Method for extracting fulvic acid through low-temperature carbonization

A technology of fulvic acid and low temperature, which is applied in special forms of dry distillation, organic chemistry, coke oven, etc., can solve the problems of low extraction rate and large residue discharge, and achieve the effect of improving extraction rate and less corrosive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for extracting fulvic acid by low-temperature dry distillation comprises the following steps:

[0027] (1) Low-temperature dry distillation: break the weathered coal into particles no larger than 0.5mm, then place it in a closed container isolated from air, and conduct low-temperature dry distillation at 500°C-650°C for 30 minutes to 40 minutes to collect coal tar;

[0028] (2) Alkaline extraction: Coal tar is mixed with weak alkaline solution, the pH of the mixed solution is adjusted to 6.0-8.0 to obtain an alkaline extraction solution, and CuCl is added to the alkaline extraction solution 2 powder, CuCl 2 The mass ratio of powder to coal tar is 0.03:1; stir the alkali extraction solution for 0.5-1h, centrifuge and discard the precipitate to obtain the alkali extraction supernatant;

[0029] (3) acid extraction: use 0.5MHNO 3 The solution adjusts the pH of the alkali-extracted supernatant to 1.0-2.0 to obtain an acid extract, and adds MnO to the acid extra...

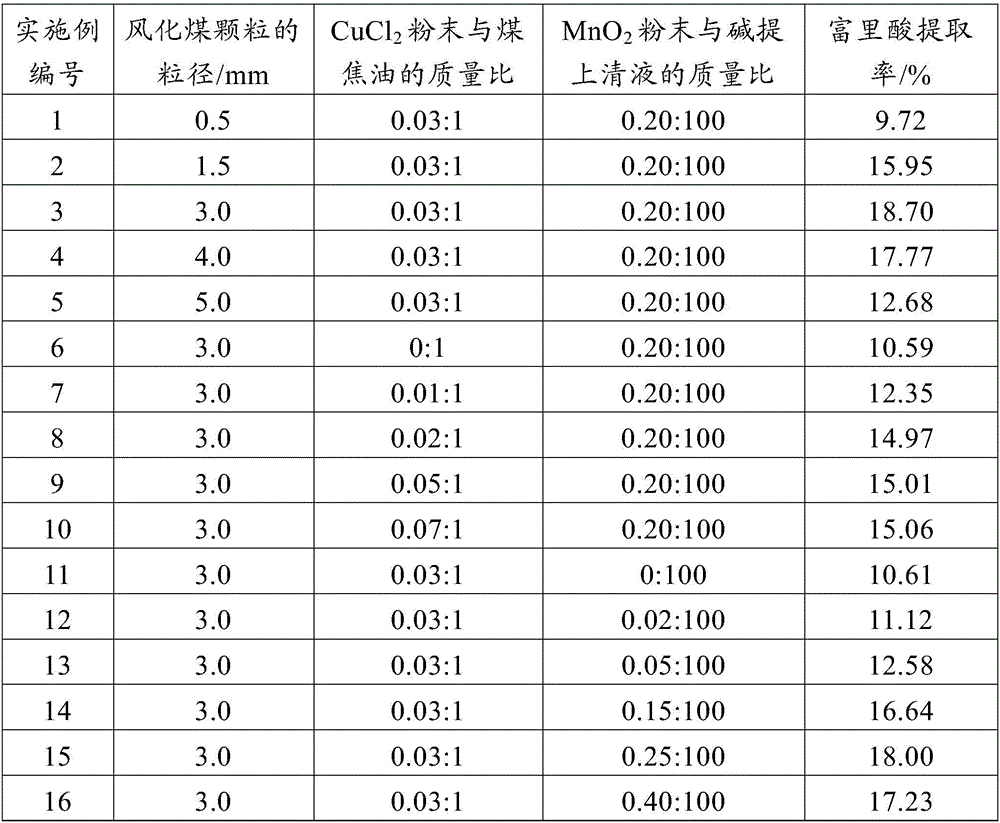

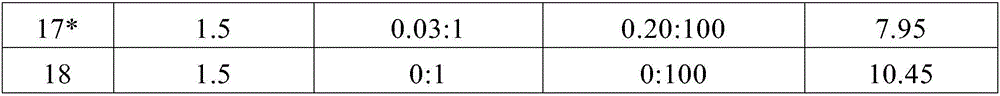

Embodiment 2-18

[0034] Except for the contents shown in Table 1 below, it was carried out in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com