Porous anti-reflection film composed of nano-silica hollow particles and preparation method thereof

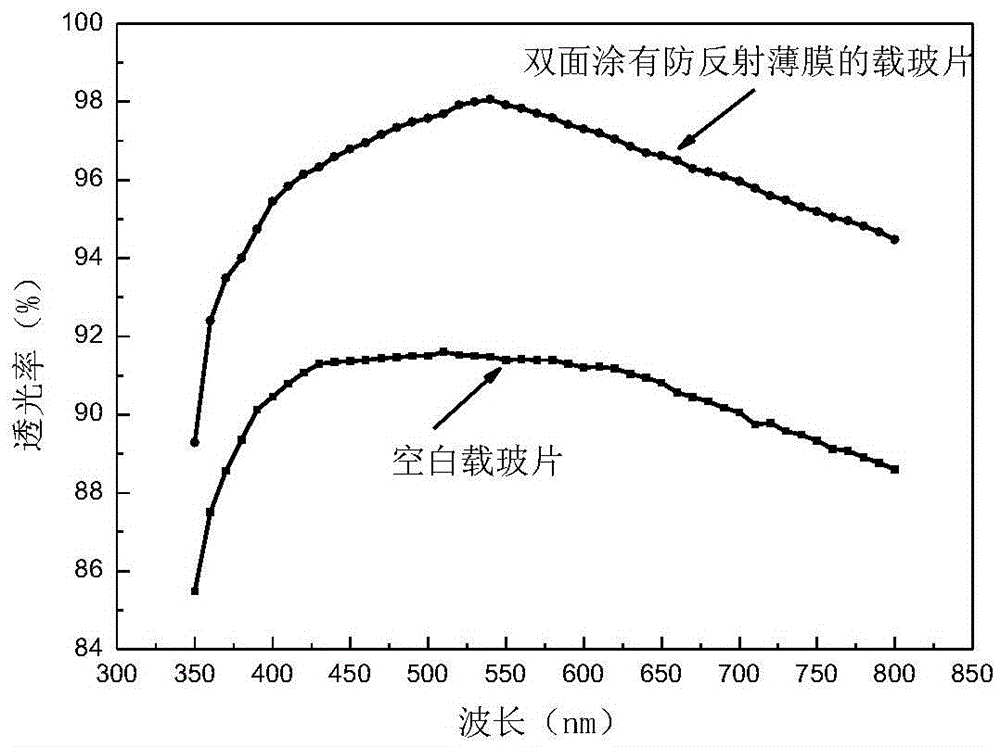

A nano-silica, anti-reflection technology, applied in the field of porous anti-reflection film and its preparation, can solve the problems of poor mechanical properties, and achieve the effect of overcoming poor mechanical properties, high mechanical strength and scrub resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The preparation method of nano-silica hollow particles is as follows:

[0038] Weigh 0.8g of polyacrylic acid aqueous solution with a mass fraction of 30%, dissolve it in 4ml of ammonia water with a mass fraction of 28%, and add 140mL of absolute ethanol to mix. After stirring evenly, drop it with a pipette every 1 hour Add 1ml of tetraethyl orthosilicate, add dropwise 3 times in total, after the dropwise addition, continue to stir for 12 hours, and obtain nanoparticles with polyacrylic acid as the core and silicon dioxide as the shell after suction filtration. Finally, the obtained nanoparticles are centrifuged and washed four times successively with absolute ethanol and deionized water to remove the polyacrylic acid in the core part of the nanoparticles, so as to obtain the nano-silica hollow particles.

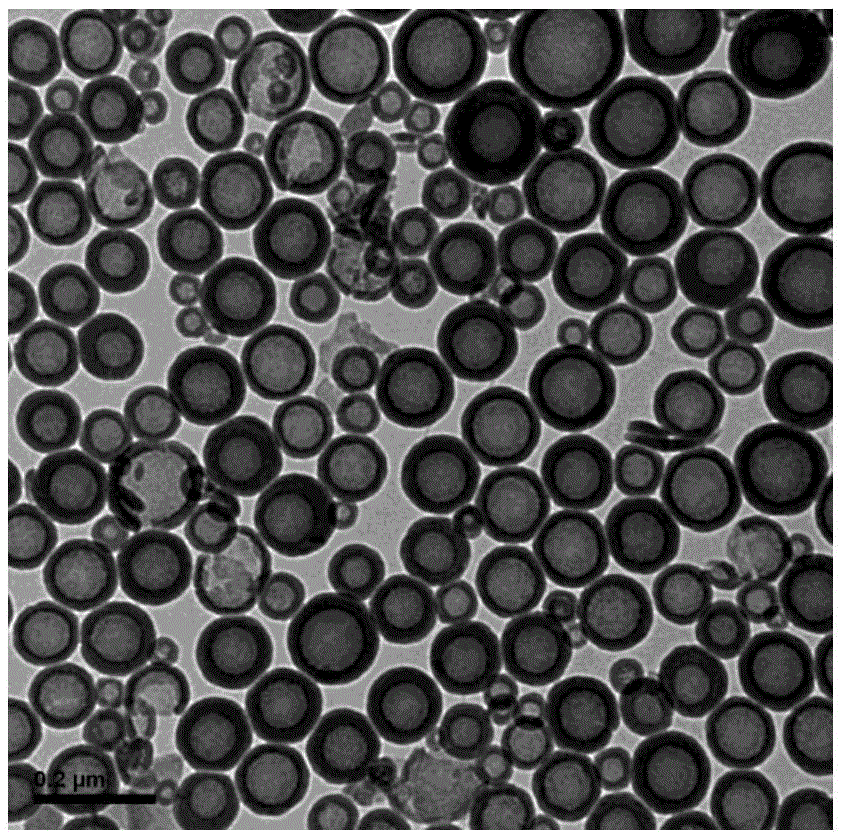

[0039] Observing the morphology of the obtained nano silicon dioxide hollow particles by transmission electron microscope, the results are as follows figure 1 s...

Embodiment 2

[0048] Weigh 0.4g of polyacrylic acid aqueous solution with a mass fraction of 30%, dissolve it in 4ml of ammonia water with a mass fraction of 28%, and add 140ml of absolute ethanol for mixing. After stirring evenly, drop it with a pipette every 1 hour Add 0.5ml of tetraethyl orthosilicate, add dropwise 3 times in total, after dropwise addition, continue to stir for 12 hours and then filter with suction to obtain nanoparticles with polyacrylic acid as the core and silicon dioxide as the shell. Finally, the obtained nanoparticles are centrifuged and washed four times successively with absolute ethanol and deionized water to remove the polyacrylic acid in the core part of the nanoparticles, so as to obtain the nano-silica hollow particles.

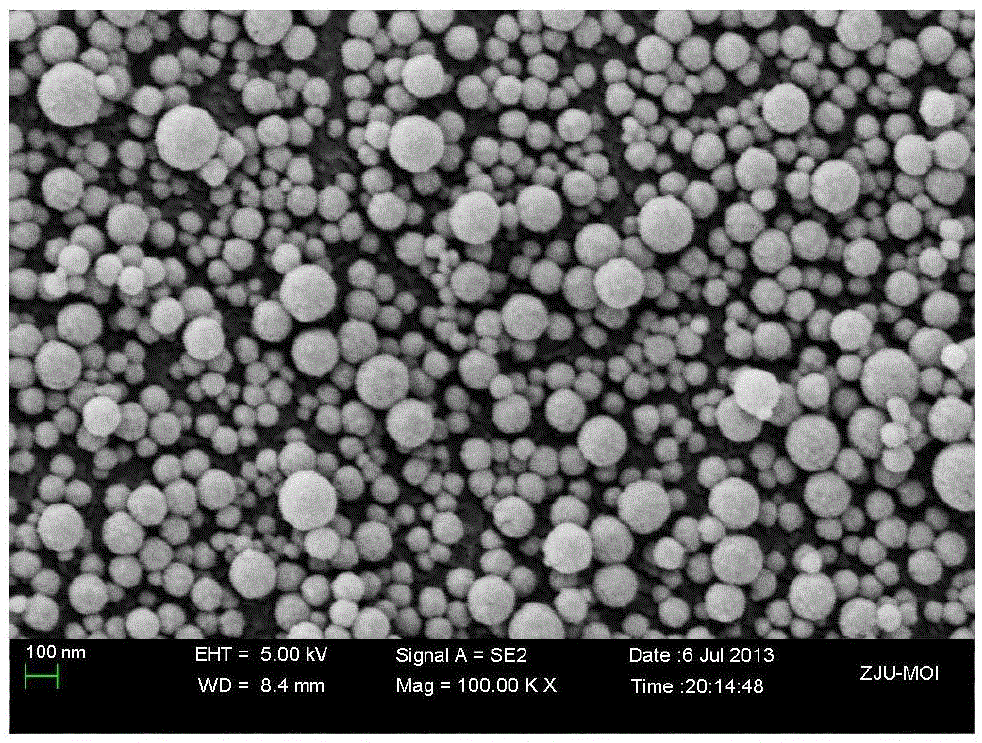

[0049] According to the statistical results of the particle diameters in the transmission electron microscope pictures, the average diameter of the prepared nano-silica hollow particles is 73nm, and the cavity volume fraction is 0.43.

Embodiment 3

[0051] Weigh 0.6g of polyacrylic acid aqueous solution with a mass fraction of 30%, dissolve it in 4ml of ammonia water with a mass fraction of 28% to fully dissolve, add 140ml of absolute ethanol to mix, stir well and drop it with a pipette every 1 hour Add 0.75ml of tetraethyl orthosilicate, add dropwise 3 times in total, after dropwise addition, continue to stir for 12 hours and then filter with suction to obtain nanoparticles with polyacrylic acid as the core and silicon dioxide as the shell. Finally, the obtained nanoparticles are centrifuged and washed four times successively with absolute ethanol and deionized water to remove the polyacrylic acid in the core part of the nanoparticles, so as to obtain the nano-silica hollow particles. According to the statistical results of the particle diameters in the transmission electron microscope pictures, the average diameter of the prepared nano-silica hollow particles is 87nm, and the cavity volume fraction is 0.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com