Pressure-relieving and permeability-increasing method for drilling exploitation of ultra-thin coal seam

A very thin coal seam drilling and mining technology, which is applied in earthwork drilling, ground mining, underground mining, etc., can solve the problems of increasing the risk of gas outburst or water inrush, reducing the profit margin of coal mining, and increasing mining costs, etc. The effect of coal recovery rate, reduction of mining cost, and reduction of the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

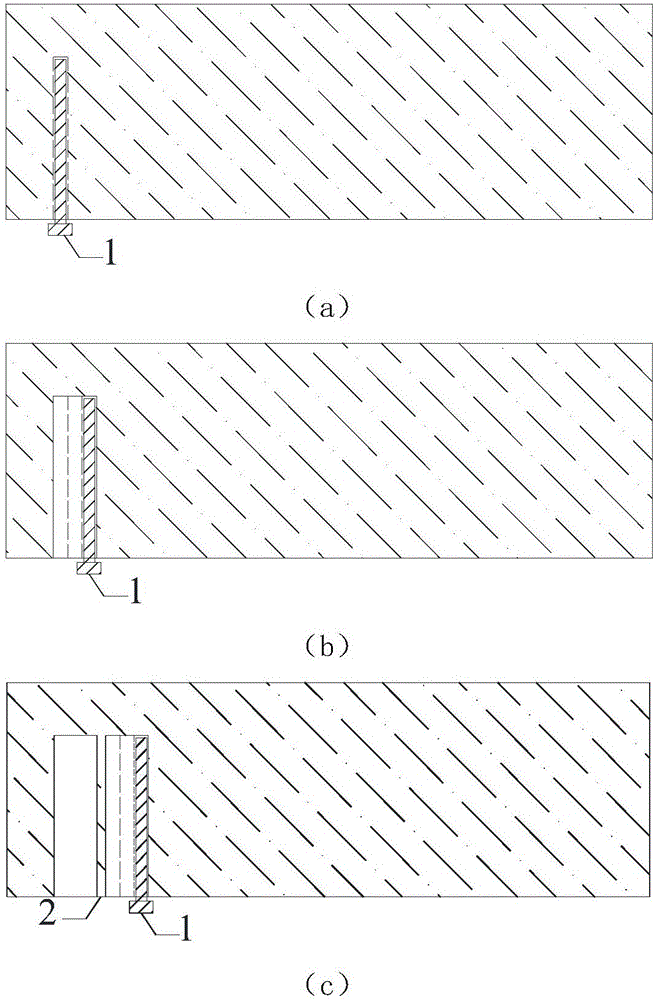

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

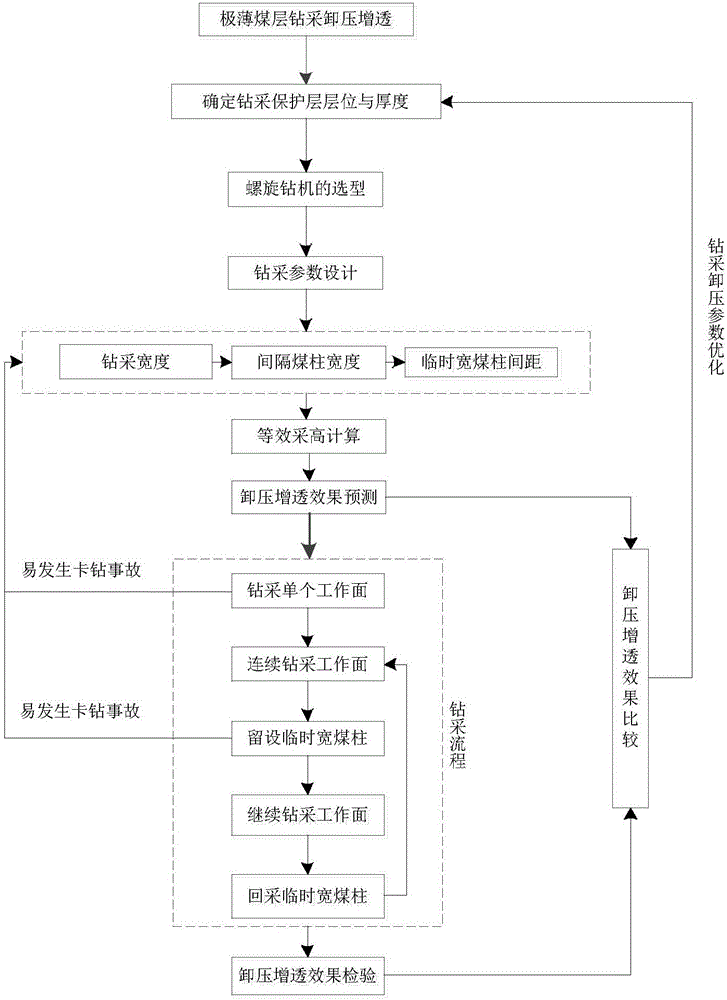

[0030] The present invention is a method for pressure relief and anti-reflection in ultra-thin coal seam drilling. The process flow is as follows: figure 1 As shown, the specific steps are as follows:

[0031] (1) According to the geological conditions of coal seam mining, in the coal seam group, the extremely thin coal seam with low gas content and pressure is selected as the first mining coal seam N for drilling.

[0032] (2) Collect the geological data of the first mining protection layer, design the drilling height and select the model of the auger shearer according to the occurrence change of the coal seam thickness and the drilling distance.

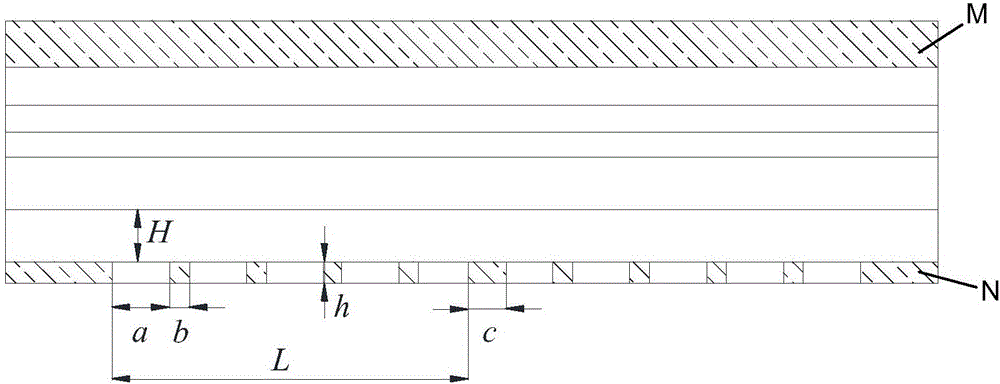

[0033] (3) Drilling parameters such as figure 2 Shown:

[0034] Drilling width a:

[0035]

[0036] In the formula: w, drilling width of auger rig 1; E, elastic modulus of the roof; H, thickness of the roof; △h, allowab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com