Assembled membrane bioreactor

A membrane bioreactor, assembled technology, applied in the field of sewage treatment, can solve the problems of inability to adapt to large-scale application needs and ecological construction, long custom manufacturing cycle, non-standard equipment, etc., to facilitate the installation of pipe valves, reduce Small footprint and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

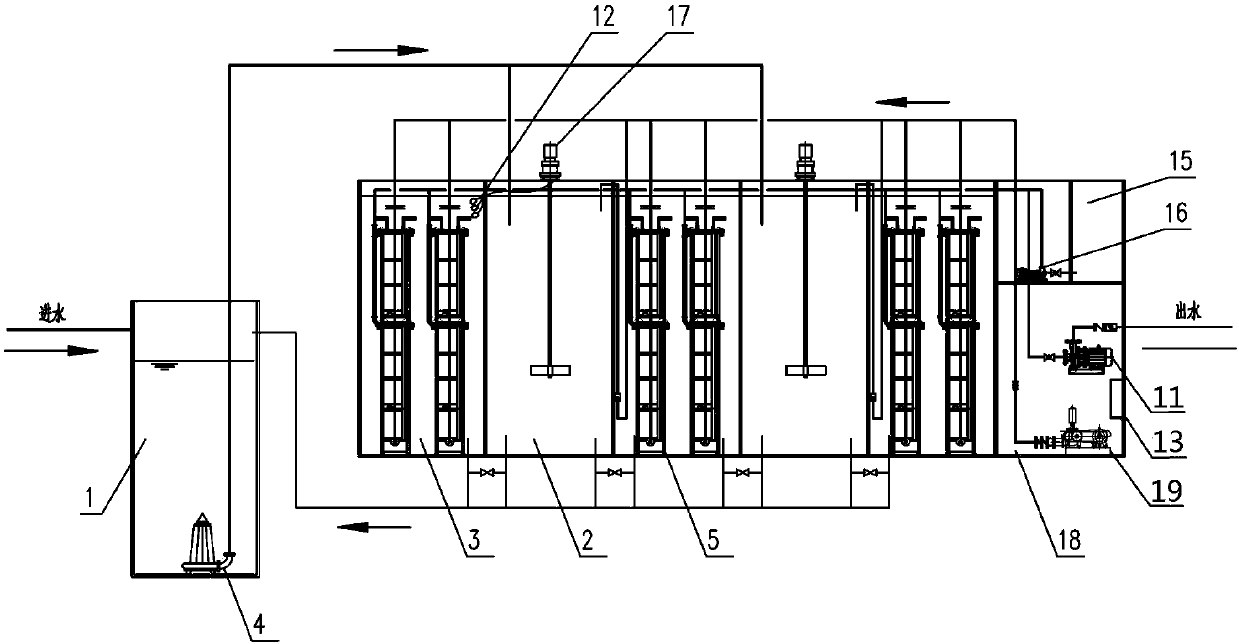

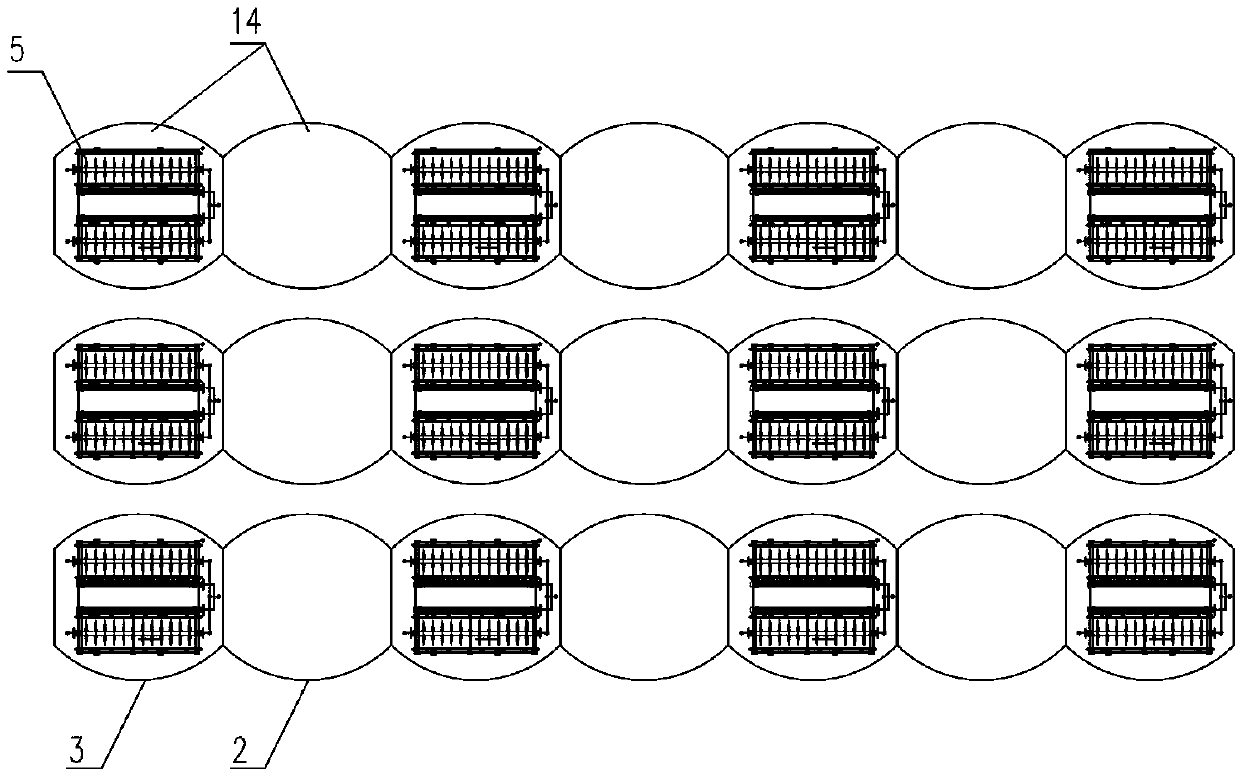

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~4 As shown, the assembled membrane bioreactor of the present invention is spliced by a plurality of functional tanks 14 connected by pipelines. Functional tank 2 and the functional tank 18 as the control room; the size of the functional tank 14 selected in this embodiment is a cylinder of 2.8*2.76*6m (length×width×high), containing 12 aerobic pool function tanks body and 9 anoxic pool functional tanks, which are arranged alternately in a matrix, and can treat domestic sewage or river sewage with a water volume of 5000t / d. Therefore, the prefabricated membrane bioreactor can splice a plurality of functional tanks 14 of required size according to the change of the treated water volume. The functional tanks 14 are connected by pipelines, and the cross-section of each functional tank 14 is symmetrical outward along the axis. Protruding in a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com