Garlic cleaving device

A technology for splitting garlic, which is applied in the field of garlic splitting devices, can solve problems such as unfavorable follow-up production, crushing, and increased processing costs, and achieve the effects of simple structure, uniform splitting, and improved integrity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

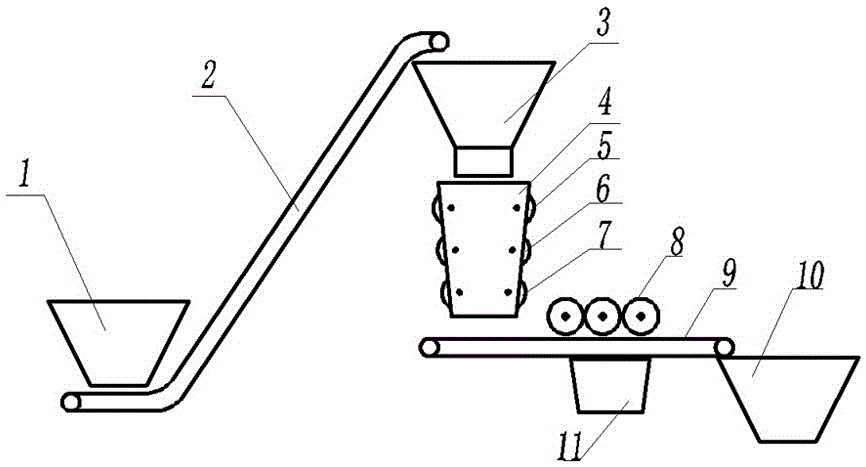

[0014] A garlic splitting device includes a feeding mechanism, a splitting mechanism and a skin pressing mechanism. The feeding mechanism includes an upper material bin 1 and a baffle conveyor belt 2, and the splitting mechanism includes a lower bin 3 and a splitter 4, and the splitter 4 is located at the vertical lower part of the lower bin 3, and the splitter 4 is provided with two A group of buffer rollers, each group of buffer rollers includes an upper buffer roller 5, a middle buffer roller 6 and a lower buffer roller 7, the gap between the two groups of buffer rollers decreases from top to bottom, the gap between the upper buffer rollers is 12-14cm, and the middle buffer roller The roller gap is 6-7cm, and the gap between the lower buffer rollers is 3-3.5cm. The upper buffer roller 5 is provided with two helical raised ribs, and the middle buffer roller 6 is provided with four helical raised ribs; The leather mechanism is located at the lower part of the split mechanism,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com