Super wear-resistant water-lubricated bearing composite material and preparation method thereof

A technology of water-lubricated bearings and composite materials, which is applied in the field of super-wear-resistant water-lubricated bearing composite materials and its preparation, can solve the problems of large bearing wear, improve dry wear resistance, improve interface bonding, and reduce dry friction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

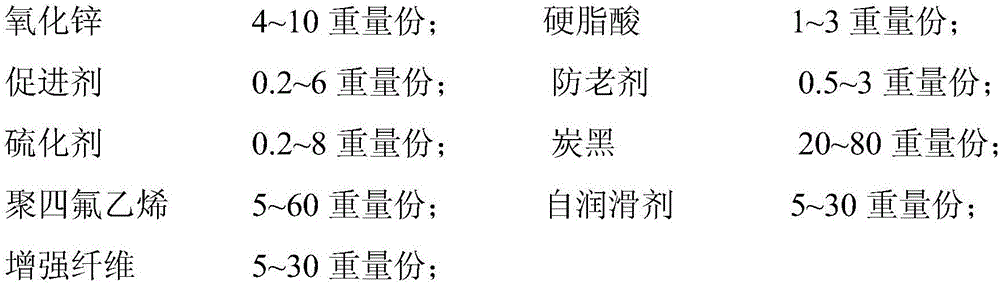

Method used

Image

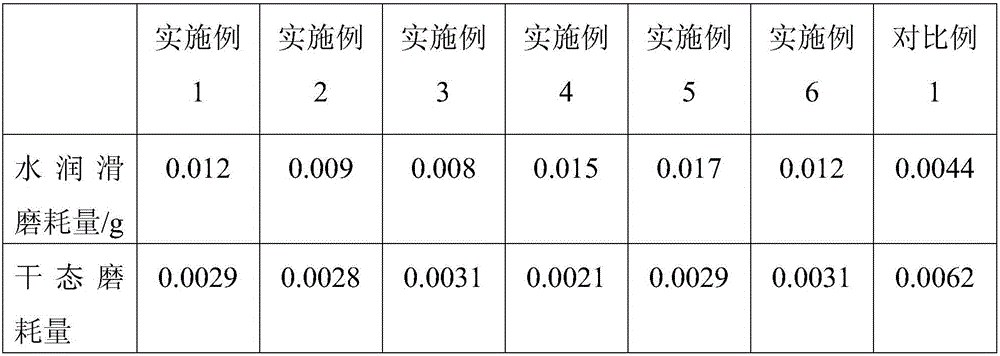

Examples

Embodiment 1

[0026] The super wear-resistant water-lubricated bearing composite material consists of 80 parts by weight of nitrile rubber, 20 parts by weight of polyurethane rubber (number average molecular weight: 20,000), 4 parts by weight of zinc oxide, 1 part by weight of stearic acid, trimethylol trimethacrylate 0.8 parts by weight of propyl propane ester, 2 parts by weight of dicumyl peroxide, 50 parts by weight of carbon black, 0.5 parts by weight of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, polytetrafluoroethylene It is composed of 5 parts by weight of vinyl fiber (γ-ray radiation under 30KGy dose), 30 parts by weight of graphite and 15 parts by weight of carbon fiber.

[0027] The preparation method of the above super wear-resistant water-lubricated bearing composite material: firstly add nitrile rubber, polyurethane rubber (number average molecular weight 20,000), zinc oxide, stearic acid, carbon black, 2,2,4 -Trimethyl-1,2-dihydroquinoline polymer, polytetrafluoroethylene fi...

Embodiment 2

[0029] Super wear-resistant water-lubricated bearing composite material, consisting of 40 parts by weight of hydrogenated nitrile rubber, 60 parts by weight of polyurethane rubber (number average molecular weight: 40,000), 10 parts by weight of zinc oxide, 3 parts by weight of stearic acid, di-tert-butyl peroxide 8 parts by weight of dicumylbenzene, 0.2 parts by weight of triallyl isocyanurate, 20 parts by weight of carbon black, 1 part by weight of N-isopropyl-N'-phenyl-p-phenylenediamine, polytetrafluoroethylene It is composed of 60 parts by weight of vinyl fibers (electron beam irradiation at a dose of 300KGy), 5 parts by weight of molybdenum disulfide and 10 parts by weight of glass fibers.

[0030] The preparation method of the above-mentioned super wear-resistant water-lubricated bearing composite material: firstly add hydrogenated nitrile rubber, polyurethane rubber (number average molecular weight 40,000), zinc oxide, stearic acid, carbon black, N-isopropyl Base-N'-phe...

Embodiment 3

[0032] Super wear-resistant water-lubricated bearing composite material, consisting of 50 parts by weight of carboxylated nitrile rubber, 50 parts by weight of polyurethane rubber (number average molecular weight 80,000), 5 parts by weight of zinc oxide, 2 parts by weight of stearic acid, 1 part by weight of zinc dimethacrylate Parts by weight, 1 part by weight of triallyl isocyanurate, 1 part by weight of dicumyl peroxide, 3 parts by weight of dicumyl di-tert-butyl peroxide, 40 parts by weight of carbon black, 2,2 , 1 weight part of 4-trimethyl-1,2-dihydroquinoline polymer, 2 weight parts of N-isopropyl-N'-phenyl-p-phenylenediamine, polytetrafluoroethylene powder (3000KGy dose electron beam radiation) 25 parts by weight, 5 parts by weight of carbon nanotubes and 30 parts by weight of aramid fibers.

[0033] The preparation method of the above super wear-resistant water-lubricated bearing composite material: firstly add carboxylated nitrile rubber, polyurethane rubber (number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com