Organic-inorganic composite flocculant and its preparing process

A production method and composite technology, applied in separation methods, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high moisture content of waste residue, more scum generation, and large volume of sewage liquid, etc. The production process is simple, the production cycle is short, and the reaction is mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The raw material of this embodiment and formula (mass fraction) thereof:

[0055] Aluminum Sulfate 10%

[0057] Dicyandiamide 5%

[0058] Formaldehyde 5%

[0059] water balance

[0060] Process steps and process parameters of the present embodiment:

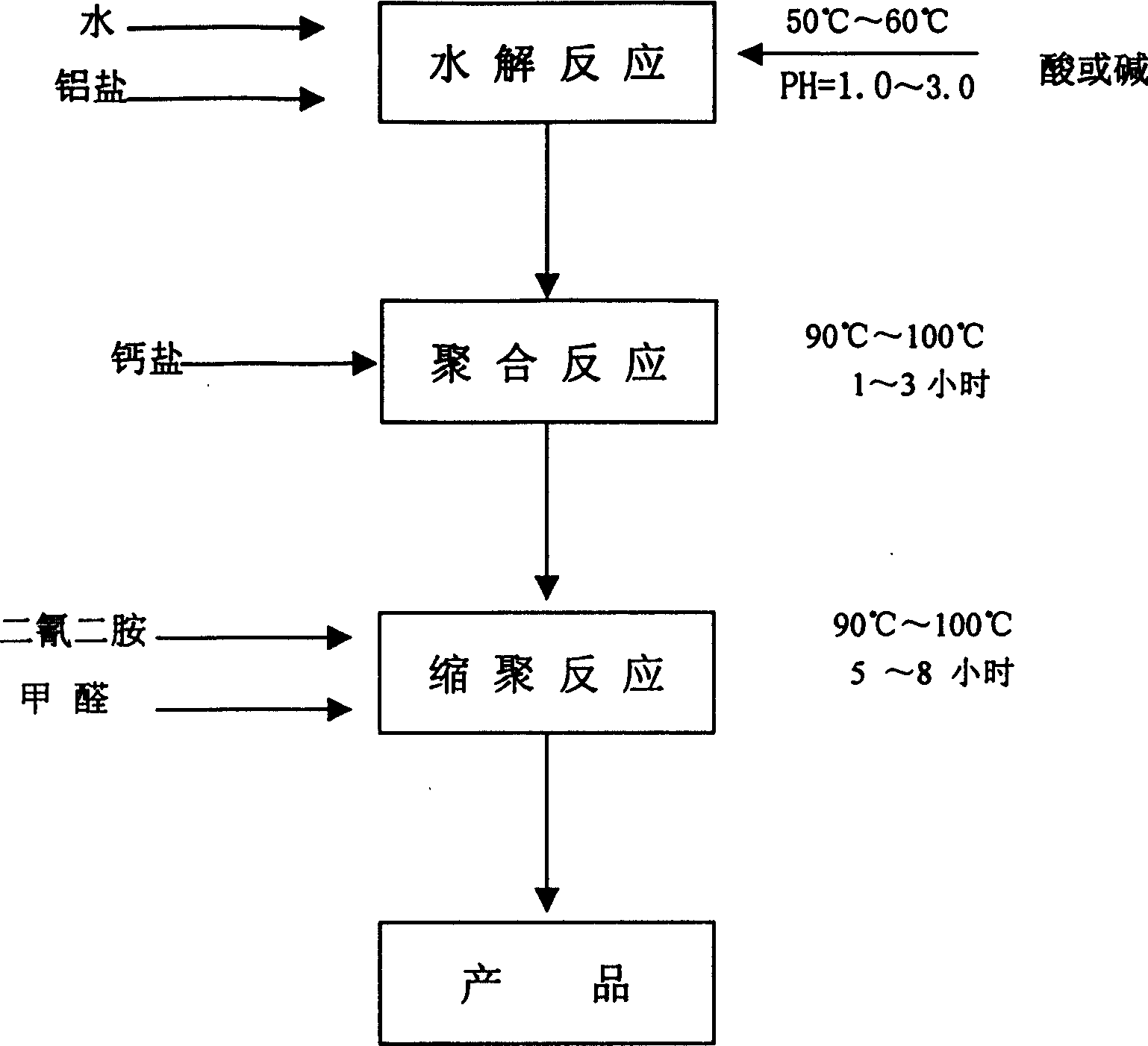

[0061] The processing steps and sequence of the present embodiment are as figure 1 As shown, each process step is carried out under normal pressure.

[0062] (1) Hydrolysis reaction

[0063] Add the required water into the reaction kettle, the water temperature is controlled at 60°C, and then add aluminum sulfate under stirring. When the aluminum sulfate is dissolved, test the pH value of the solution, and adjust the pH value to 2.5 with hydrochloric acid or sodium hydroxide.

[0064] (2) Polymerization reaction

[0065] Calcium chloride is added to the above hydrolyzate under stirring, then the temperature is raised to 95° C. and water glass with a mass fraction of 1.0% is added to pr...

Embodiment 2

[0069] The raw material of this embodiment and formula (mass fraction) thereof:

[0070] Aluminum Chloride 20%

[0071] Dicyandiamide 10%

[0072] Formaldehyde 10%

[0073] water balance

[0074] Process steps and process parameters of the present embodiment:

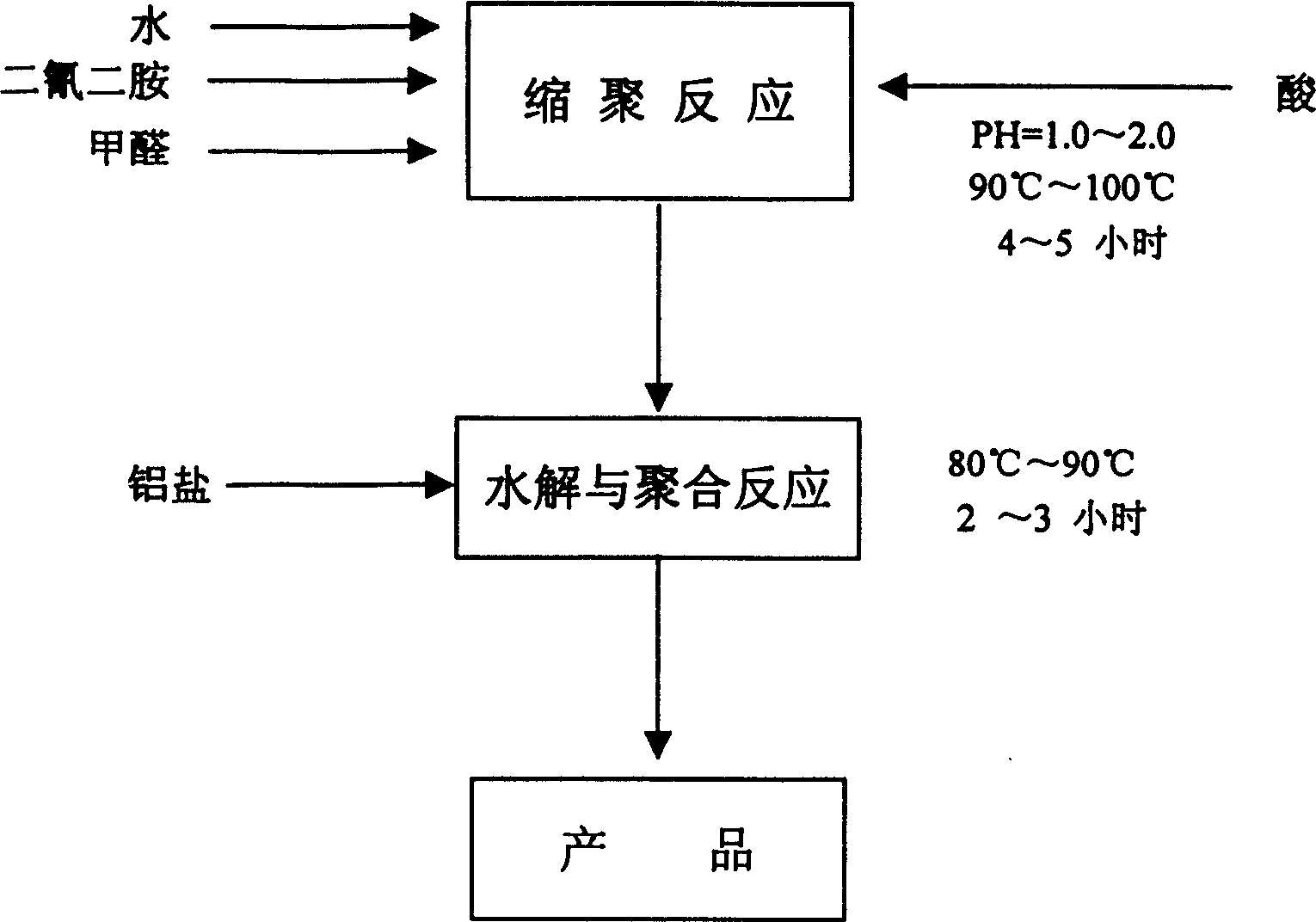

[0075] The processing steps and sequence of the present embodiment are as figure 2 As shown, each process step is carried out under normal pressure.

[0076] (1) Polycondensation reaction

[0077] Add the required water into the reaction kettle, control the water temperature at 100°C, add formic acid to adjust the pH value of the water to 1.5, then add dicyandiamide under stirring, add formaldehyde after it is dissolved, and keep it warm at 100°C for 4 hours. Complete the polycondensation reaction.

[0078] (2) Hydrolysis and polymerization reaction

[0079] Add aluminum chloride to the solution obtained by the polycondensation reaction under stirring, then lower the temperature of the solution to 80°C and keep...

Embodiment 3

[0081] The raw material of this embodiment and formula (mass fraction) thereof:

[0082] Aluminum Chloride 15%

[0083] Dicyandiamide 8%

[0084] Formaldehyde 10%

[0085] water balance

[0086] Process steps and process parameters of the present embodiment:

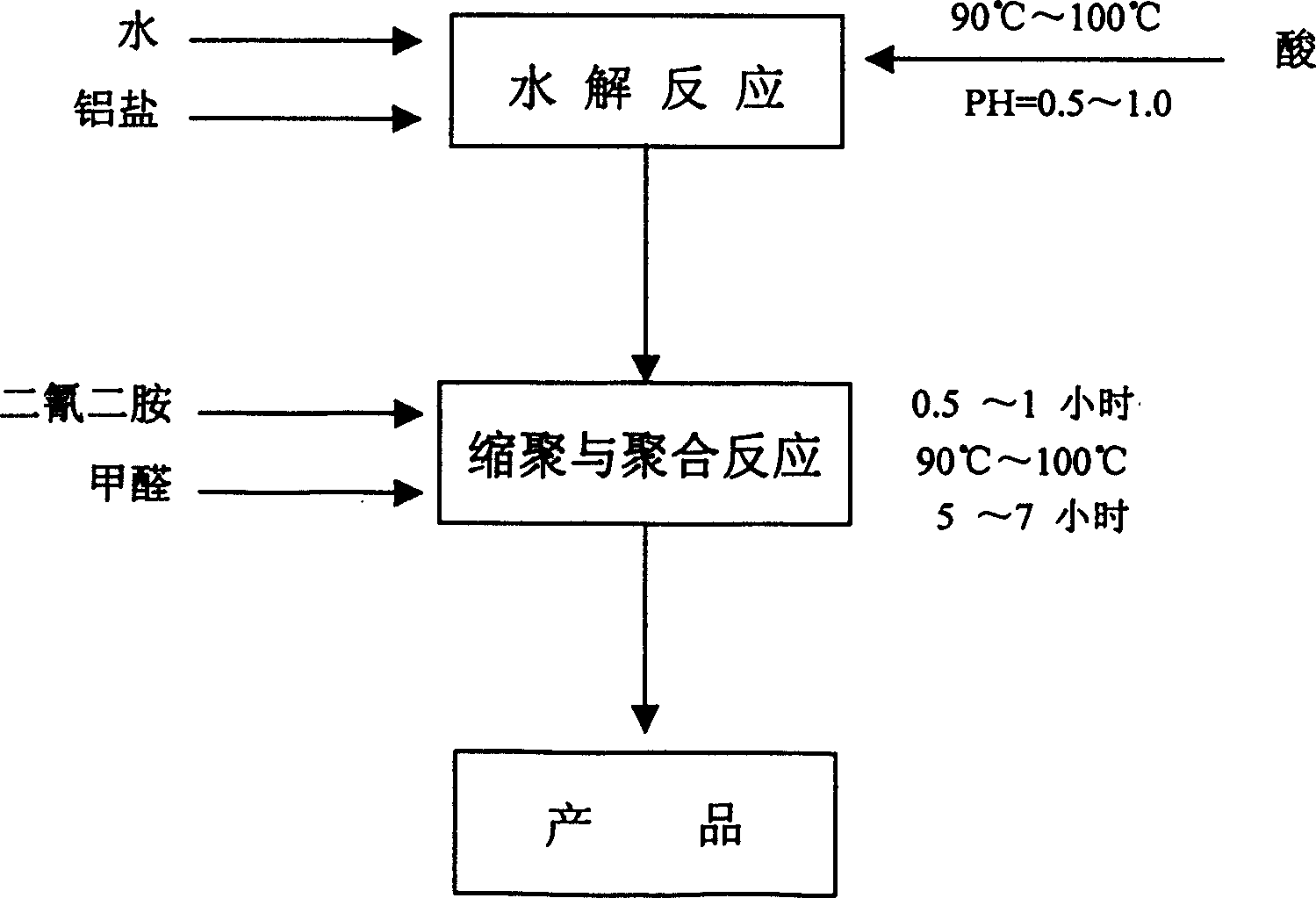

[0087] The processing steps and sequence of the present embodiment are as image 3 As shown, each process step is carried out under normal pressure.

[0088] (1) Hydrolysis reaction

[0089] Add the required water into the reaction kettle, control the water temperature at 90°C, add industrial concentrated sulfuric acid to adjust the pH value of the water to 1.0, then add aluminum chloride under stirring, and the hydrolysis solution will be obtained after the aluminum chloride dissolves.

[0090] (2) Polycondensation and polymerization reaction

[0091] Add dicyandiamide to the above hydrolysis solution under stirring, add formaldehyde at 1 hour of the dissolution reaction, and keep the reaction at 90°C for 7 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com