Method for accelerating dry red wine ageing by instantaneous ultra-high pressure homogenization technology

A dry red wine, ultra-high pressure homogenizer technology, applied in the field of wine aging process, can solve the problems of discordant flavor structure, wine oxidation, poor clarity of wine body, etc. Increase and improve the effect of flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The newly brewed dry red wine was poured into the instantaneous ultra-high pressure feed port for instantaneous high-pressure treatment at a pressure of 100 and 200 MPa. Each wine sample was processed 1, 2, and 3 times under the two pressures respectively to obtain 6 groups of different wines. Treatment conditions, the treatment speed is maintained at 4-6L / h, the temperature of the wine liquid is controlled at 5-20°C by a cold water bath during the treatment process, no pressure is used as a control, and 3 parallels are made for each group, and the wine samples are preserved after treatment to be tested;

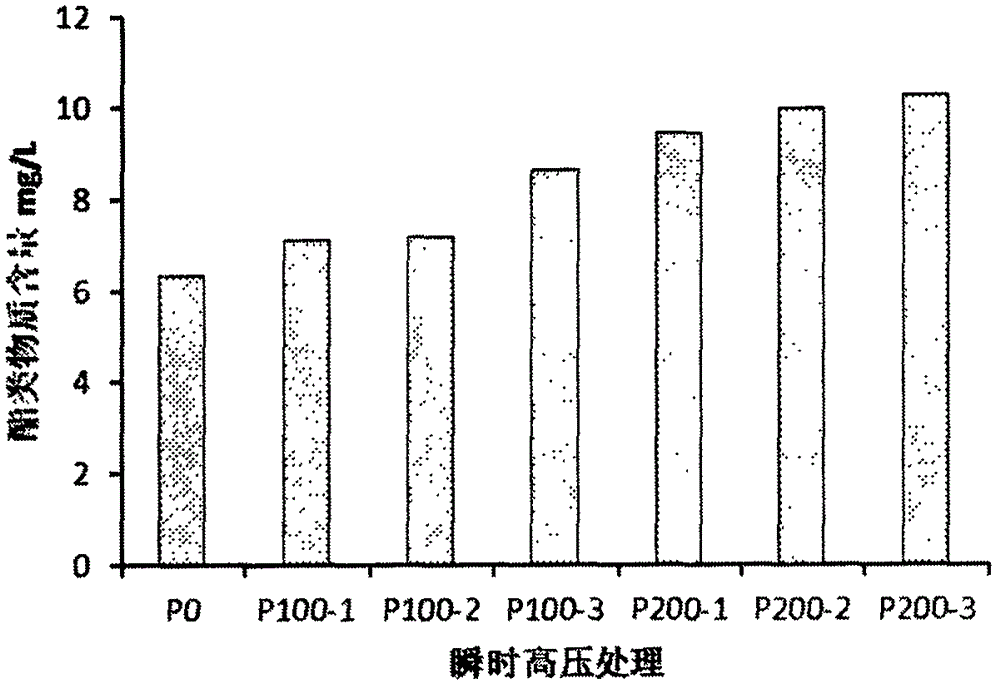

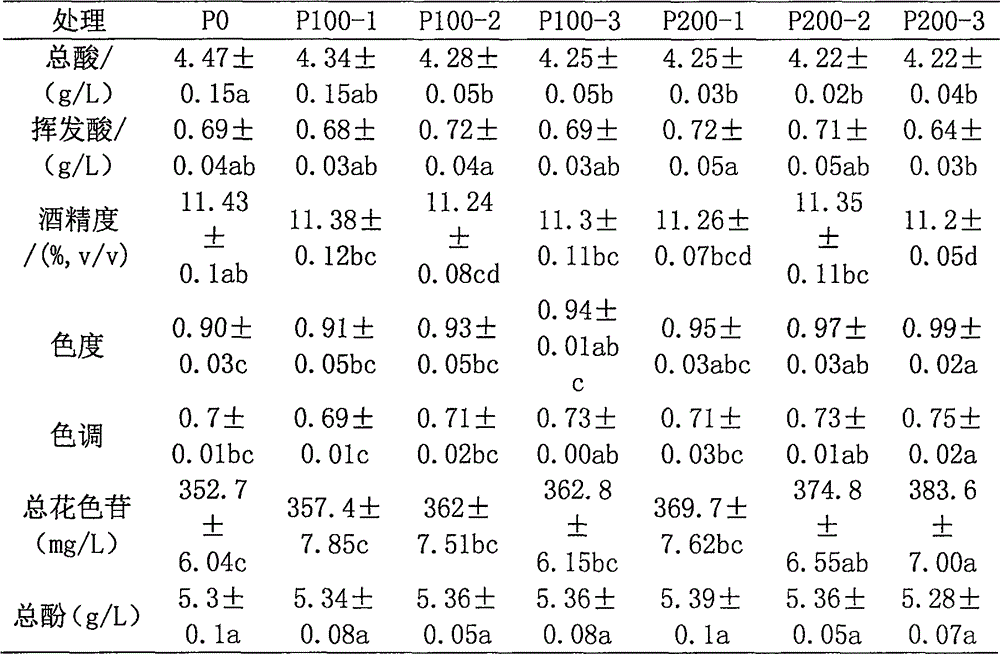

[0024] Treating Cabernet Sauvignon dry red wine with instantaneous ultra-high pressure, the physical and chemical indicators and aroma components of the wine changed to some extent. With the increase of treatment pressure and homogenization times, the total acid content and alcohol content of wine decreased, the total anthocyanin content, chroma, and hue value increas...

Embodiment 2

[0034]Instantaneous ultra-high pressure treatment of Merlot rosé wine, the pressure is 100-200MPa, the treatment cycle is 1-3 times, the treatment flow rate is 4-6L / h, the temperature of the wine liquid is between 5-20°C, and the esters increase after treatment 5 types, 7 types of alcohols, and 4 types of acids were reduced, and the main volatile substances such as ethyl acetate, ethyl caprylate, ethyl caprate, trans-4-decenoic acid ethyl ester, isoamyl alcohol, etc. The relative content of aroma substances changed significantly, indicating that ultra-high pressure treatment can improve the aroma of Merlot rosé wine. The comprehensive analysis shows that two cycles under 200MPa ultra-high pressure can make the aroma of Merlot rosé wine richer and softer.

Embodiment 3

[0036] Carry out instantaneous ultra-high pressure treatment on Guirenxiang dry white wine, the pressure is 100-200MPa, cycle treatment 1-3 times, the treatment flow rate is 4-6L / h, the temperature of the wine liquid is between 5-20°C, after the treatment, Guirenxiang dry white wine The aroma components changed, the content of alcohols and acids decreased, and the content of esters and terpenes increased. Among them, the relative content of 1-pentanol, phenylethyl alcohol, isoamyl alcohol, ethyl octanoate, isoamyl acetate, ethyl n-hexanoate, octanoic acid and styrene changed significantly. The comprehensive analysis showed that one cycle treatment at 200MPa could make the aroma of Guirenxiang dry white wine richer and softer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com