Permanent magnet synchronous motor torque control method

A permanent magnet synchronous motor and torque control technology, which is applied in the field of electric power transmission, can solve the problems of the difficulty of real-time parameters of the motor and the difficulty of high-precision control of torque, etc., so as to improve the current utilization rate, reduce the workload, The effect of ensuring torque control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

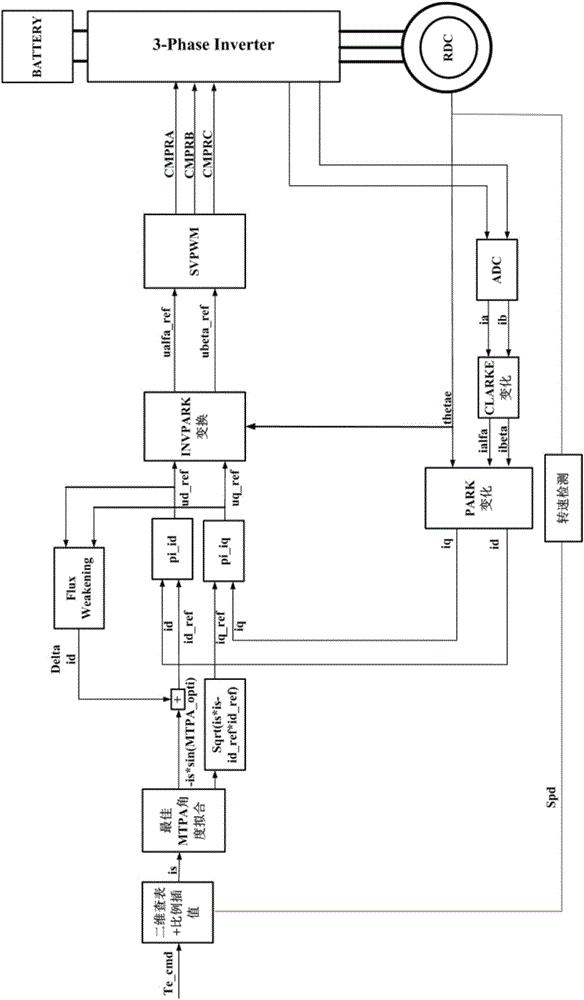

[0047] In a feasible implementation manner, the permanent magnet synchronous motor torque control method includes the following steps:

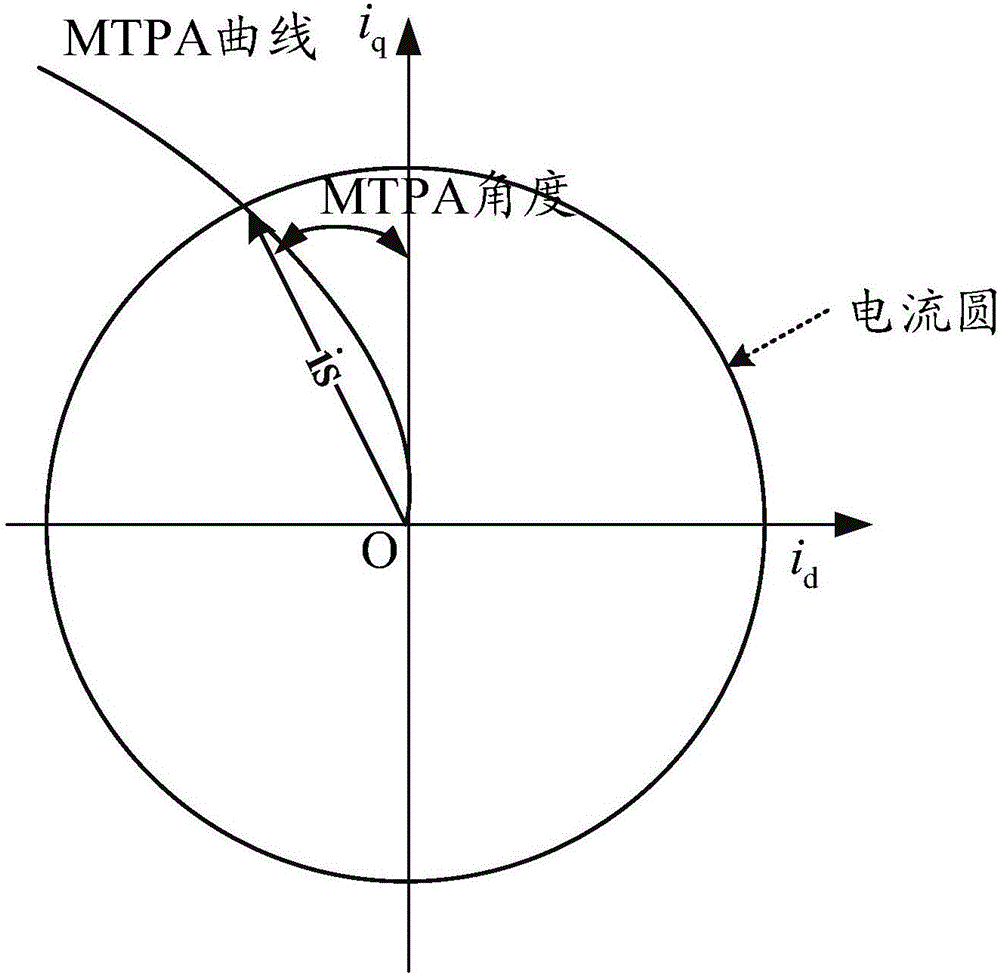

[0048] (1) Carry out MTPA angle experiment, draw the two-dimensional form of torque about MTPA angle and target current;

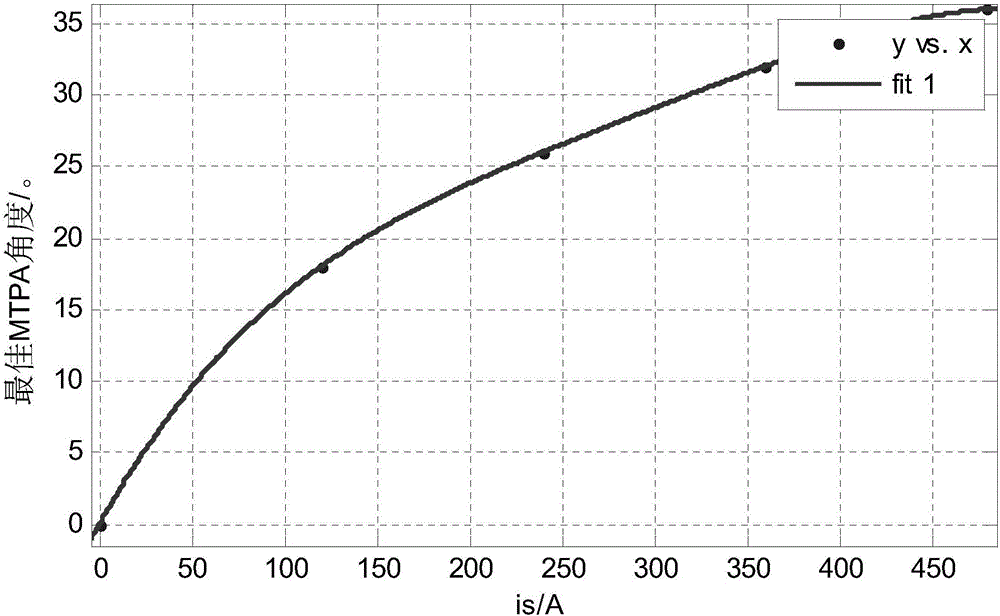

[0049] (2) Fitting the optimal MTPA angle into a line about the target current i s The quartic curve of , and get the quartic polynomial of the curve;

[0050] (3) Carry out a bench experiment, and draw a two-dimensional table of the target current with respect to the current rotational speed and the target torque;

[0051] (4) According to the two-dimensional table of the target current about the current speed and the target torque, the actual required target current is obtained through a proportional interpolation algorithm;

[0052] (5) Calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com