Glass cutting fluid

A cutting fluid and glass technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as environmental damage, unfavorable water environment treatment and protection, water eutrophication, etc., to reduce irritation, reduce grinding burns, reduce The effect of the amount added

Active Publication Date: 2017-05-17

广东山之风环保科技有限公司

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The additives in some cutting fluids can also cause harm to the environment. For example, in the patent with the authorized announcement number CN103275803 A, phosphorus-containing raw material phytate is used as a cleaning agent. This additive is easy to cause eutrophication of water bodies, which is not conducive Governance and Protection of Water Environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

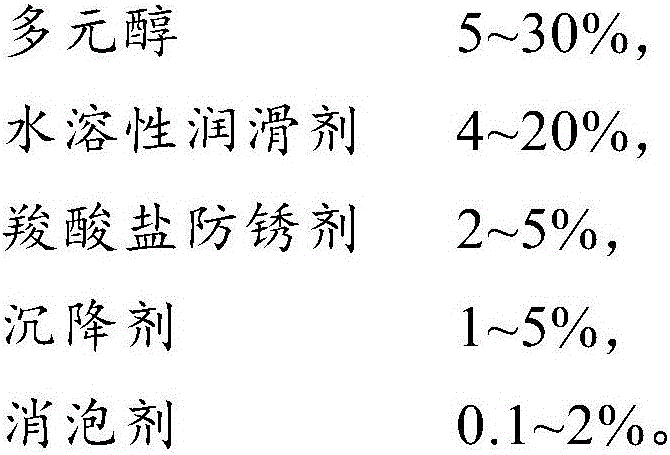

[0040] A kind of glass cutting fluid, the raw material composition by mass percentage is as follows:

[0041]

Embodiment 2

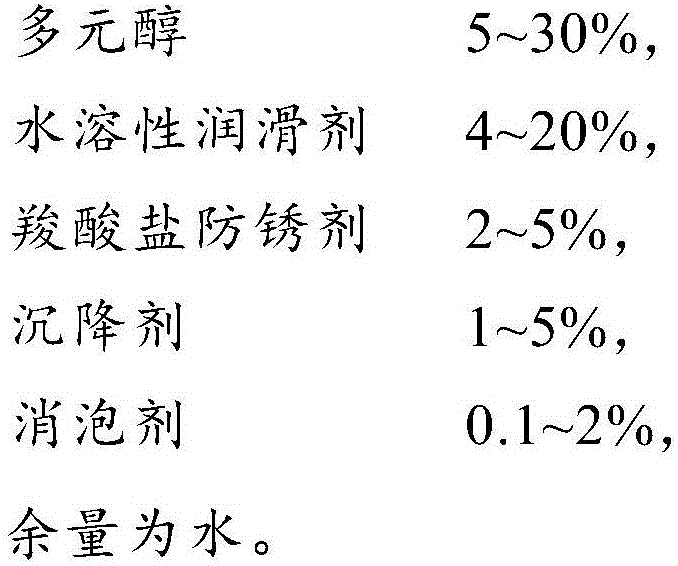

[0043] A kind of glass cutting fluid, the raw material composition by mass percentage is as follows:

[0044]

Embodiment 3

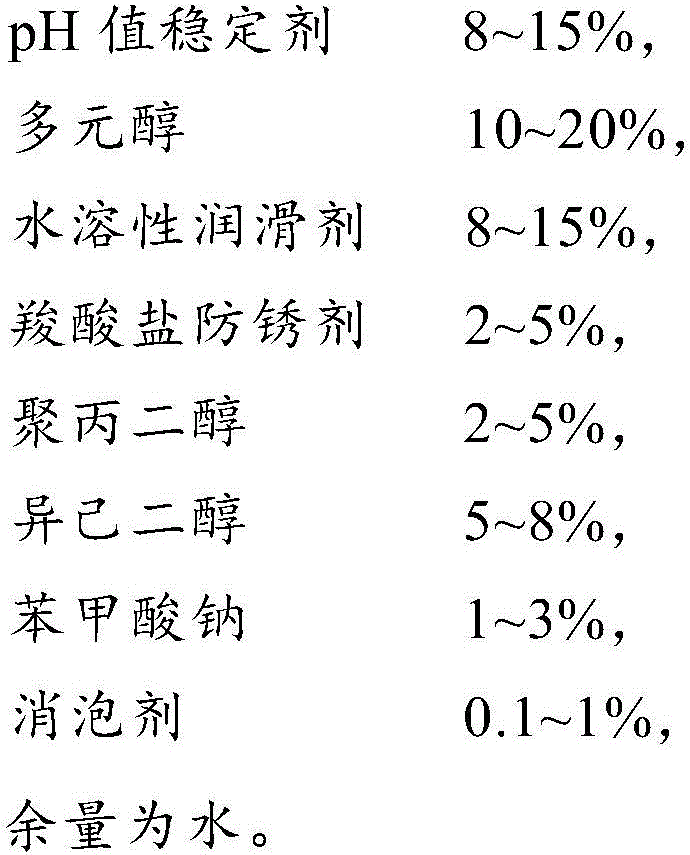

[0046] A kind of glass cutting fluid, the raw material composition by mass percentage is as follows:

[0047]

[0048]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a glass cutting fluid which comprises the following components: polyhydric alcohols, soluble lubricants, carboxylate antirust agents, sinking agents and de-foaming agents, wherein the components by weight percent include: 5-30% of polyhydric alcohols, 4-20% of soluble lubricants, 2-5% of carboxylate antirust agents, 1-5% of sinking agents and 0.1-2% of de-foaming agents. The glass cutting fluid provided by the invention has excellent lubricating, cooling, permeating and settling properties, meets the environmental requirements and the occupational safety and health requirements, expands the application of the glass cutting fluid in the halogen-free and phosphor-free fields, and is environment-friendly.

Description

technical field [0001] The invention relates to the technical field of glass processing, in particular to a glass cutting fluid. Background technique [0002] The processing of mobile phone cover glass and optical lens glass belongs to the high-end field of glass processing, especially the development of modern touch screen display technology and imaging technology, which has formed the "high processing precision, high production efficiency and high quality" of mobile phone touch screen glass processing and optical lens processing. The industry characteristics of "yield rate" and the processing conditions are developing in the direction of "high spindle speed, high feed speed, and large spray pressure". Therefore, higher requirements are put forward for the processing performance of glass cutting fluid. [0003] Glass is a hard and brittle non-metallic material, and cutting and grinding of glass products are usually carried out with diamond-encrusted cutters and grinding hea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M173/02C10N30/06C10N30/12C10N30/18

CPCC10M173/02C10M2207/022C10M2207/127C10M2207/141C10M2209/104C10M2209/105C10M2215/042C10M2227/04C10M2229/04C10N2030/06C10N2030/12C10N2030/16C10N2030/18C10N2030/64

Inventor 董恩莲严定龙

Owner 广东山之风环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com