Polymer electroluminescent wire

An electroluminescent wire and polymer technology, applied in the field of polymer electroluminescent wire, can solve the problems of light energy loss, gaps not being filled, and limited improvement in the brightness of the electroluminescent wire, etc., and achieve long service life , service life, safety and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

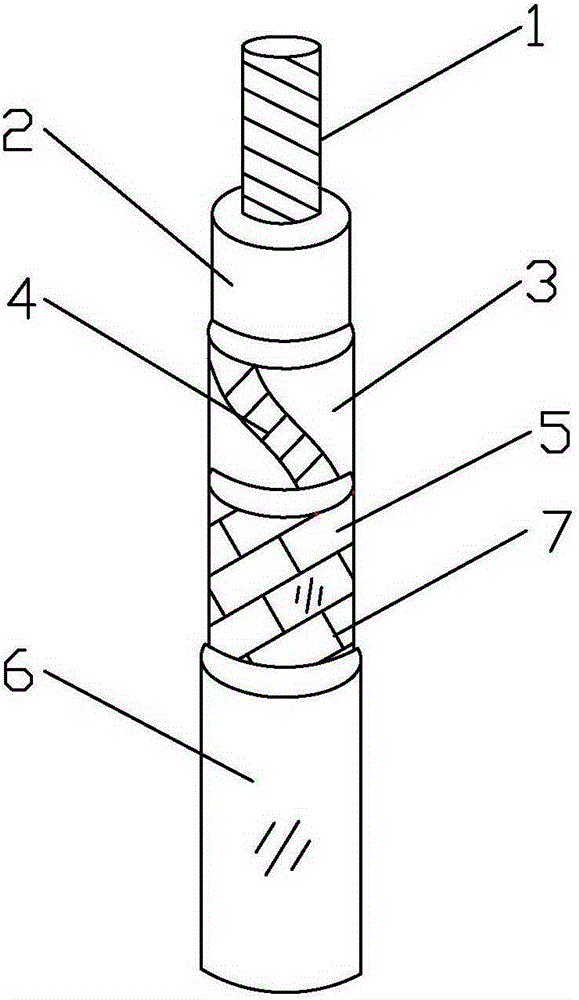

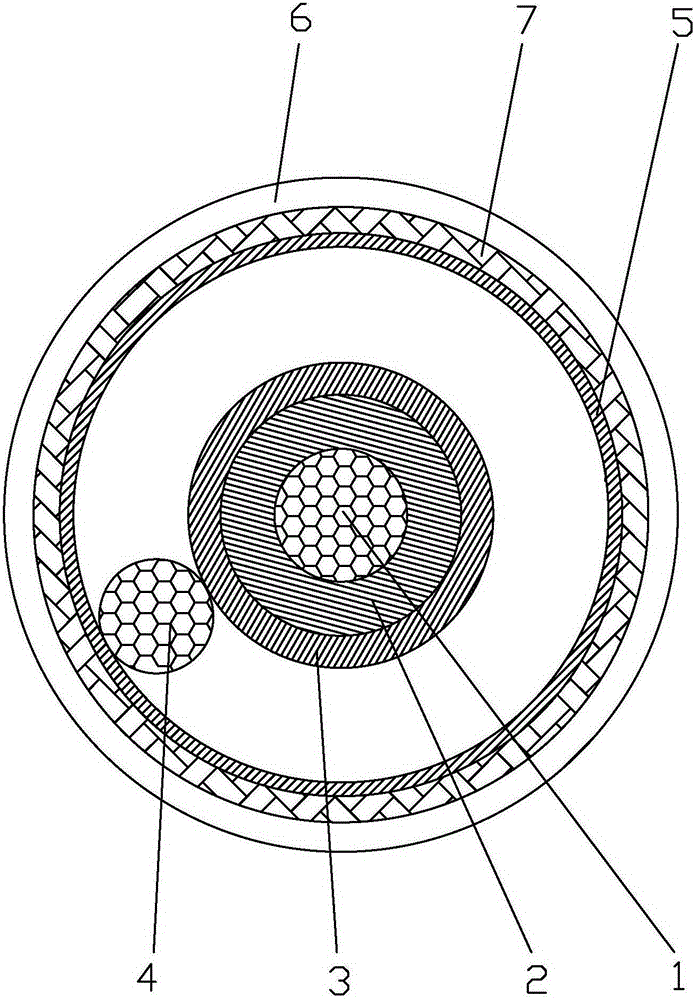

[0019] Such as figure 1 and figure 2 As shown, the polymer electroluminescent wire of the present invention includes a central electrode wire 1, a light-emitting layer 2, a light-transmitting conductive layer 3, an auxiliary electrode wire 4, a transparent polymer layer 5 and a transparent outer insulating layer 6, and the central electrode wire 1 It includes a linear conductor and is connected to the power controller. The light-emitting layer 1 is an insulating, conductive, and transparent polymer. The light-emitting layer 1 covers the central electrode line 1. The light-transmitting conductive layer 3 to cover the light-emitting layer 2, the auxiliary electrode line 4 includes a linear conductor, and is wound around the periphery of the light-transmitting conductive layer 3, and connected to the power controller, and the central electrode line 1 is connected to the auxiliary The polarity of the power line 4 is opposite to that connected to the power controller. For safety ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap