A kind of reactive polysiloxane flame retardant coating and preparation method thereof

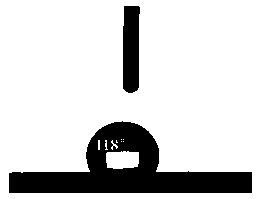

A technology of polysiloxane and flame retardant coating, applied in the field of reactive polysiloxane flame retardant coating and its preparation, can solve the problem of reducing the mechanical properties of the matrix, the uneven composition, and the influence of the flame retardant coating is not mentioned. Coating and wood adhesion and other issues, to achieve the effect of excellent flame retardant performance, good flame retardant performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

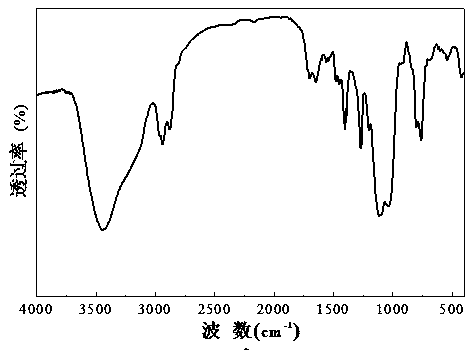

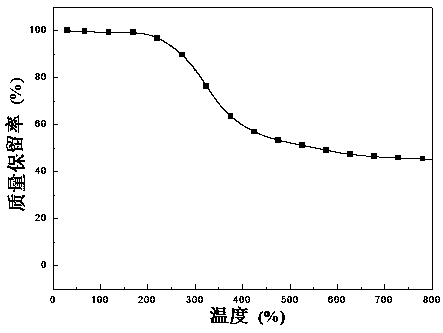

Image

Examples

Embodiment 1

[0078] 5 parts of poly(methyl hydrogen siloxane-dimethyl siloxane copolymer), 6*10 -5 Parts of Karstdet catalyst and 50 parts of isopropanol were added to a four-necked flask equipped with a reflux condenser, a thermometer and magnetic stirring, and an inert atmosphere. The temperature was raised to 70 °C and then stirred at a constant temperature for 15 min; after the temperature was raised to 100 °C, the constant temperature 15 parts of isocyanatopropyl triethoxysilane and 15 parts of isopropanol in the pressure funnel were added dropwise to the four-necked flask, and the constant temperature reaction was continued for 6 hours; 35 parts of allyl in the constant pressure funnel were added within 2 hours. Glycidyl ether and 20 parts of isopropanol were added dropwise to the four-necked flask, and the constant temperature reaction was continued for 6 hours; the solvent and unreacted substances were removed by distillation under reduced pressure to obtain the flame retardant inte...

Embodiment 2

[0091] 10 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 4*10 -5 Parts of Speier's catalyst and 60 parts of toluene solvent were added to a four-necked flask equipped with a reflux condenser, a thermometer and magnetic stirring, and an inert atmosphere, and the temperature was raised to 70 °C, followed by constant temperature stirring for 10 min; 10 parts of isocyanatopropyl triethoxysilane and 15 parts of toluene in the funnel were added dropwise to the four-necked flask, and the constant temperature reaction was continued for 8h; 30 parts of allyl glycidyl ether in the constant pressure funnel were added within 2h. Add 35 parts of toluene dropwise into the four-necked flask, and continue to react at constant temperature for 7 hours; remove the solvent and unreacted substances by vacuum distillation to obtain the flame retardant intermediate API; put all the flame retardant intermediates obtained in the previous step API, 35 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene...

Embodiment 3

[0095] Mix 6 parts of polymethyl hydrogen siloxane, 7*10 -5 Parts of Speier's catalyst and 70 parts of toluene solvent were added to a four-necked flask equipped with a reflux condenser, a thermometer and magnetic stirring, and an inert atmosphere. The temperature was raised to 70 °C and then stirred at a constant temperature for 10 min; after the temperature was raised to 100 °C, the 10 parts of 3-isocyanatopropyltrimethoxysilane and 15 parts of toluene in the funnel were added dropwise to the four-necked flask, and the constant temperature reaction was continued for 7 hours; 50 parts of allyl glycidyl ether in the constant pressure funnel were added within 3 hours. Add 20 parts of toluene into the four-necked flask dropwise, and continue to react at constant temperature for 5 hours; remove the solvent and unreacted substances by vacuum distillation to obtain the flame retardant intermediate API; all the flame retardant intermediate API obtained in the previous step , 30 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com