Method for preparing ceramic oxide film of different colors on the surface of titanium alloy

A technology of ceramic oxidation and titanium alloys, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problem of single color of micro-arc oxidation ceramic film, and achieve the realization of diversified colors, good high temperature resistance, and easy operation. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

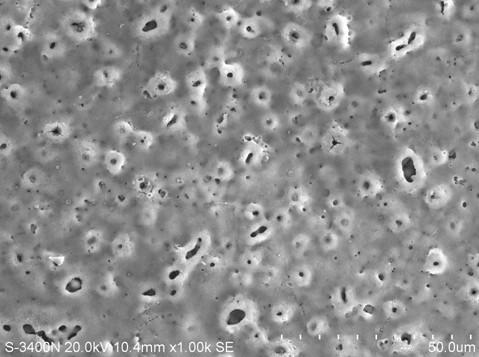

[0022] A preparation method for preparing an army green ceramic oxide film on the surface of a titanium alloy comprises the following steps:

[0023] 1. Pretreatment: first wash with hydrofluoric acid with a concentration of 5-30% to remove impurities on the surface of the titanium alloy sample, after washing with water for 10 minutes, soak in absolute ethanol for 30 seconds to remove the oil on the surface of the sample, and dry it;

[0024] 2. Electrolyte preparation: main salt 12-15g / L sodium phosphate, complexation stabilizer 8-10ml / L ammonia water, coloring agent 0.9-1.0g / L copper sulfate pentahydrate;

[0025] 3. The titanium alloy sample is used as the anode, the stainless steel tank is used as the cathode, and the anode is immersed in the prepared electrolyte; the DC pulse micro-arc oxidation equipment is used to perform micro-arc oxidation treatment on the titanium alloy sample, and the electrical parameters are set: voltage 330~ 350V, current 0.9-1.3A, frequency 270-...

Embodiment 2

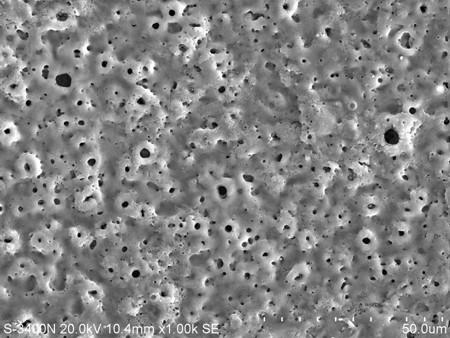

[0027] A preparation method for preparing an army green ceramic oxide film on the surface of a titanium alloy comprises the following steps:

[0028] 1. Pretreatment: first wash with hydrofluoric acid with a concentration of 5-30% to remove impurities on the surface of the titanium alloy sample, after washing with water for 10 minutes, soak in absolute ethanol for 30 seconds to remove the oil on the surface of the sample, and dry it;

[0029] 2. Electrolyte preparation: main salt 17-19g / L sodium phosphate, complexation stabilizer 9-12ml / L ammonia water, coloring agent 0.9-1.0g / L copper sulfate pentahydrate;

[0030] 3. The titanium alloy sample is used as the anode, the stainless steel tank is used as the cathode, and the anode is immersed in the prepared electrolyte; the DC pulse micro-arc oxidation equipment is used to perform micro-arc oxidation treatment on the titanium alloy sample, and the electrical parameters are set: voltage 300~ 320V, current 1.0-1.5A, frequency 290-...

Embodiment 3

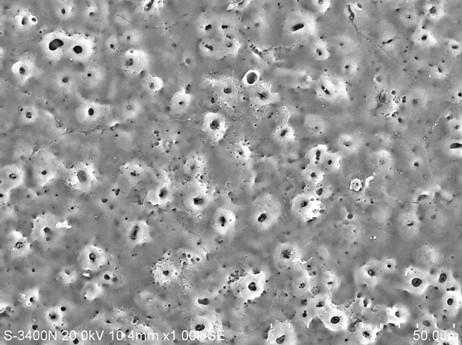

[0032] A preparation method for preparing a green ceramic oxide film on the surface of a titanium alloy comprises the following steps:

[0033] 1. Pretreatment: first wash with hydrofluoric acid with a concentration of 5-30% to remove impurities on the surface of the titanium alloy sample, wash with water for 10 minutes, then soak in absolute ethanol for 40 seconds to remove the oil on the surface of the sample, and dry it;

[0034] 2. Electrolyte preparation: the main salt is 8-10g / L sodium phosphate, the film-forming agent is 2-3g / L sodium fluoride, the film compaction accelerator is 2-3g / L sodium carbonate, and the complexation stabilizer is 2.5 ~4ml / L ammonia water, the coloring agent is 0.1~0.25g / L copper sulfate pentahydrate;

[0035] 3. The titanium alloy sample is used as the anode, the stainless steel tank is used as the cathode, and the anode is immersed in the prepared electrolyte; the DC pulse micro-arc oxidation equipment is used to perform micro-arc oxidation tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com