Activated carbon prepared from leaf residues of cinnamomum longepaniculatum and preparation method of activated carbon

A technology of camphor leaf residue and activated carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry and other directions, can solve the problems of environmental pollution, waste of resources, decay and the like, and achieve the effects of simple preparation method and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

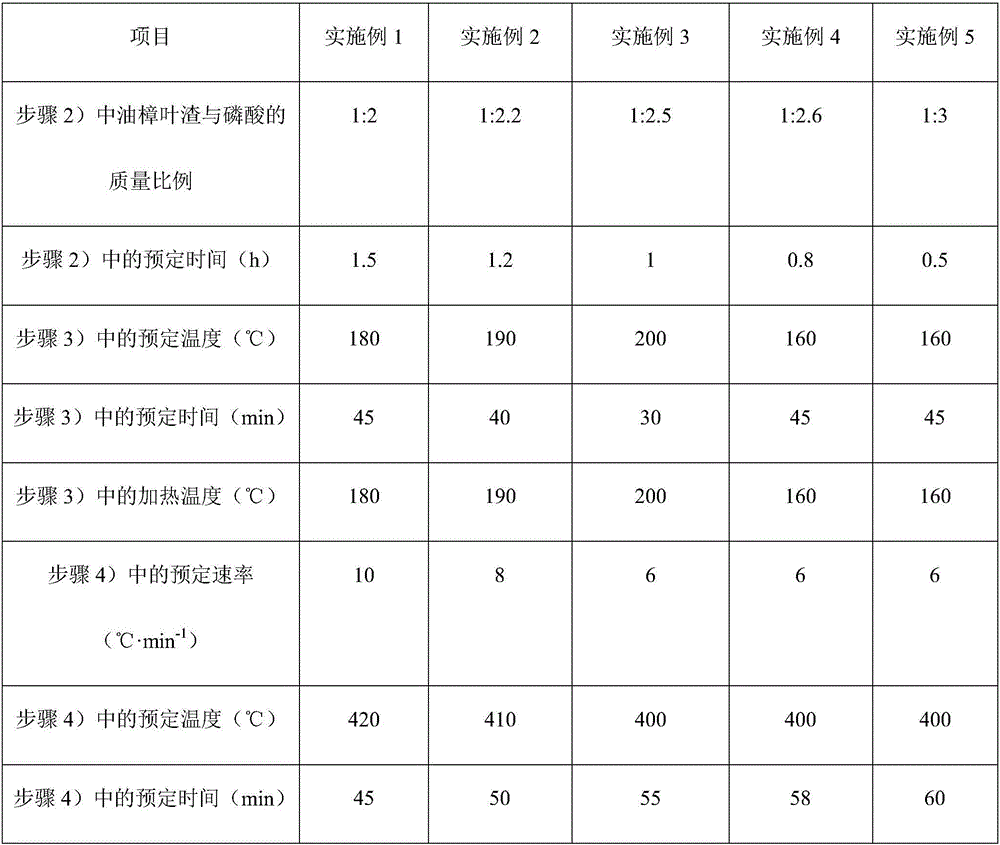

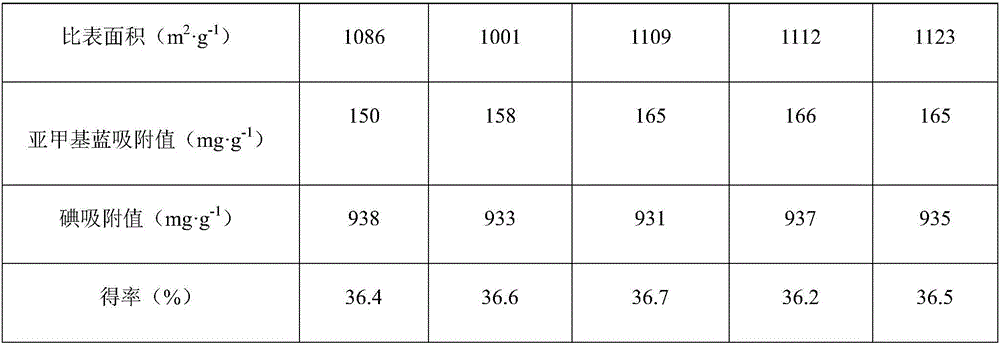

Embodiment 1

[0016] 1) crushing: crushing camphor leaf slag into uniform subsections;

[0017] 2) Impregnation: Mix the camphor leaf residue pulverized in step 1) with phosphoric acid with a concentration of 80% in a weight ratio of 1:2, and impregnate for 1.5 hours to obtain a mixture 1;

[0018] 3) Preactivation: Preactivate the mixture 1 obtained in step 2) at 180° C. for 45 minutes to obtain mixture 2;

[0019] 4) Activation: put the mixture 2 obtained in step 3) into the activation furnace, -1 Raise the temperature of the activation furnace to 420° C. to activate mixture 2 at 420° C. for 45 min to obtain mixture 3; and

[0020] 5) Washing and drying: the mixture 3 obtained in step 4) is cooled to room temperature, and the cooled mixture 3 is washed with water to neutrality, and then the neutral mixture 3 is dried to obtain a black solid that is made of camphor leaves Activated carbon prepared from slag.

Embodiment 2

[0022] 1) crushing: crushing camphor leaf slag into uniform subsections;

[0023] 2) Impregnation: Mix the camphor leaf residue pulverized in step 1) with phosphoric acid with a concentration of 80% in a weight ratio of 1:2.2, and impregnate for 1.2 hours to obtain a mixture 1;

[0024] 3) Preactivation: Preactivate the mixture 1 obtained in step 2) at 190° C. for 40 minutes to obtain mixture 2;

[0025] 4) Activation: put the mixture 2 obtained in step 3) into the activation furnace, -1 The activation furnace was heated to 410° C. to activate mixture 2 at 410° C. for 50 min to obtain mixture 3; and

[0026] 5) Washing and drying: the mixture 3 obtained in step 4) is cooled to room temperature, and the cooled mixture 3 is washed with water to neutrality, and then the neutral mixture 3 is dried to obtain a black solid that is made of camphor leaves Activated carbon prepared from slag.

Embodiment 3

[0028] 1) crushing: crushing camphor leaf slag into uniform subsections;

[0029] 2) Impregnation: Mix the camphor leaf residue pulverized in step 1) with phosphoric acid with a concentration of 80% in a weight ratio of 1:2.5, and impregnate for 1 hour to obtain a mixture 1;

[0030] 3) Preactivation: Preactivate the mixture 1 obtained in step 2) for 30 minutes at 200° C. to obtain mixture 2;

[0031] 4) Activation: put the mixture 2 obtained in step 3) into the activation furnace, -1 Raising the temperature of the activation furnace to 400° C. to activate mixture 2 at 400° C. for 55 min to obtain mixture 3; and

[0032] 5) Washing and drying: the mixture 3 obtained in step 4) is cooled to room temperature, and the cooled mixture 3 is washed with water to neutrality, and then the neutral mixture 3 is dried to obtain a black solid that is made of camphor leaves Activated carbon prepared from slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com