LED lamp tube flexible automatic production line

A technology of LED lamp tubes and automatic production lines, applied in lighting and heating equipment, light sources, lighting devices, etc., can solve the problems of low production line efficiency, high wage costs, large consumption of manpower and material resources, etc., and achieve the effect of improving welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

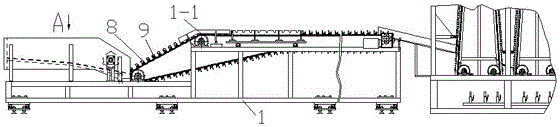

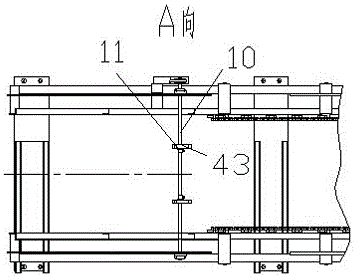

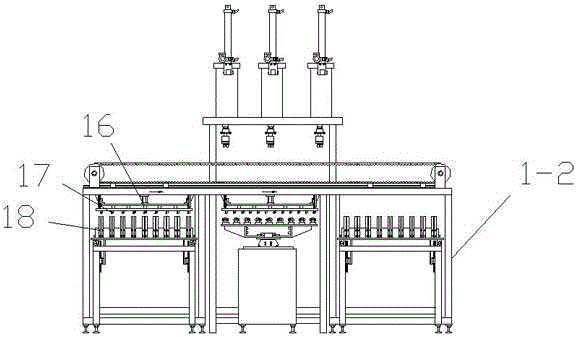

[0050] A flexible automatic production line for LED lamp tubes, including a transmission and curing mechanism 1 for loading and pasting light strips on glass tubes, and a dehumidifier 2 is installed next to the transmission and curing mechanism 1 for loading and pasting light strips on glass tubes, and pretreats the lamp tubes through down-tube transmission The parts are transported to the dehumidifier 2, and the lamp tube pretreatment parts processed by the dehumidifier 2 are transported to the soldering system 3 through the down tube transmission, and then transferred to the wiper plug and loaded into the detection and rejection mechanism 4 through the soldering system 3 In the middle, the lamp tube pretreatment parts processed by the detection and rejection mechanism 4 are transported by the lower tube to the rubber drying machine 5, and then enter the pressing needle labeling structure 6 after being processed by the rubber drying machine 5. The processing of the pressing ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com