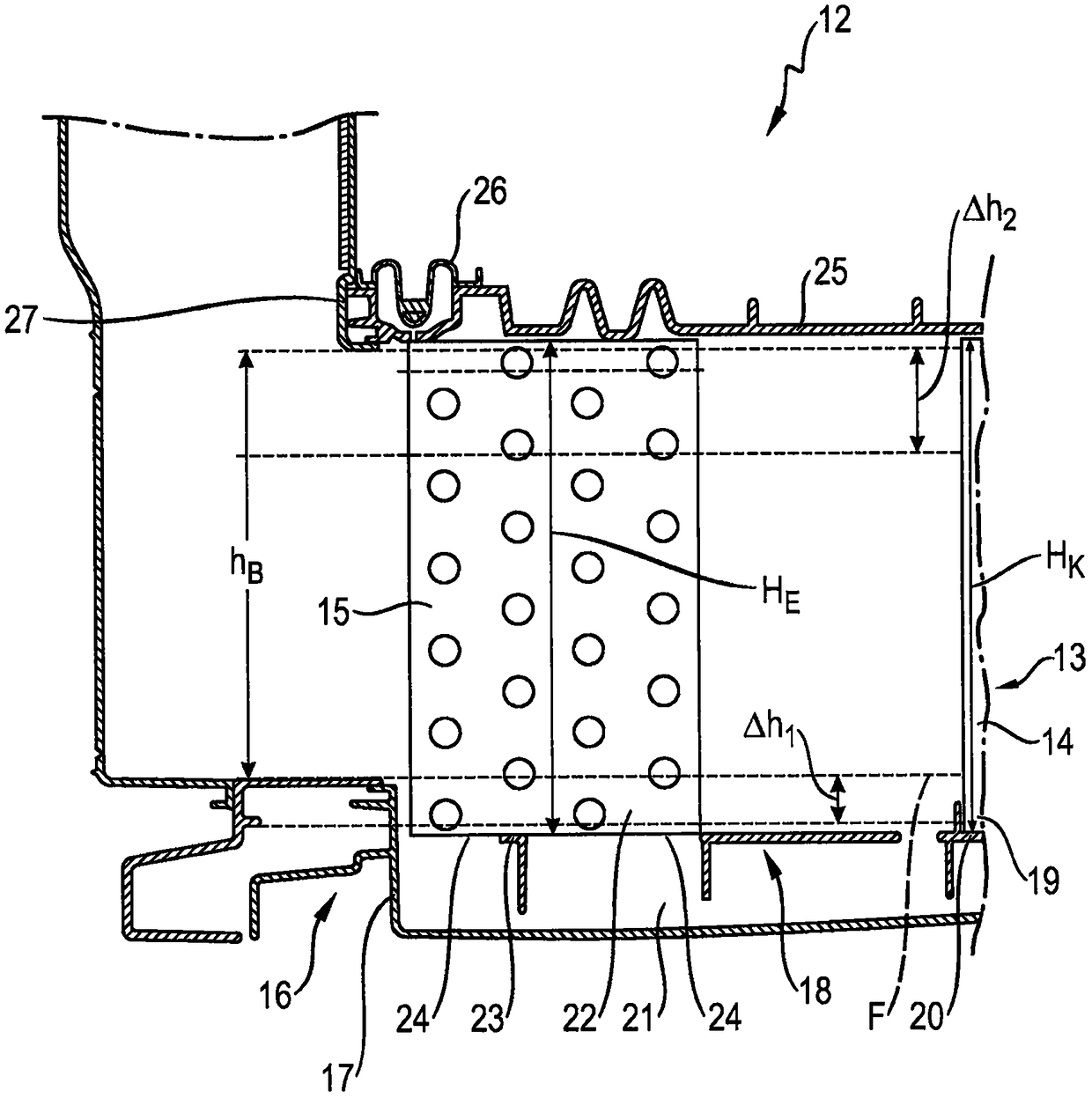

[0030] figure 2 Shown is a schematic sectional view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com