Precisely-controllable gas supply system

An air supply system, precise technology, applied in control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problem of inability to provide accurately controllable temperature, humidity and flow gas, and achieve the gas path structure Simple, precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

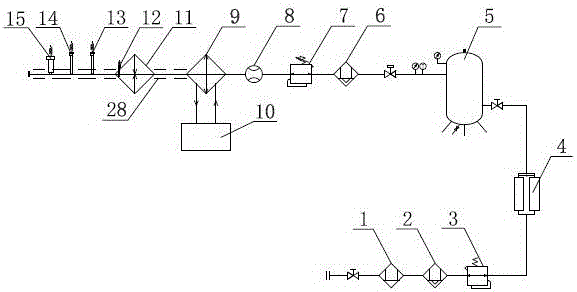

[0025] Such as figure 1 As shown, the precise and controllable air supply system of the present invention includes a drying module, a flow control module, a temperature control module, and a detection module connected in series in sequence. The inlet end of the coarse-efficiency filter 1 of the drying module is connected to an external air source, and the outlet end is connected to the fine-efficiency filter 2, and then connected to the athermal adsorption dryer 4 through a manual pressure reducing valve 3, and the dried gas enters Gas storage tank 5. The gas outlet end of the gas storage tank 5 is connected to the mass flow controller 8 through the precision filter 6 and the electric proportional valve 7 of the flow control module. The air outlet of the mass flow controller 8 is connected to the refrigeration evaporator 9 and the heater 11 of the temperature control module in sequence. The refrigeration evaporator 9 is also connected to the refrigeration system 10, and an over...

Embodiment 2

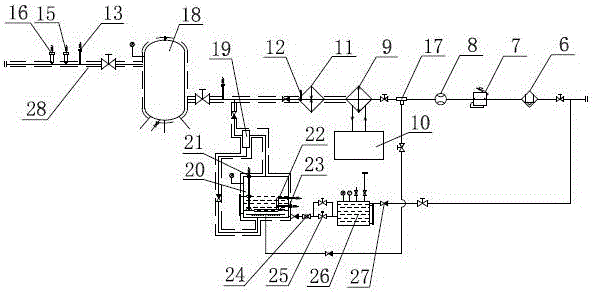

[0028] Such as figure 2 As shown, the precise and controllable gas supply system of the present invention uses the three-way split valve 17 after the flow control module to divide the gas into two paths after passing through the temperature control module and the humidity control module respectively, and then merge into one gas and flow through the detection module. , The output flow, temperature and humidity are all precisely controllable gas. The drying module in this embodiment is the same as the drying module in the first embodiment. It consists of a coarse-effect filter 1, a fine-effect filter 2, a manual pressure reducing valve 3, a thermal adsorption dryer 4, and a gas storage tank in series. 5 composition (not shown in the figure). The outlet end of the air storage tank 5 is connected to a flow control module all the way, including a precision filter 6, an electric proportional valve 7 and a mass flow controller 8 connected in sequence; the other way is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com