A deep-sea shellfish harvesting system and its harvesting method for continuous operation by two ships

A shellfish harvesting technology, which is applied to fishing boats, fish farming, animal husbandry, etc., can solve the problems that the position of lifting and releasing nets cannot be guaranteed at the same place, high labor costs, and reduced operating efficiency, so as to save operating time and labor costs, improved operating efficiency, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

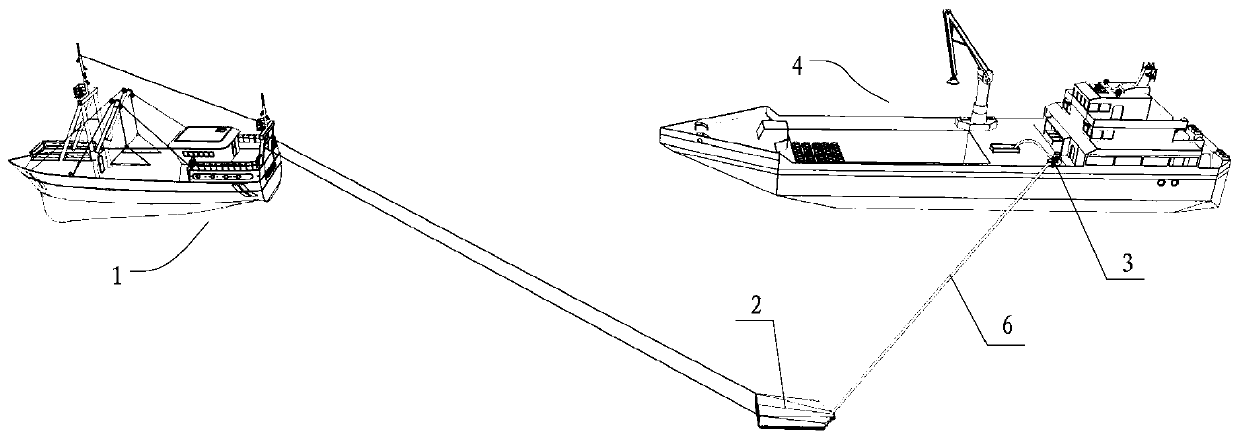

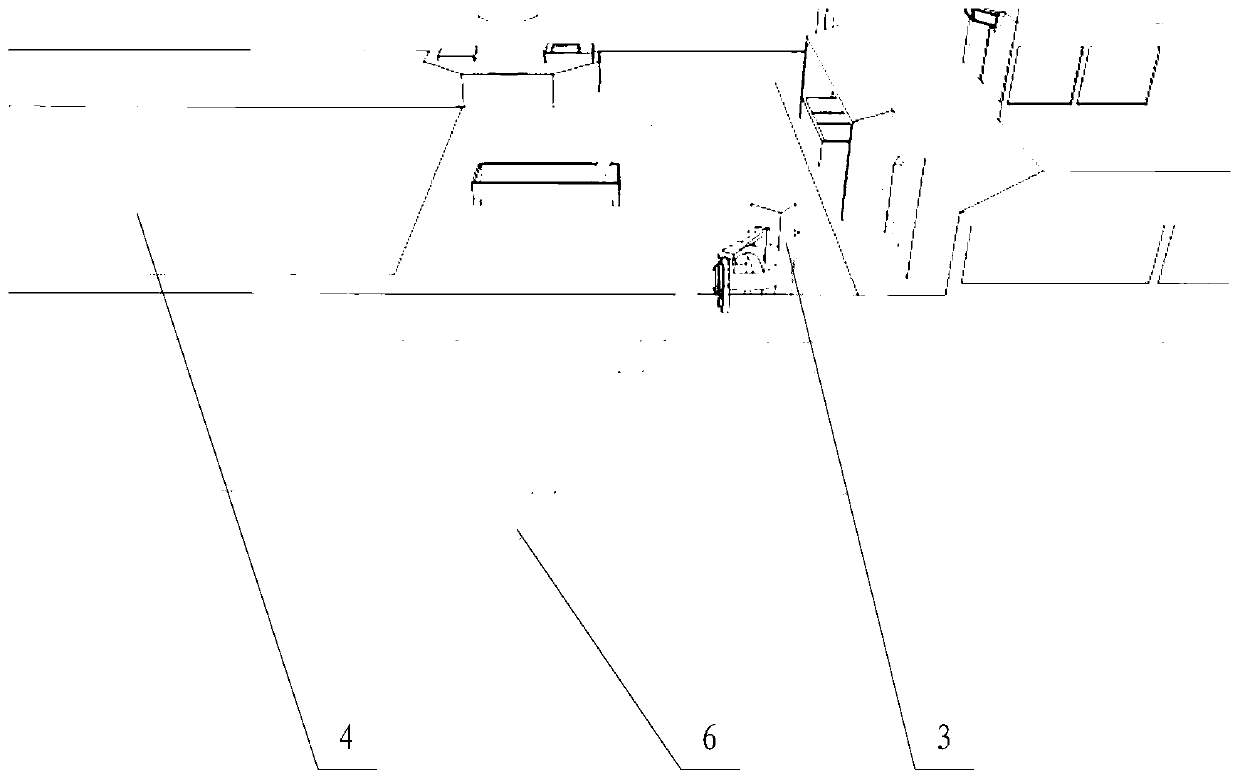

[0031] The configuration of the complete set of equipment for the double-vessel continuous operation deep-sea shellfish harvesting system is as follows:

[0032] The tugboat has 1,300 horsepower and a displacement of 200 tons. It is equipped with automatic net lifting and net releasing equipment. It has precise positioning and navigation functions, and can accurately navigate according to the set track.

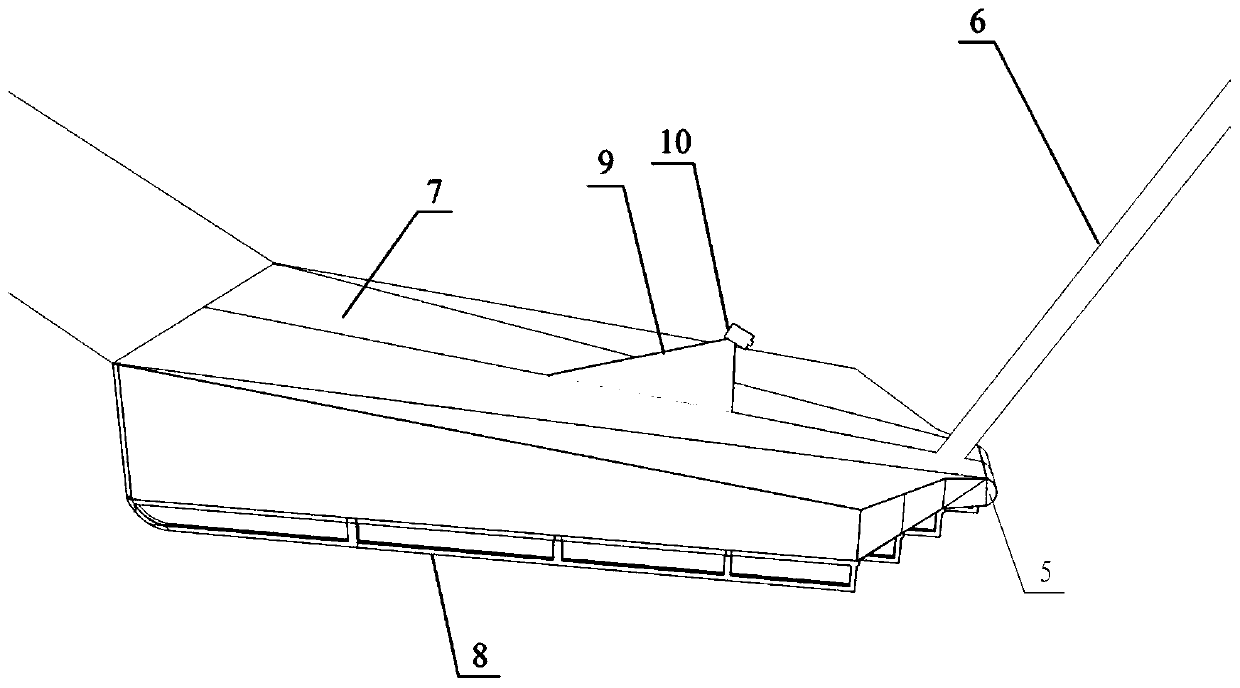

[0033] Ecological bottom trawl 2, with a net mouth width of 5 meters and a net mouth height of 1.0 meters, the main body of the net 7 is 20 cm above the ground, the bag net 5 is fully loaded with fish catches of 1.5 to 2 tons, and the bag net 5 is equipped with video monitors for Check the catch in the bag net 5 in real time on the harvesting ship 4;

[0034] Self-priming pump 3 rated flow 592m 3 / h, the pipe diameter is 250mm, the head is 35.5 meters, and the output power of the diesel engine is 110kw;

[0035] The harvesting ship has 4,800 horsepower, a dead weight of 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com