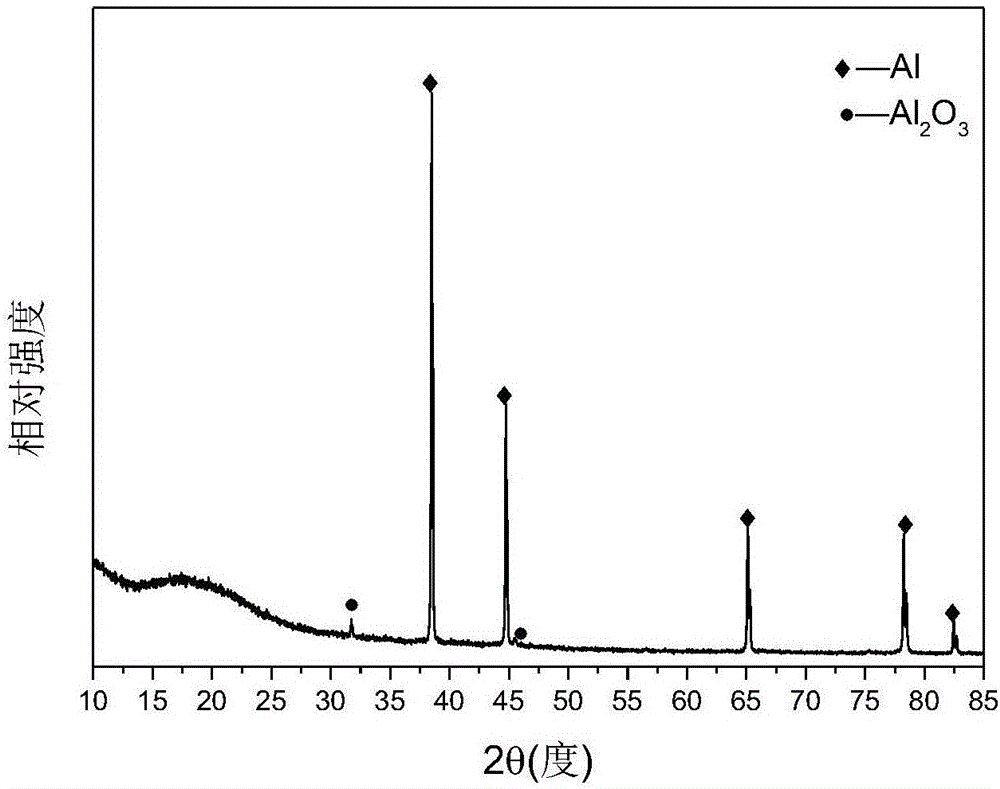

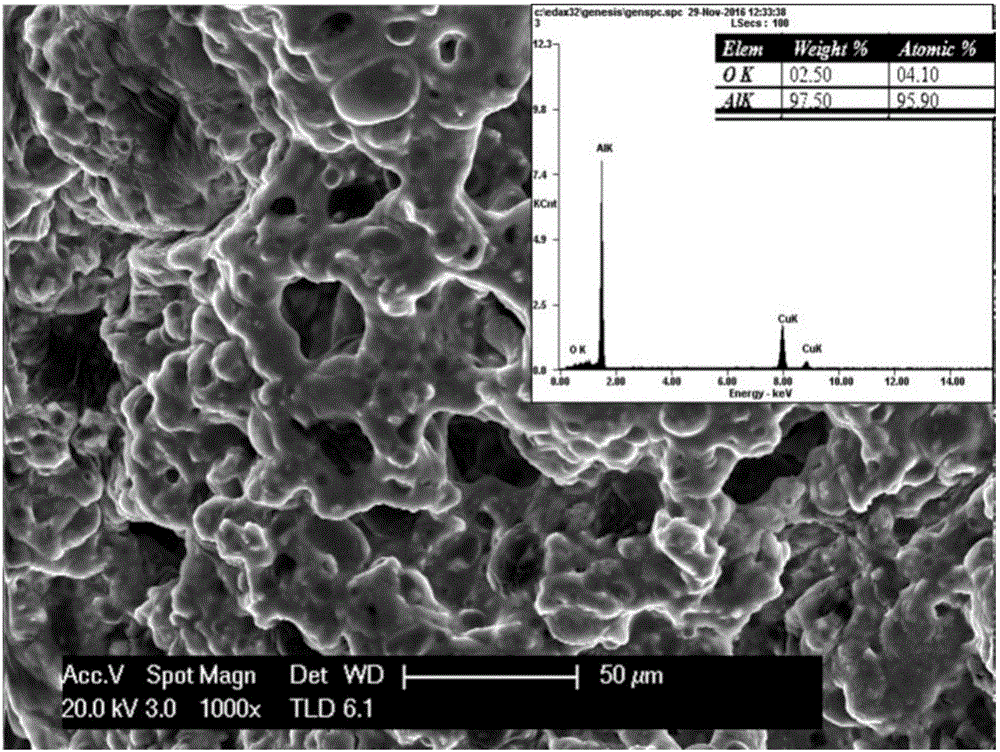

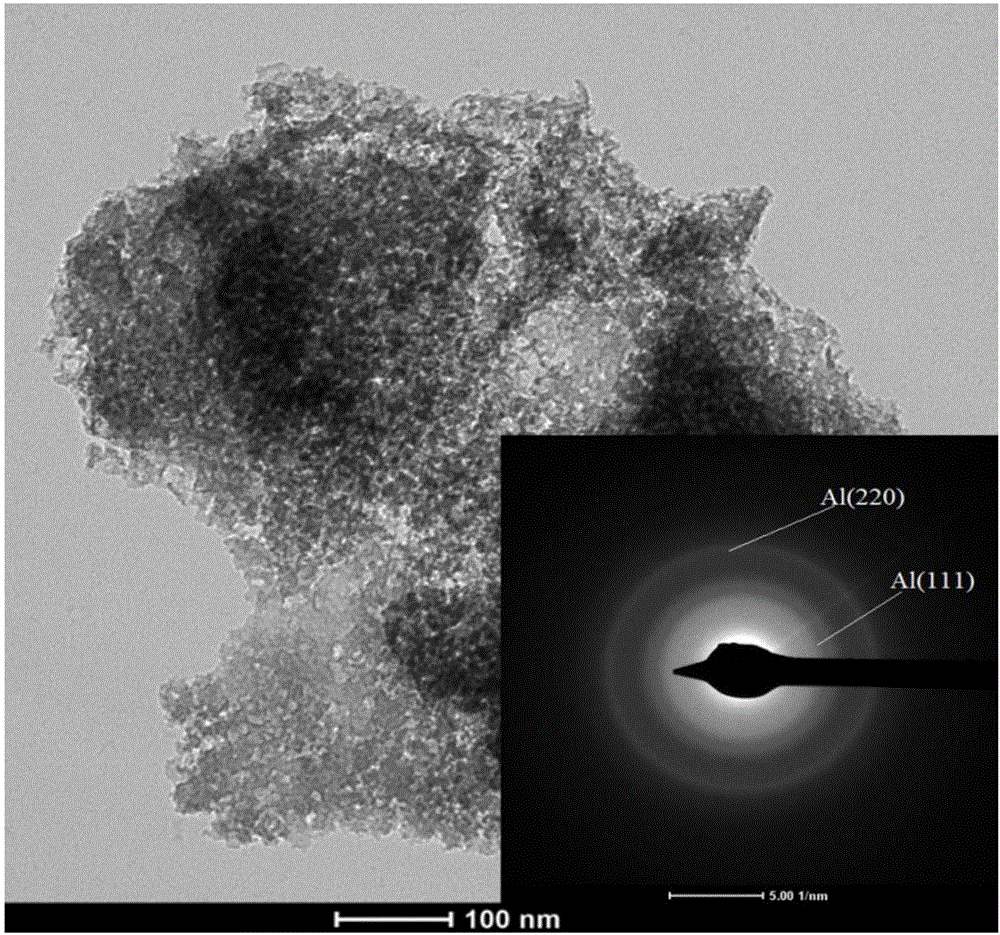

Aluminium mesoporous material and preparation method thereof

An aluminum mesoporous and raw material technology, which is applied in the field of mesoporous materials to achieve the effects of high porosity, high purity, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation steps of an aluminum mesoporous material are as follows:

[0030] (1) Weigh NaAlH with a purity of 98% under the protection of an argon atmosphere with a concentration of 99.9999% 4 The powder is pressed and formed by a tableting device, the pressure used during pressing is 11-13 MPa, and the holding time is 10 minutes. Then place the formed sheet material in an alumina crucible, and coat a layer of copper foil on the outer layer of the alumina crucible, and leave holes on the copper foil to facilitate the control of the gap between the copper foil and the crucible in the subsequent process. Pores to control air flow sweep and output.

[0031] (2) Place the sample processed in step (1) in a tube furnace, wash it with argon three times, adjust the argon intake airflow, and at the same time use a mechanical pump to vacuumize to achieve dynamic balance and keep the negative pressure in the tube stable. Set the temperature to roast the sample. During the r...

Embodiment 2

[0042] Adjust the argon flow of the sample during the roasting process in step (2), and set it to 60sccm, 90sccm, and 100sccm respectively, and the rest of the steps are the same as in Example 1 to investigate the impact of different flow rates on the final obtained material.

[0043] The experimental results show that when the intake flow rate was low (60sccm), the sample purity decreased, and when the intake flow rate was 90sccm, the sample purity was high, and the refinement showed that it reached 98%, and when the intake flow rate was increased to 100sccm, the result and 90sccm is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com