Power battery air heat management system for pure electric vehicle and operating method of system

A battery management system, a technology for pure electric vehicles, applied in electric vehicles, electric traction, electrical components, etc., can solve the problems of inability to meet the thermal management of power batteries, increase extra battery power consumption, and inability to cool batteries, etc. Low power consumption and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

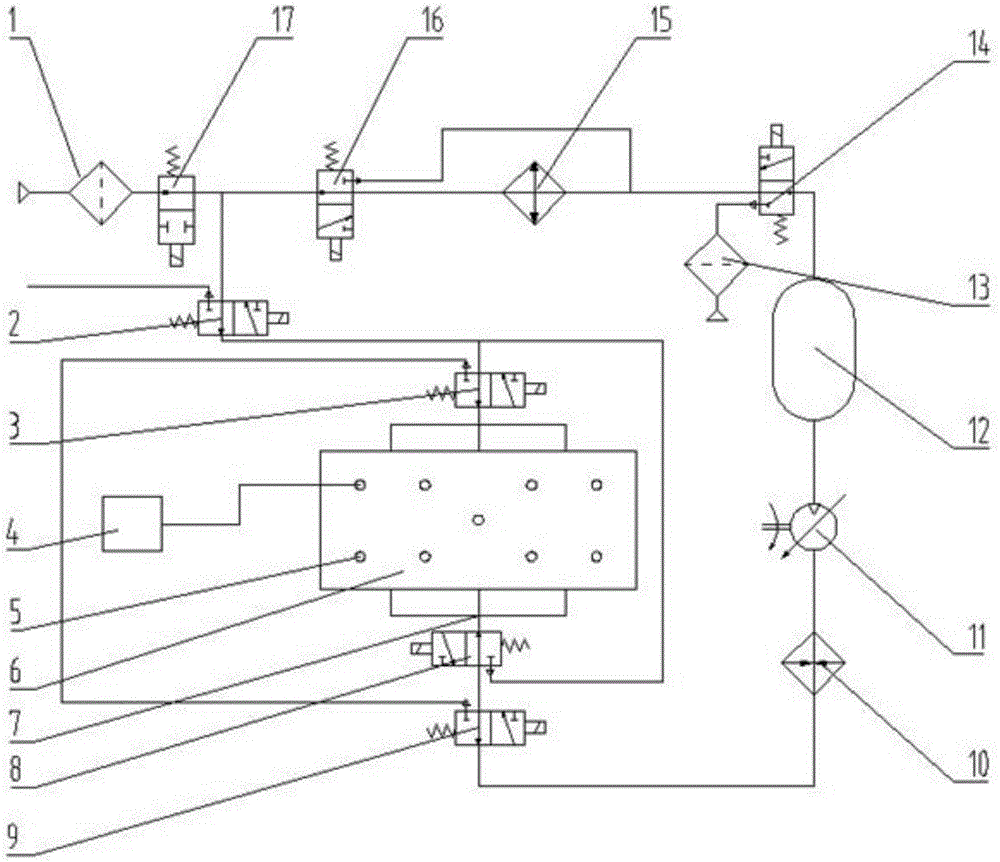

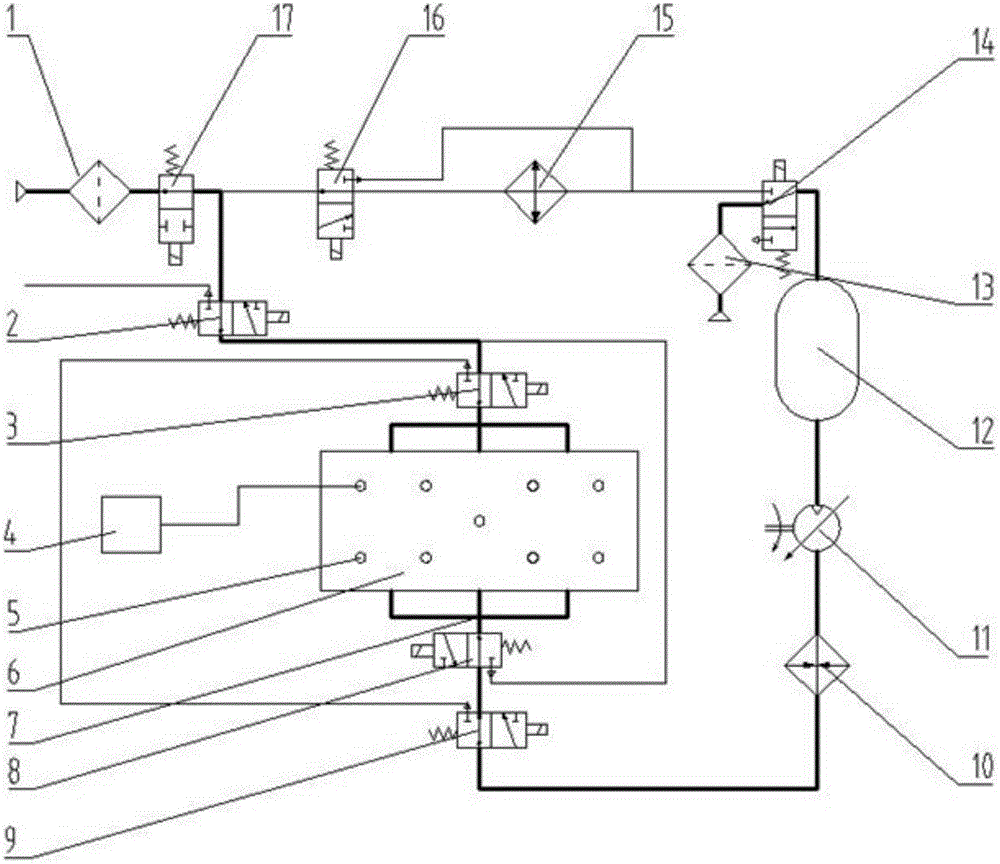

[0044] An air heat management system for a power battery of a pure electric vehicle, comprising an air distribution pipeline 7 connected to a power battery pack box 6, a temperature sensor 5 and a battery management system integrated machine 4;

[0045] One end of the air distribution pipeline 7 is sequentially connected to the heater 10, the air pump 11, the air storage tank 12, the two-position three-way electromagnetic reversing valve E14, the cooler 15, the two-position three-way electromagnetic reversing valve F16 and the two-position two-way electromagnetic reversing valve The reversing valve 17, wherein the two-position three-way electromagnetic reversing valve E14 is also connected to the two-position three-way electromagnetic reversing valve F16 through the pipeline; the other end of the air distribution pipeline 7 is connected to the two-position three-way electromagnetic reversing valve A2 and the two-position three-way electromagnetic reversing valve A2 Two-way elec...

Embodiment 2

[0053] An air heat management system for a pure electric vehicle power battery, the structure of which is as described in Example 1, the difference is that the air heat management system also includes a two-position three-way electromagnetic reversing valve B3, a two-position three-way electromagnetic reversing valve C8 and the two-position three-way electromagnetic reversing valve D9, one end of the air distribution pipeline 7 is connected to the heater 10 after connecting the two-position three-way electromagnetic reversing valve C8 and the two-position three-way electromagnetic reversing valve D9; the air distribution pipeline 7 The other end is connected to the two-position three-way electromagnetic reversing valve B3 and then connected to the two-position three-way electromagnetic reversing valve A2, and the two-position three-way electromagnetic reversing valve C7 is also connected to the two-position three-way electromagnetic reversing valve through the pipeline Valve A2...

Embodiment 3

[0056] A working method of an air heat management system for a power battery of a pure electric vehicle, using the air heat management system described in Embodiment 2, the specific working process includes the following steps,

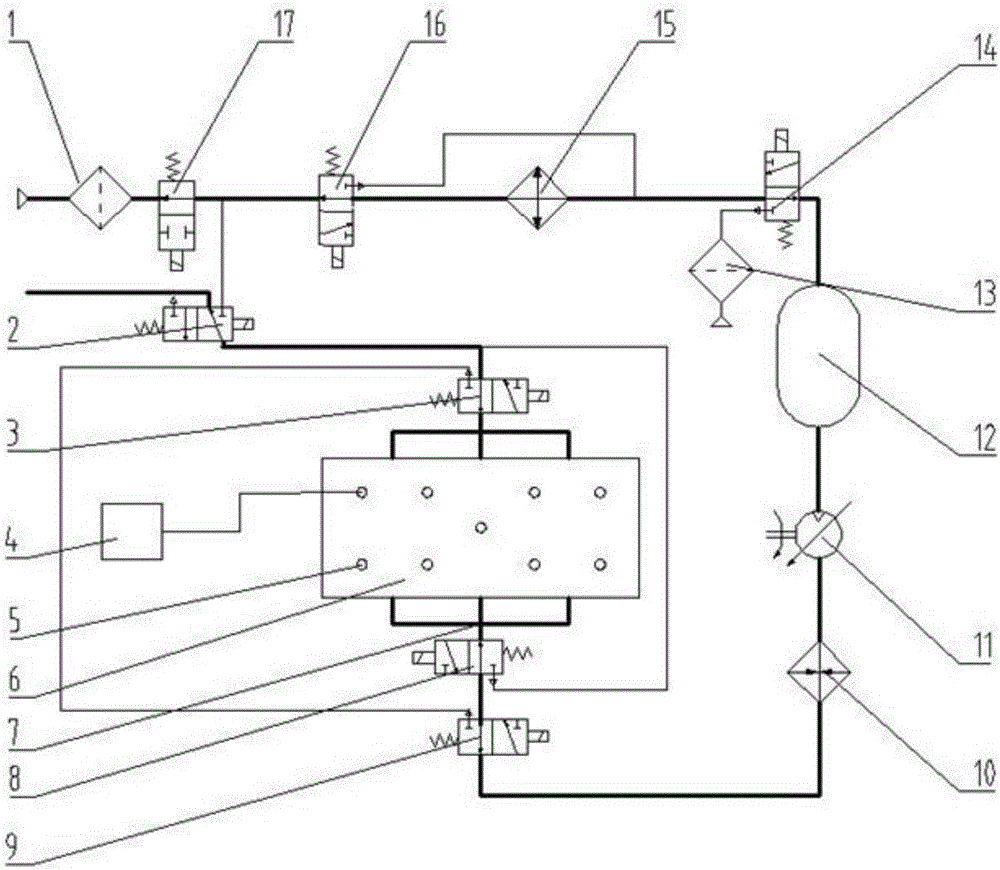

[0057] A gas storage circulation mode: (such as figure 2 shown)

[0058] When the pure electric vehicle starts to start, the all-in-one battery management system 4 starts the air storage circulation mode, at this time, the two-position three-way electromagnetic reversing valve A2 is energized, and the air pump 11 is started to perform air circulation;

[0059] In this mode, the toxic gas released by the battery in the whole system is discharged, and at the same time, it is tested whether the whole system is unobstructed, so as to prevent the system from being blocked due to long-term failure of the air filter element or internal structural failure, and to ensure that there is enough air in the air storage tank. Air, ready for internal circulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com