Water processor for clothes washing

A technology of clothes washing and water dispenser, which is applied to washing devices, other washing machines, water/sewage treatment, etc. It can solve the problems of stain precipitation in the washing machine, easy breeding of various bacteria, and residual ozone smell, etc., so as to enhance the washing effect and save energy. The use of water and washing time, the effect of reducing the damage to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

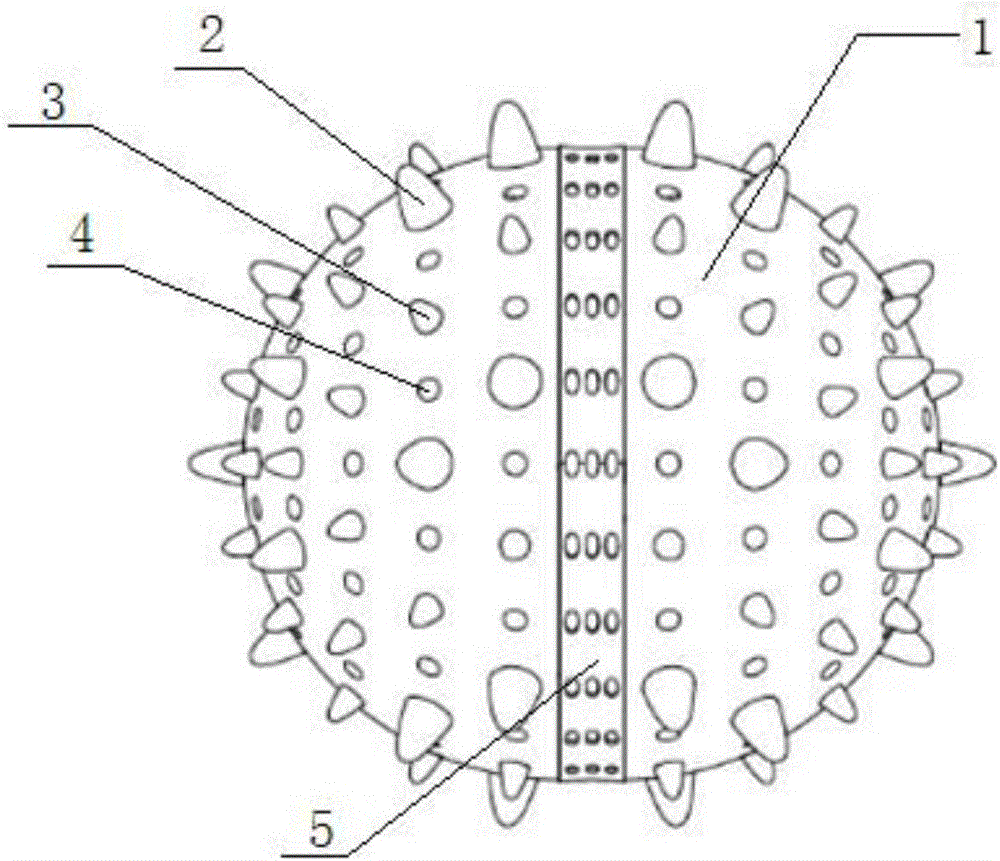

[0040] refer to figure 1 , a water conditioner for washing clothes, the water conditioner 1 is hollow spherical, the surface is provided with several water conditioners arranged with protrusions and hollow holes 4, and the center of the spherical surface of the water conditioner 1 is provided with a water inlet zone 5 , with a filter ball inside.

[0041] The protrusions are divided into large protrusions 2 and small protrusions 3, arranged in the order of large protrusions 2, hollow holes 4, and small protrusions 3.

[0042] The water inlet belt 5 is three hollow holes juxtaposed to form a water inlet, and the water inlet is arranged on the water inlet belt 5 in parallel.

[0043] The filter ball is made of antibacterial ceramic material and reduced antibacterial material in a mass ratio of 1:1.

[0044] The preparation method of described antibacterial ceramic material is:

[0045] Mix water and powder binder at a mass ratio of 3:1, and after stirring evenly, let stand fo...

Embodiment 2

[0051] refer to figure 1 , a water conditioner for washing clothes, the water conditioner 1 is hollow spherical, the surface is provided with several water conditioners arranged with protrusions and hollow holes 4, and the center of the spherical surface of the water conditioner 1 is provided with a water inlet zone 5 , with a filter ball inside.

[0052] The protrusions are divided into large protrusions 2 and small protrusions 3, arranged in the order of large protrusions 2, hollow holes 4, and small protrusions 3.

[0053] The water inlet belt 5 is three hollow holes juxtaposed to form a water inlet, and the water inlet is arranged on the water inlet belt 5 in parallel.

[0054] The filter ball is made of antibacterial ceramic material and reduced antibacterial material in a mass ratio of 1:1.

[0055] The preparation method of described antibacterial ceramic material is:

[0056] Mix water and powder binder at a mass ratio of 3:1, and after stirring evenly, let stand fo...

Embodiment 3

[0062] refer to figure 1 , a water conditioner for washing clothes, the water conditioner 1 is hollow spherical, the surface is provided with several water conditioners arranged with protrusions and hollow holes 4, and the center of the spherical surface of the water conditioner 1 is provided with a water inlet zone 5 , with a filter ball inside.

[0063] The protrusions are divided into large protrusions 2 and small protrusions 3, arranged in the order of large protrusions 2, hollow holes 4, and small protrusions 3.

[0064] The water inlet belt 5 is three hollow holes juxtaposed to form a water inlet, and the water inlet is arranged on the water inlet belt 5 in parallel.

[0065] The filter ball is made of antibacterial ceramic material and reduced antibacterial material in a mass ratio of 1:1.

[0066] The preparation method of described antibacterial ceramic material is:

[0067] Mix water and powder binder at a mass ratio of 3:1, and after stirring evenly, let stand fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com