Latex paint waste water pre-treating device

A pretreatment device, latex paint technology, applied in water/sewage treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., to improve biodegradability, prevent polarization or scaling, and sewage treatment efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

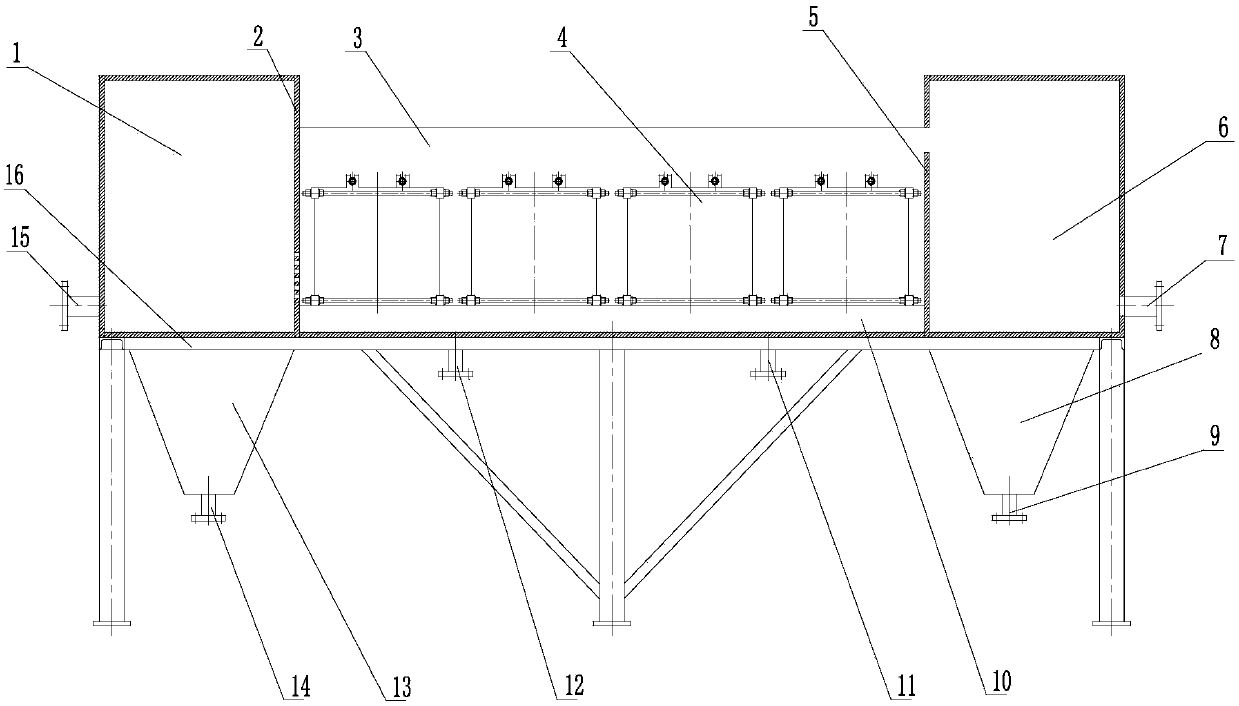

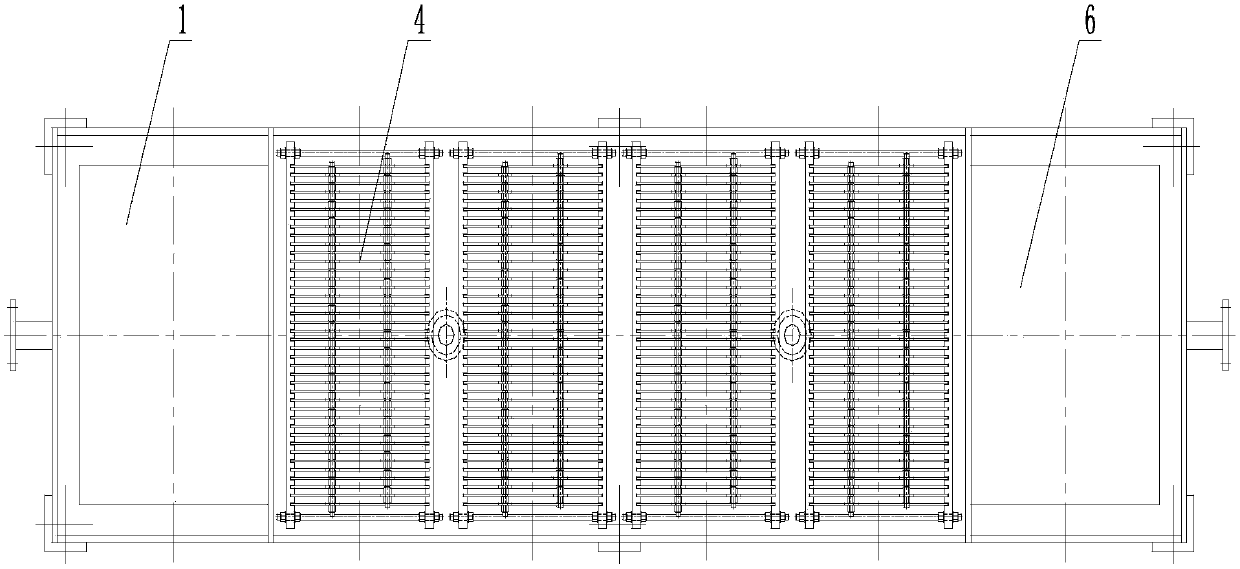

[0027] exist figure 1 , 2 Among them, the latex paint wastewater pretreatment device of the present embodiment consists of a water inlet tank 1, a first dividing plate 2, a flocculation reaction tank 3, an electrocoagulation reactor 4, a second dividing plate 5, a water outlet tank 6, an outlet pipe 7, two Secondary settling tank 8, fourth blowdown pipe 9, electroflocculation reactor base 10, third blowdown pipe 11, second blowdown pipe 12, primary settling tank 13, first blowdown pipe 14, water inlet pipe 15, and support 16 are connected.

[0028] A water inlet tank 1, a flocculation reaction tank 3, and a water outlet tank 6 are sequentially installed on the bracket 16, the water inlet tank 1, the flocculation reaction tank 3 and the water outlet tank 6 are connected as one, and a water inlet pipe 15 is installed on one side of the water inlet tank 1, A first partition 2 is installed between the other side of the water inlet tank 1 and the flocculation reaction tank 3, and ...

Embodiment 2

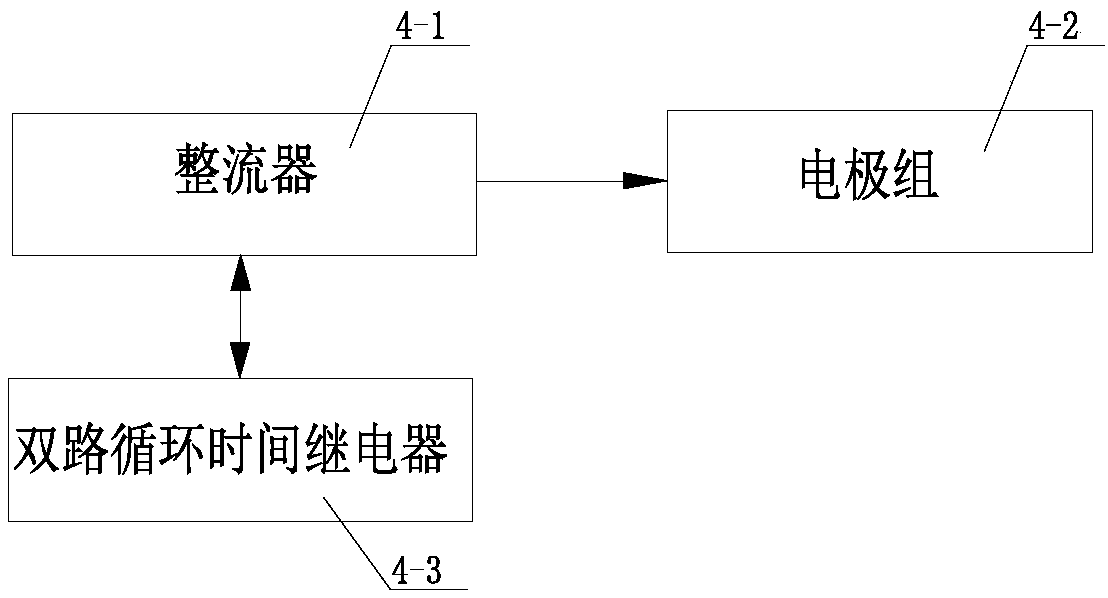

[0034] In this embodiment, the water inlet tank 1, the flocculation reaction tank 3, and the water outlet tank 6 are sequentially installed on the support 16, the water inlet tank 1, the flocculation reaction tank 3 and the water outlet tank 6 are connected as one, and the water inlet tank 1 and the flocculation reaction tank The first partition 2 is installed between the tanks 3, and the middle and lower parts of the first partition are processed with evenly distributed water distribution holes, the aperture of the water distribution holes is 10mm, and the electroflocculation reactor base 10 in the flocculation reaction tank 3 is installed with The electrocoagulation reactor 4, the number of electrode groups 4-2 of the electrocoagulation reactor 4 is 1 group, and the two ends of the electrode group 4-2 are insulated under the framework 4-2-4 with insulating screws 4-2- 4 Fixedly connected to form the base of the electrode plate, the inner sides of the two lower insulating fram...

Embodiment 3

[0036] In this embodiment, the water inlet tank 1, the flocculation reaction tank 3, and the water outlet tank 6 are sequentially installed on the support 16, the water inlet tank 1, the flocculation reaction tank 3 and the water outlet tank 6 are connected as one, and the water inlet tank 1 and the flocculation reaction tank The first partition 2 is installed between the tanks 3, and the middle and lower parts of the first partition are processed with evenly distributed water distribution holes. The aperture of the water distribution holes is 30 mm. The electroflocculation reactor 4, the number of electrode groups 4-2 of the electroflocculation reactor 4 is 5 groups, and the two ends of the electrode group 4-2 are insulated with insulating screws 4-2-4. 4 Fixedly connected to form the base of the electrode plate, the inner sides of the two lower insulating frames 4-2-4 are processed with 20 L-shaped slots at equal intervals along the length direction, the first electrode plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com