Water catching device and water catching method for flue gas produced in coal-fired power plant

A coal-fired power plant, flue gas technology, applied in the direction of separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem of lack of flue gas water catcher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

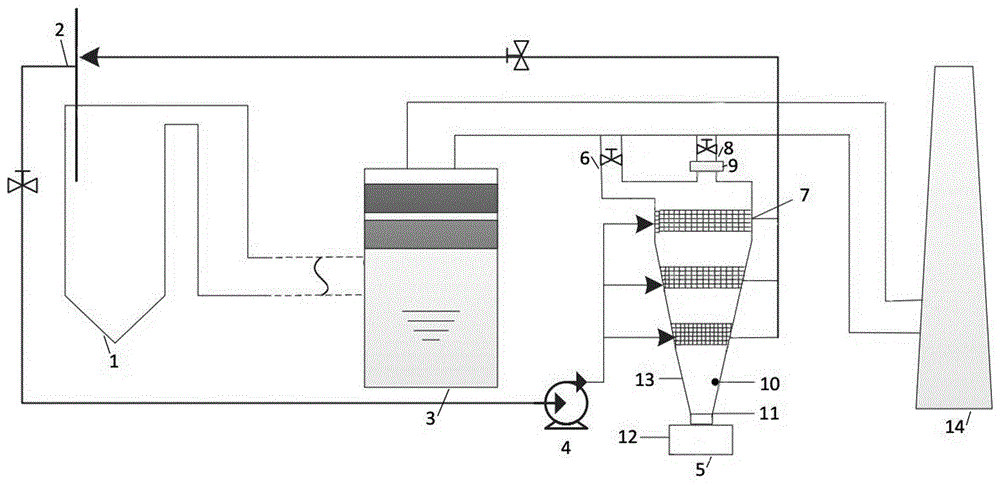

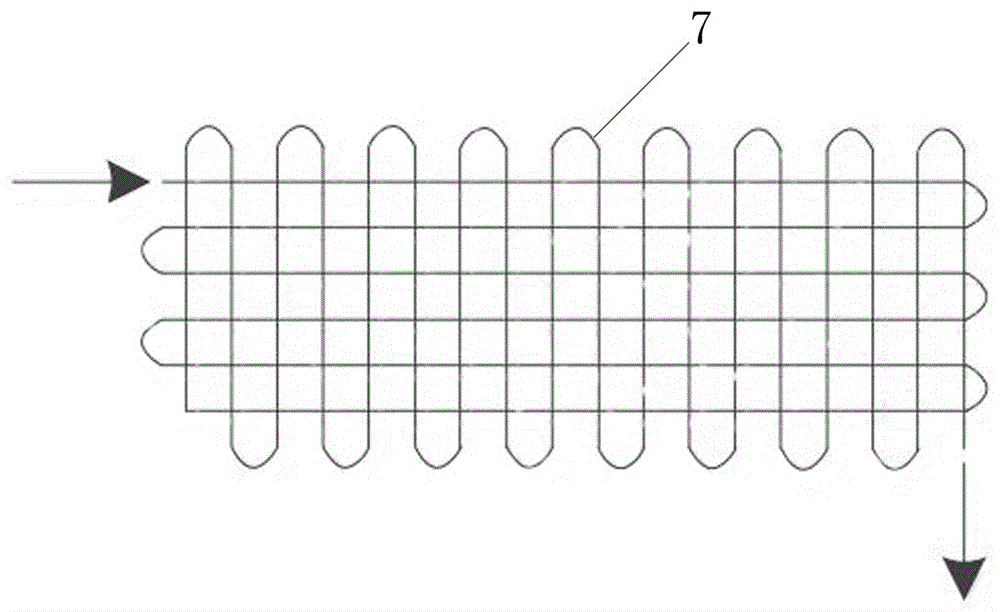

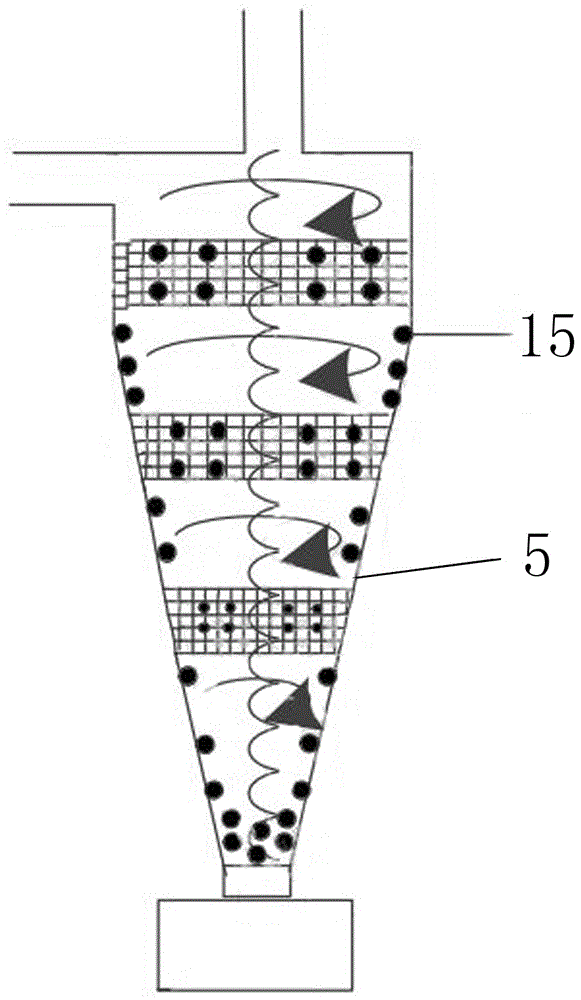

[0023] A coal-fired power plant flue gas water catcher, see Figure 1-2 , including a cyclone, the side wall of the cyclone is provided with an inlet pipe, the upper end of the cyclone is provided with an exhaust pipe, and the connection between the exhaust pipe and the cyclone is provided with a second induced draft fan. There is a multi-layer cooling pipe network inside the cyclone. The cooling pipe network is a multi-layer cross-arranged pipe, and the inlet of the cooling pipe network is connected to the conveying device.

[0024] The conveying device is the first induced draft fan, and the cold air of the first induced draft fan is drawn from the boiler intake air, and the cold air returns to the boiler intake air system after heat exchange and heating. Alternatively, the conveying device is a water pump, and the cooling water medium of the water pump is drawn from the boiler feed water, and the cooling water returns to the boiler water replenishment system after heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com