Process and system for re-refining unqualified liquid ammonia in oil refinery wastewater production

A technology of refinery wastewater and qualified liquid, which is applied in the field of re-refining system and operation process, can solve the problems of unstable and difficult liquid ammonia production and impurity content, avoid repeated heating and cooling, reduce waste heat discharge, and process flexible and efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

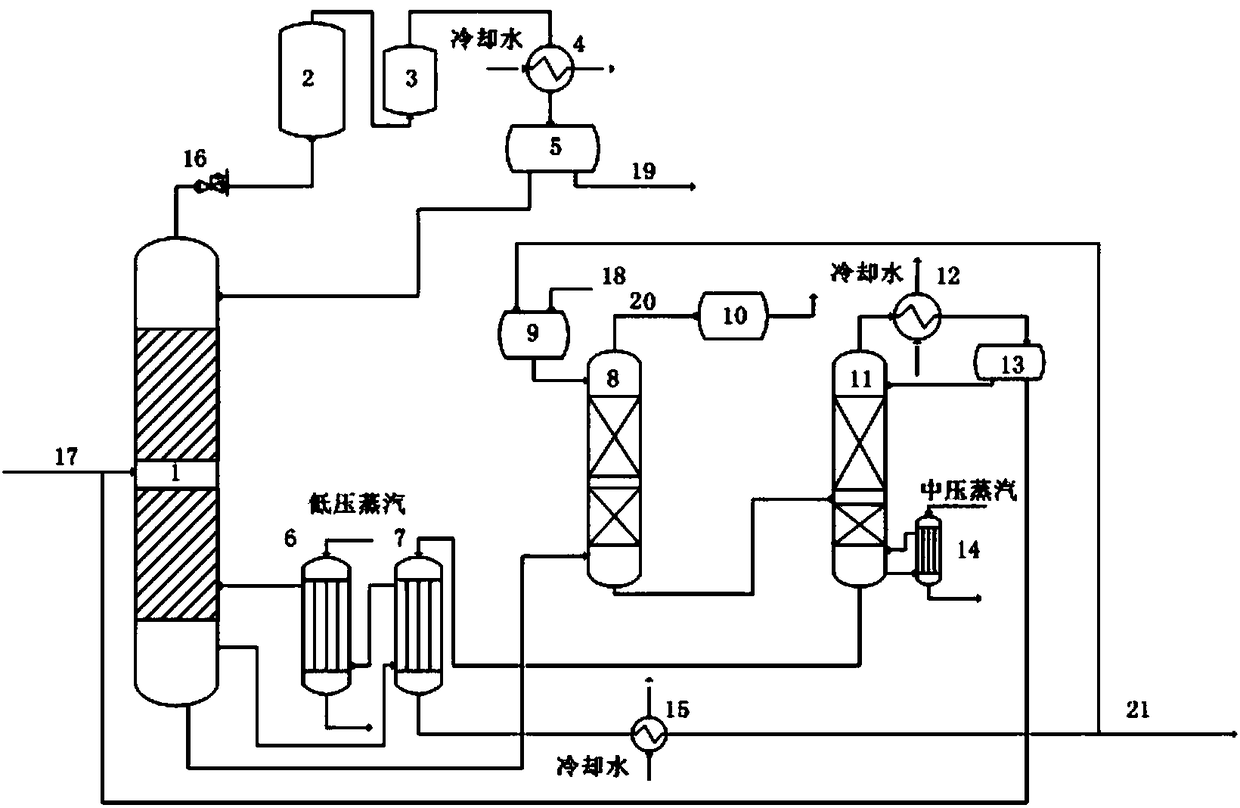

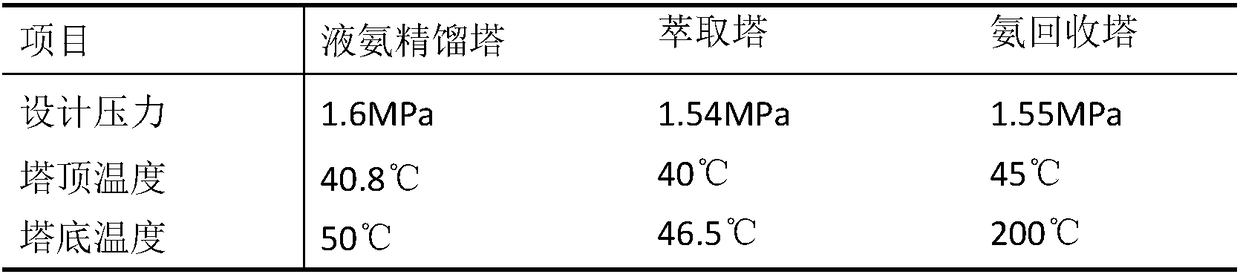

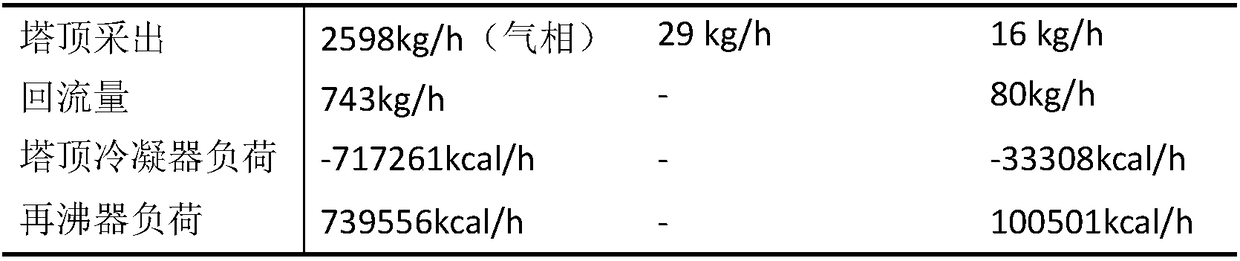

[0041] In order to illustrate the re-refining system and process of refining waste liquid ammonia of the present invention, the specific operation steps and instructions are as follows:

[0042] About 15,000 tons / year of unqualified liquid ammonia products in an oil refinery, the composition is liquid ammonia (wt%) 98%, C 5 -C 7 Light oil, water and phenolic residues total (wt%) 2%, hydrogen sulfide 50ppm, adopt the re-refining system of this application to purify liquid ammonia.

[0043] (1) 1900kg / h unqualified liquid ammonia 17 enters the liquid ammonia rectification tower 1, heats through the first-stage reboiler 7 of the liquid ammonia rectification tower, and the second-stage reboiler 6 heats with low-pressure steam to separate oil, water, and phenolic impurities.

[0044] (2) After refining, the ammonia gas with a purity of 99.8% is decompressed from the top of the tower to 1.58MPa by the pressure reducing valve 16 and enters the primary adsorption tank 2, and is adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com