Incense thread applicator for filter sticks

A technology of applying device and fragrance thread, which is applied in the fields of e-liquid filter, application, food science, etc., can solve problems such as failure to automatically detect disconnection, inaccurate control of the amount of fragrance added, and inability to adjust the tension of cotton thread, etc. It is not easy to achieve. The effect of disconnection, proper tension and automatic tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

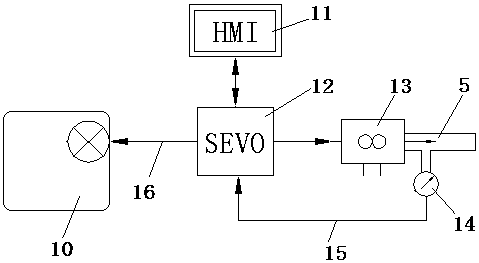

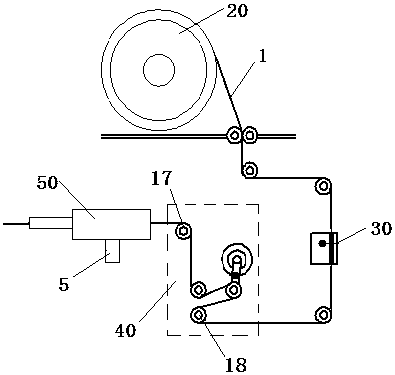

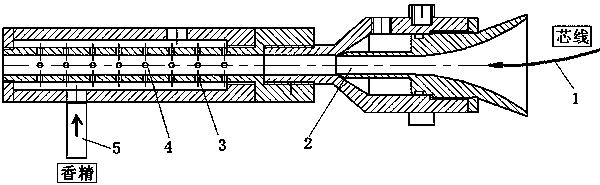

[0021] The incense thread application device structure, parts and control system of the filter stick of the present invention are such as figure 1 , 2 As shown in , 3, it has a servo controller, and it also has a core wire extraction module, a tension adjustment module, a mixing module, and a fragrant thread application module connected in sequence according to the walking path of the core wire; the mixing module is also connected to the essence flow control module; the servo The controller is respectively connected with the forming host, the core wire extracting module and the incense string applying module through the control circuit and controls their start and stop.

[0022] The essence is output to the mixing device through the essence flow control module, and the core wire enters the mixing module after passing through the extraction device, the broken wire detection module and the tension adjustment module, and the essence infiltrates the core wire or absorbs the essenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com