Tooling plate circular flow production line

A mobile production line and tooling board technology, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc., to achieve the effects of saving operating time, occupying a small area, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

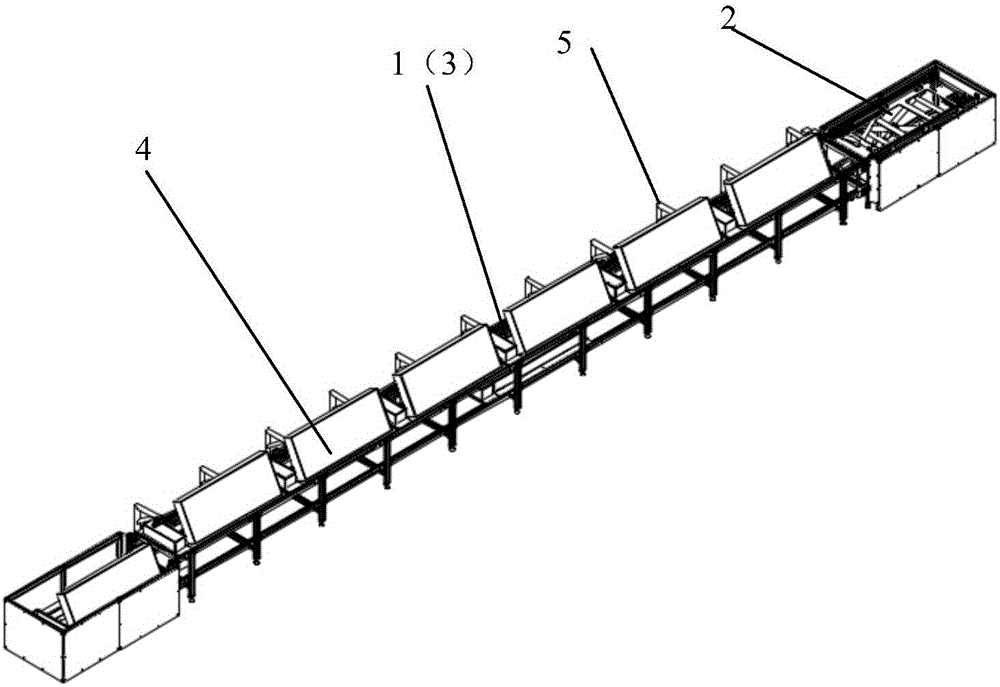

[0024] Such as figure 1 and 2 As shown, it is a three-dimensional structural schematic diagram of the tooling plate circulation production line of this embodiment.

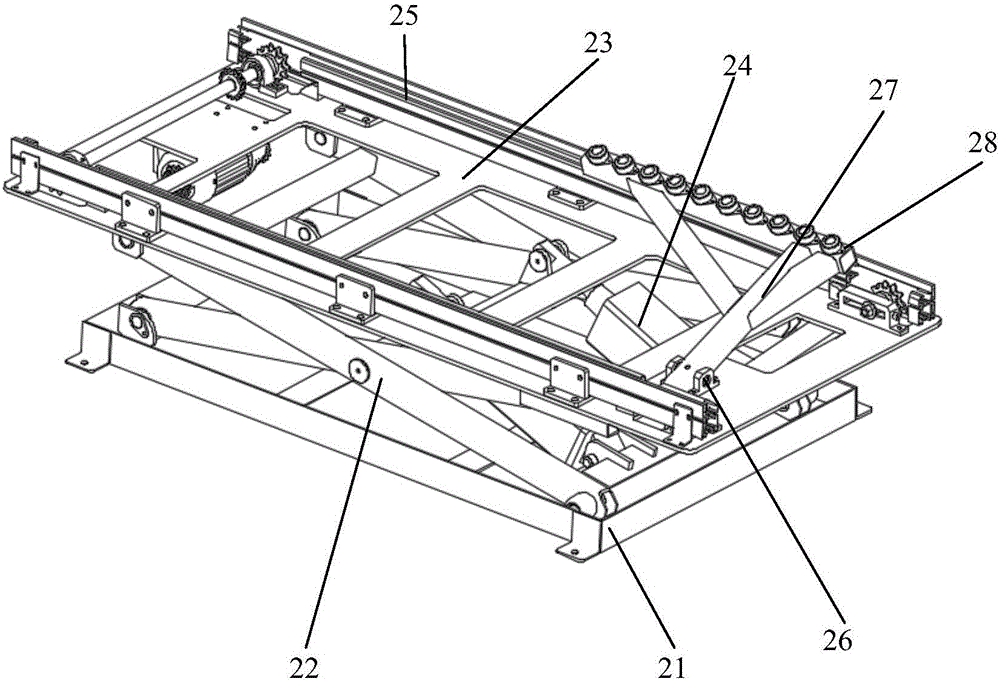

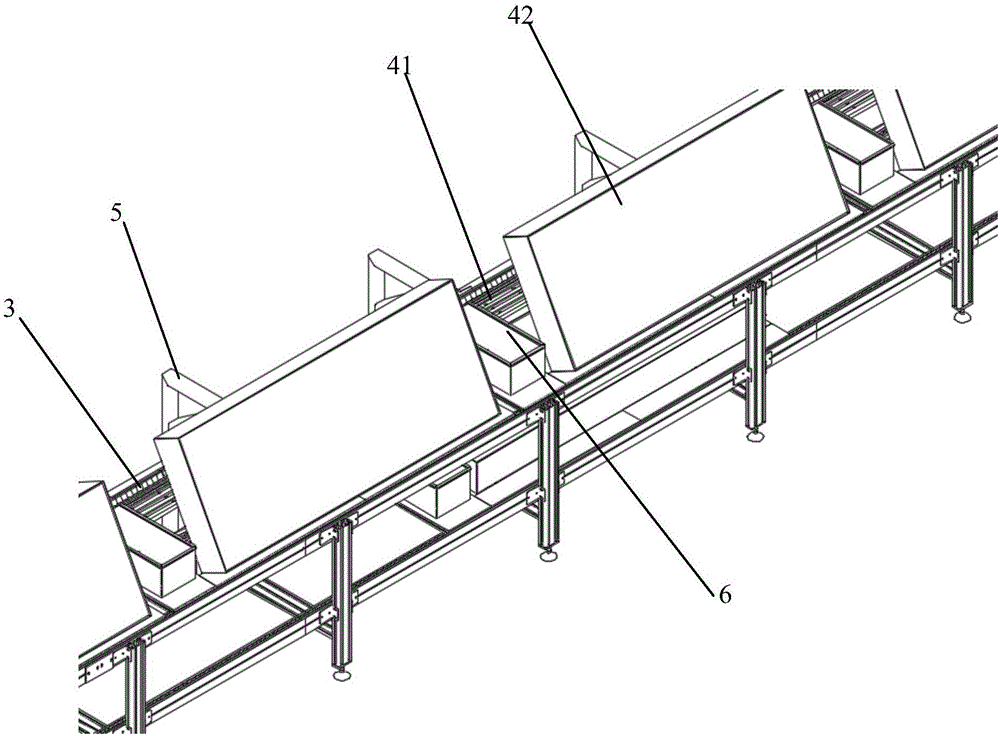

[0025] Such as figure 1 and 3 As shown, a tooling plate circulating flow production line includes two lifting mechanisms 1 , a frame 2 , a first conveyor belt 3 , a tooling plate mechanism 4 and a cantilever guide rod 5 .

[0026] The tooling plate circulating flow production line is arranged in a "one" shape, including the lifting mechanism 1 set at both ends of the entire production line, and the first conveyor belt 3 is set through the frame 1 between the two lifting mechanisms 2, and the first conveyor belt 3 The conventional product double-speed chain conveyor in the prior art is adopted. No less than one tool frame 6 for placing operation tools is arranged horizontally on the upper surface of the frame 1 . The tooling plate mechanism 4 is arranged on the working surface of the conveyor belt, and the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com