Wear-resistant aluminum alloy and preparation method thereof

A technology of aluminum alloy and master alloy, applied in the field of aluminum alloy and its preparation, can solve the problems of complex forming process, high cost, unfavorable production, etc., and achieve the effect of simple forming process, increased hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

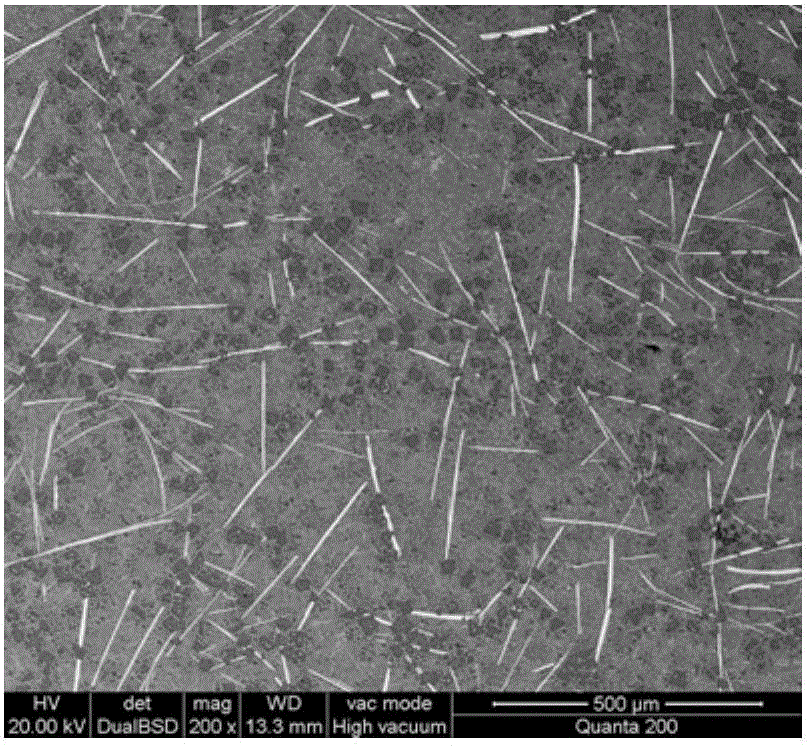

[0038] Example 1 Preparation of Al-10Si-10Mg-1.3Fe-0.3Mn-0.7Cr-0.05Sr alloy by ordinary casting method

[0039] The raw materials used in this embodiment include Fe-rich secondary aluminum alloy, pure aluminum, pure Mg, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr master alloy. The forming method is as follows: first by weight percentage: Si: 10%, Mg: 10%, Fe: 1.3%, Mn: 0.3%, Sr: 0.7%, Sr: 0.05%, and the balance is Al. Among them, Fe is blended with Fe-rich recycled A356 aluminum alloy, and the insufficient Al is blended with pure aluminum. Melt Fe-rich recycled A356 aluminum alloy, pure aluminum, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr alloy at 740℃, and then add the weighed alloy to the melt when it is melted to a semi-solid state Pure Mg, after all is melted, stir manually to make the composition uniform, heat up to 770°C, and keep it for 10 minutes. Use 2# refining agent for refining, let it stand for 5 minutes, keep the temperature of the molten metal at 770℃, remove the slag and pour it...

Embodiment 2

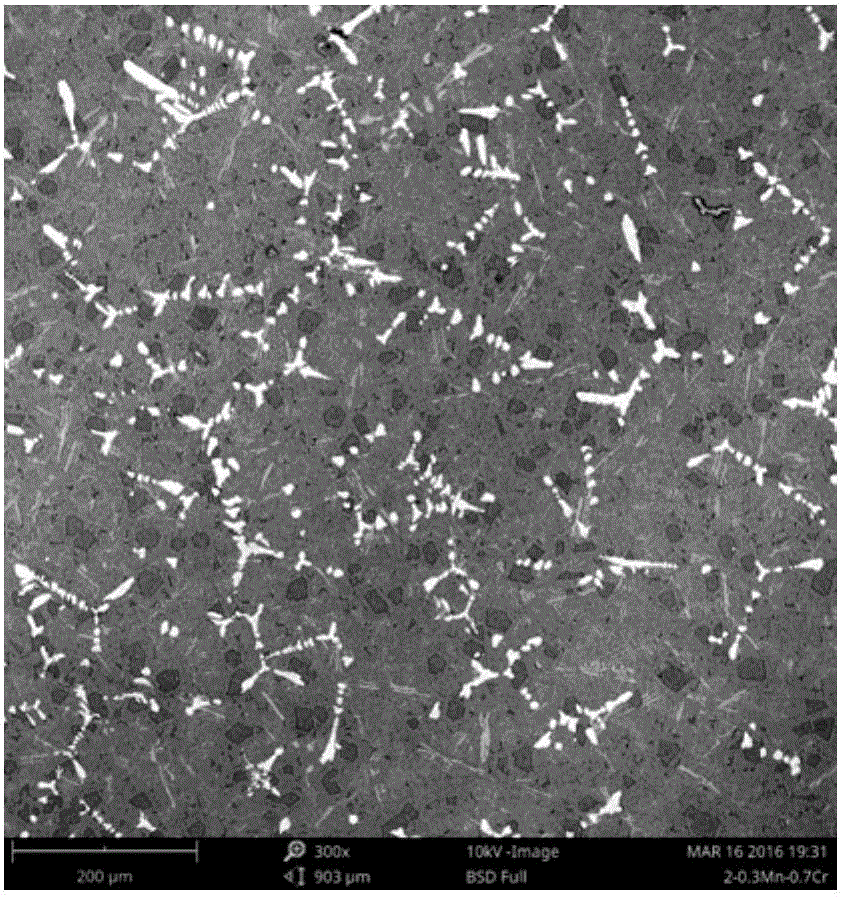

[0042] Example 2 Preparation of Al-12Si-12Mg-0.8Fe-0.7Mn-0.3Cr-0.1Sr alloy by vibration casting method

[0043] The raw materials used in this embodiment include Fe-rich secondary aluminum alloy, pure aluminum, pure Mg, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr master alloy. The forming method is as follows: first by weight percentage: Si: 12%, Mg: 12%, Fe: 0.8%, Mn: 0.7%, Cr: 0.3%, Sr: 0.1%, and the balance is Al. Among them, Fe is prepared by using Fe-rich recycled A356 aluminum alloy, and the insufficient Al amount is prepared by using pure aluminum. Melt Fe-rich recycled A356 aluminum alloy, pure aluminum, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr alloy at 760℃, and then add tin foil to the melt when it is melted to a semi-solid state. After the weighed pure Mg is completely melted, manually stir to make the composition uniform, heat up to 780°C, and keep it for 10 minutes. Refine with 2# refining agent, let stand for 5 minutes, keep the temperature of the molten metal at 780℃, remove th...

Embodiment 3

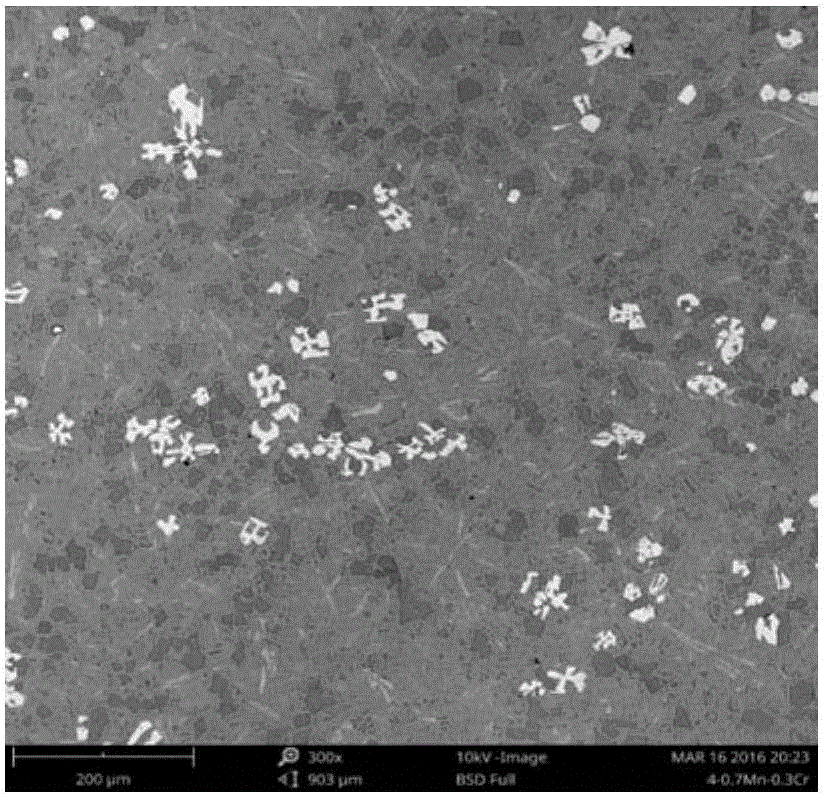

[0046] Example 3 Preparation of Al-12Si-10Mg-1.6Fe-0.5Mn-0.5Cr-0.1Sr alloy by vibration casting method

[0047] The raw materials used in this embodiment include Fe-rich secondary aluminum alloy, pure aluminum, pure Mg, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr master alloy. The forming method is as follows: first by weight percentage: Si: 12%, Mg: 10%, Fe: 1.6%, Mn: 0.5%, Cr: 0.5%, Sr: 0.1%. Among them, Fe is prepared by using Fe-rich recycled A356 aluminum alloy, and the insufficient Al amount is prepared by using pure aluminum. Melt Fe-rich recycled A356 aluminum alloy, pure aluminum, Al-20Si, Al-10Cr, Al-10Mn, Al-10Sr alloy at 750℃, and then add tin foil to the melt when melted to a semi-solid state. After the weighed pure Mg is completely melted, it is manually stirred to make the composition uniform, and the temperature is raised to 775°C and the temperature is kept for 10 minutes. Refine with 2# refining agent, let stand for 5 minutes, keep the temperature of the molten metal a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com