Geometric analysis method based functionally gradient material part modeling method

A technology of functionally graded materials and modeling methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, and achieve the effect of improving computing efficiency, eliminating node interpolation, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific steps of the functionally graded material part modeling method based on the isogeometric analysis method of the present invention are as follows:

[0035] 1. Establish a mathematical model of material distribution inside functionally graded material parts.

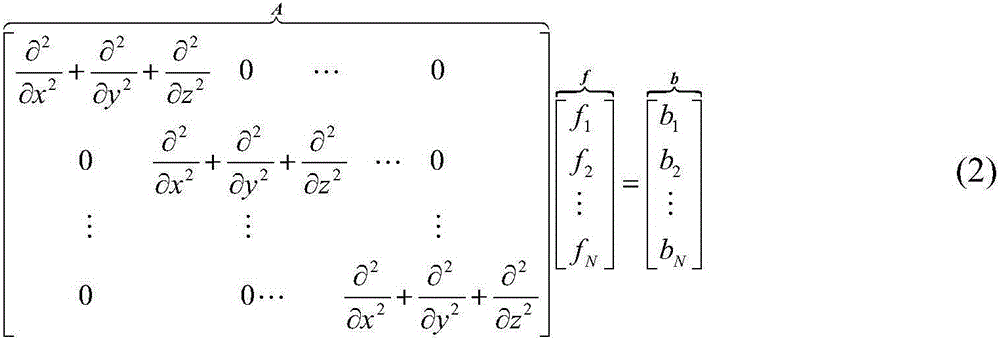

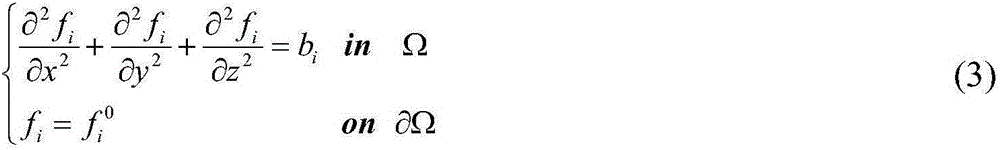

[0036] Taking the volume fraction f of each component material phase of the functionally graded material as the design variable, the material distribution state inside the part can be abstracted into the following mathematical model:

[0037]

[0038] Among them, A is the Laplacian differential operator matrix, f=[f 1 ,f 2 … f N ] is the corresponding volume fraction of N kinds of materials that make up functionally graded material parts, b=[b 1 ,b 2 …b N ] is the adjustment factor for the designer to control the material distribution inside the part, f 0 Represents the known material composition information at the boundary, Ω refers to the geometric space of the part, Refers to the boundary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com