Bypass tube cleaner with slug flow control function

A technology for bypass pigging and slug flow, which is used in cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of pig speed fluctuations, insufficient pushing power, and large liquid plugs. , to extend the length of the liquid plug, enhance the liquid-carrying capacity, and reduce the running resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

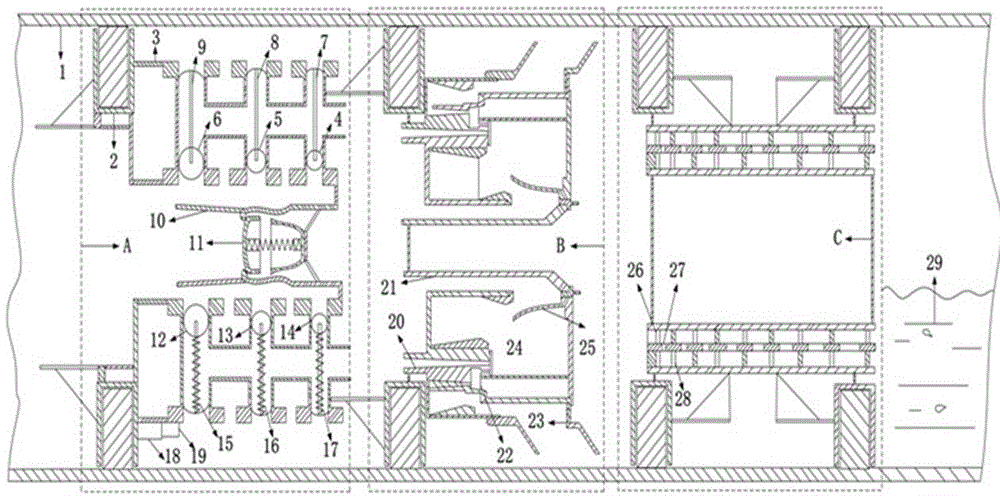

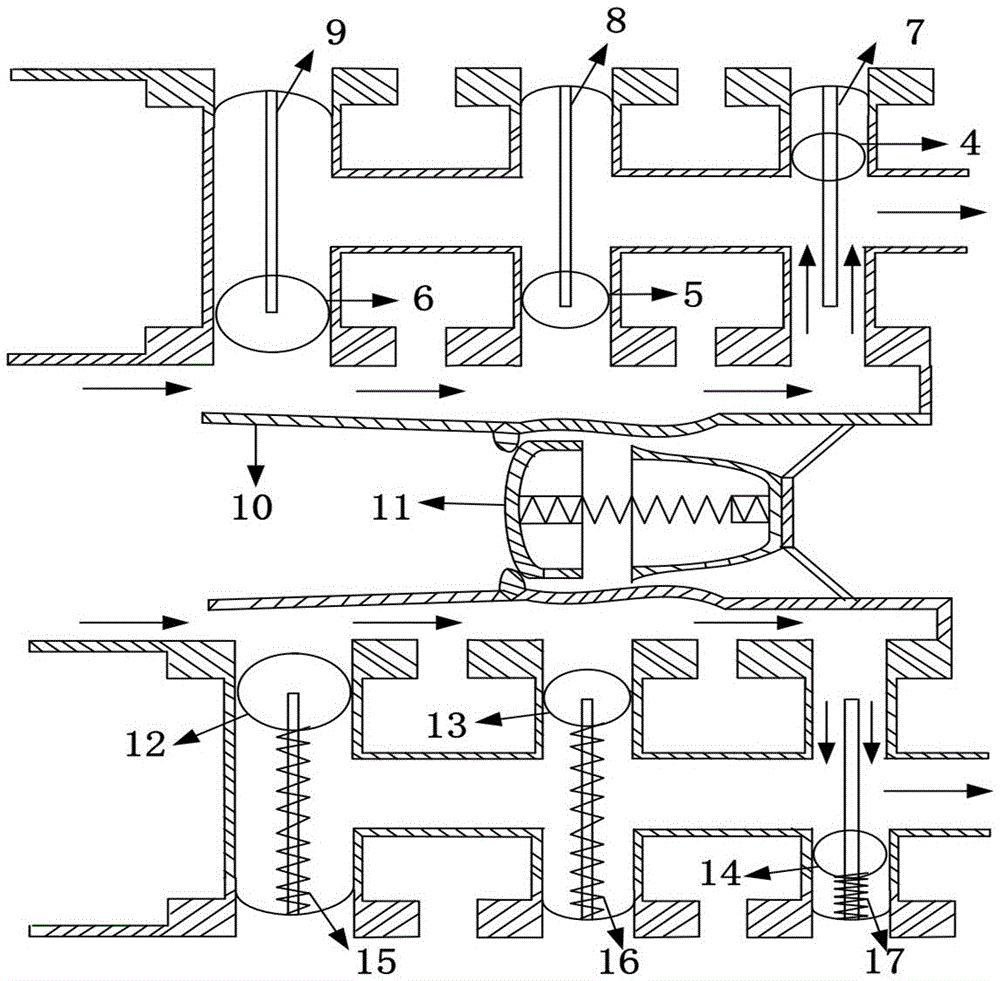

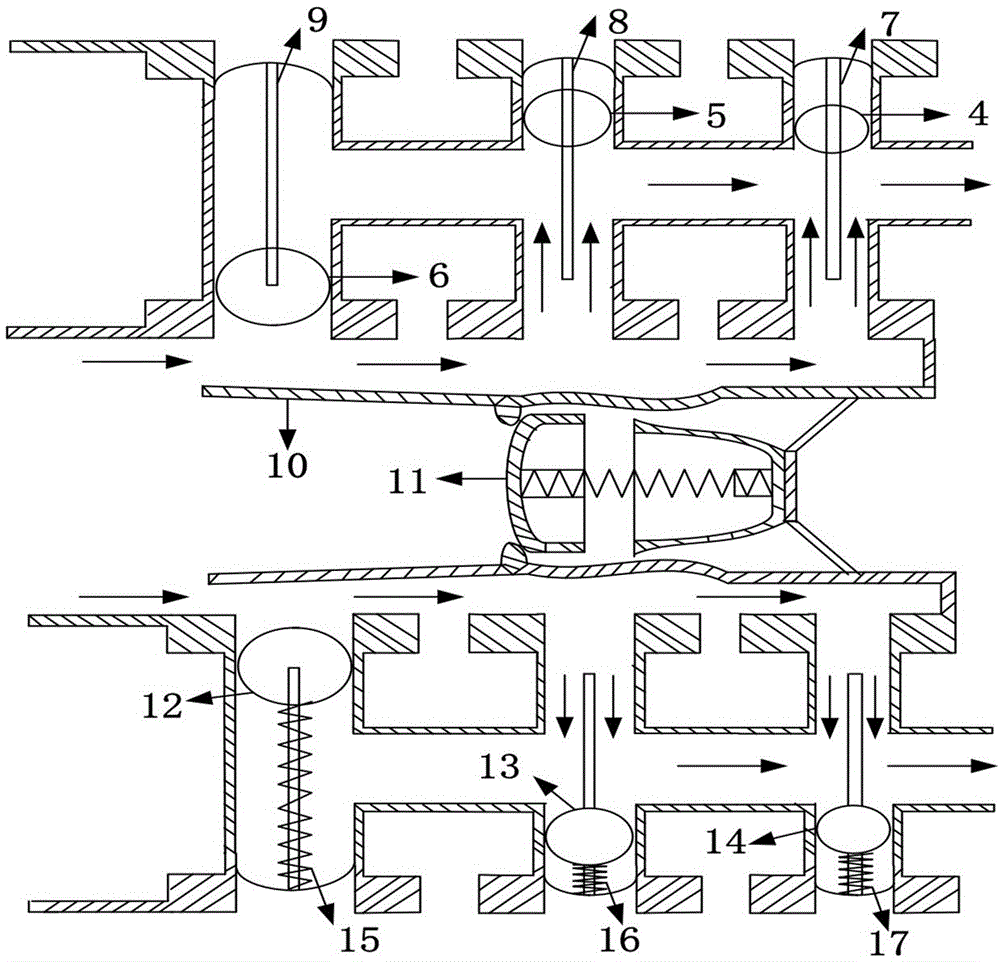

[0037] In this example, figure 1 Schematic diagram of bypass pig with slug flow control. Including pipeline inner wall 1, leather cup 2, steel frame 3, first bypass ball 4, second bypass ball 5, third bypass ball 6, first bypass rod 7, second bypass rod 8, second bypass rod Three bypass rods 9, central channel 10, central bypass ball 11, fourth bypass ball 12, fifth bypass ball 13, sixth bypass ball 14, fourth bypass rod 15, fifth bypass rod 16 , sixth bypass rod 17, electronic positioning receiver 18, electronic signal transmitter 19, tapered channel 20, high-pressure gas channel 21, atomization channel 22, gas outflow channel 23, cavity 24, one-way valve 25, the first A vortex unit 26 , a second vortex unit 27 , a third vortex unit 28 , and a pigging plug 29 .

[0038]Inside the pipeline inner wall 1 is a speed control chamber A, an atomization chamber B, and a vortex purge chamber C connected in sequence. In the speed control chamber A, a leather cup 2 is connected to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com