Heat conduction plate and its preparation method and battery pack device

A heat conduction plate and heat conduction layer technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as low structural strength, increase process difficulty, and reduce product qualification rate, so as to improve structural strength, ensure heat conduction effect, improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

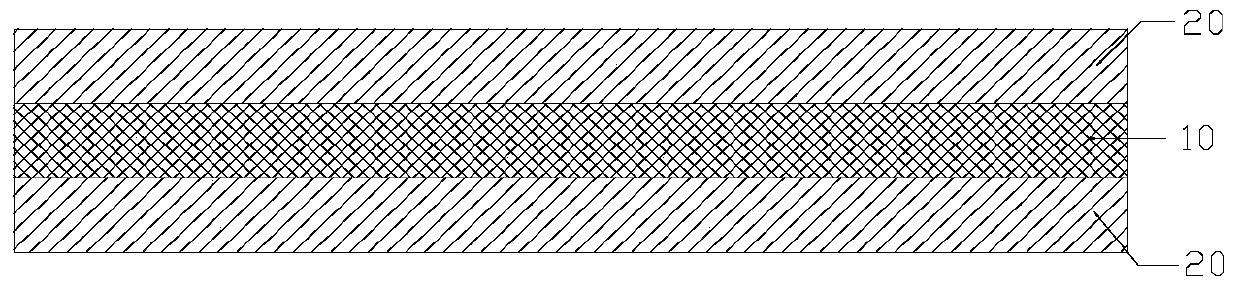

[0038] In a relatively specific embodiment, the preparation method includes the following steps: separately configuring the first resin composition and the second resin composition; respectively putting the first resin composition and the second resin composition into the co-extrusion equipment In different feed chambers, a heat conduction plate comprising a hard heat conduction layer 10 and flexible heat conduction layers 20 located on both sides of the hard heat conduction layer 10 is formed by co-extrusion.

[0039] The preparation method of the heat conduction plate provided by the present invention has simple flow, easy operation and is suitable for large-scale production. Moreover, the heat conduction plate formed by this preparation method also includes a hard heat conduction layer in the middle and flexible heat conduction layers on both sides, and the hard heat conduction layer is used to support the entire heat conduction plate to improve the structural strength of th...

Embodiment 1

[0044] The first resin composition comprises: 100 parts of polyphenylene ether (commercially purchased from the product of Japan Asahi Kasei Co., Ltd. model S201A); Al 2 o 3 (particle size is 40μm) 50 parts; antioxidant 168 (commercially purchased from Shanghai Jinhai Yabao Fine Chemical Co., Ltd.) 3 parts, TAF (commercially purchased from Suzhou Xingtai Photochemical Auxiliary Co., Ltd.) 1 part; silane coupling agent (commercially purchased from Shin-Etsu Corporation, Japan, the brand is KBM-903 product) 1 part; maleic anhydride grafted compatibilizer (commercially purchased from Nanjing Plastic Tai Polymer Technology Co., Ltd., the brand is the product of ST-1) 1 part .

[0045] The second resin composition: with reference to the first resin composition, the difference is that, based on 100 parts of polyphenylene ether, the second resin composition also includes 10 parts of phthalates (commercially purchased from Shanghai Liancheng Petrochemical Co., Ltd. ).

[0046] Prep...

Embodiment 2

[0048] The first resin composition includes: 100 parts of silica gel (commercially purchased from Dongjue Fine Chemical Co., Ltd. with the brand name of 110-2, and its molecular weight is 500,000 to 700,000); 80 parts of SiC (with a particle size of 2.5 μm); Antioxidant 1010 (commercially purchased from Shanghai Jinhai Yabao Fine Chemical Co., Ltd.) 1 part, antioxidant 1089 (commercially purchased from Nanjing Milan Chemical Co., Ltd.) 2 parts, TAF (commercially purchased from Dongguan Baosheng Plastic Chemical Co., Ltd.) 1 part 3 parts; 3 parts of titanate coupling agent (commercially purchased from Tianyang Chemical Factory, Yizheng City, Jiangsu Province, with the trade mark TM-38S); styrene-grafted maleic anhydride (commercially purchased from Shenyang Siwei Company, trade mark SWR-3F product) 5 servings.

[0049] The second resin composition: with reference to the first resin composition, the difference is that based on 100 parts of polyphenylene ether, the second resin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com