Method for refining and purifying RB (Rebaudioside B)

A technology for refining products, stevia extracts, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve problems such as insufficient research, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

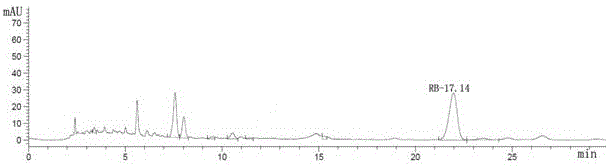

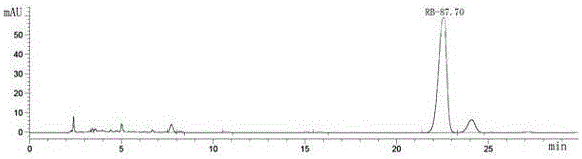

[0025] Take 100ml of gel-type cation exchange resin and put it into the chromatographic column, and pretreat the resin according to the following steps: use 2BV 4% hydrochloric acid to pass through the cation exchange resin, wash with water until the pH is 6.65; then use 2BV 4% sodium hydroxide aqueous solution to pass The cation exchange resin is washed with water until the pH is 8.52; finally, 2BV of 4% hydrochloric acid is passed through the cation exchange resin, and 5BV of water is used for washing. Take 70g rich in RB stevioside (stevia rebaudiana extract) (total glycoside sugar content is 69.92%, of which RB content is 17.14%, see figure 1 ) dissolved in water. Pass the high RB solution through the chromatographic column and collect the effluent, stand to crystallize at 4°C, and filter and separate after 72 hours to obtain RB stevioside (93.43% of the total glycoside content, of which RB content is 87.70%, see figure 2 ).

Embodiment 2

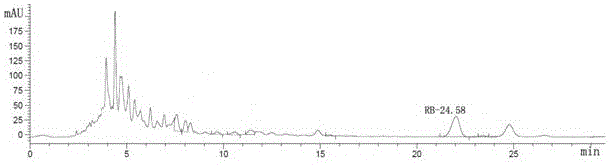

[0027] Take 100ml of macroporous cation exchange resin and put it into the chromatographic column, and pretreat the resin according to the following steps: use 2BV 4% hydrochloric acid to pass through the cation exchange resin, wash with water until the pH is 6.37; then use 2BV 4% sodium hydroxide aqueous solution to pass The cation exchange resin is washed with water until the pH is 8.74; finally, 4BV of 4% hydrochloric acid is passed through the cation exchange resin, and 8BV of water is used for washing. Take 100g rich in RB stevioside (stevia rebaudiana extract) (total glycosidic sugar content is 59.46%, wherein RB content is 24.58%, see image 3 ) dissolved in water. Pass the high RB solution through the chromatographic column and collect the effluent, stir at -4°C at 20r / s to precipitate crystals, filter and separate after 36h, and obtain RB stevioside (the total glycoside content is 96.25%, and the RB content is 90.66% ,See Figure 4 ).

Embodiment 3

[0029] Take 100g rich RB stevioside (stevia extract) (total glycoside sugar content is 74.91%, of which RB content is 57.59%, see Figure 5 ) dissolved in water. Add 30ml of 4% hydrochloric acid to the high RB solution, stir at 40r / s at 10°C to precipitate crystals, and filter and separate after 12h to obtain RB stevia (the total glycoside content is 90.39%, of which RB content is 85.85%, see Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com