A method for improving the quality and mechanical properties of 7xxx aluminum alloy friction stir welded joints

A friction stir and aluminum alloy technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems that the cooling rate is difficult to reach the critical cooling rate of the alloy, the quality of the welding joint is difficult to control, and the efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

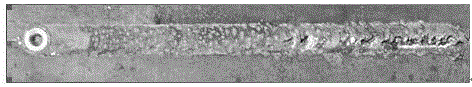

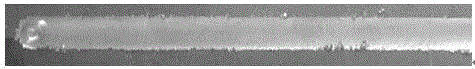

[0022] In this example, friction stir welding is carried out on 7XXX aluminum alloy plates in T6 state after 1.8 mm. After welding, they are cooled with room temperature water and 10% PAG solution respectively. The rate was 1 °C / min. Such as figure 1 As shown, the welded joint cooled by water at room temperature is prone to defects and has poor appearance quality, while the welded joint cooled by 10% PAG solution has no defects and beautiful appearance quality, as figure 2 .

Embodiment 2

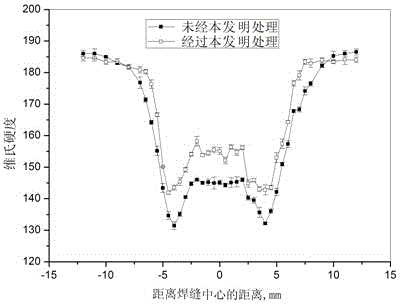

[0024] In this embodiment, friction stir welding is performed on a 1.8 mm thick T7-state 7XXX aluminum alloy plate (chemical composition is listed in Table 1). After welding, one plate is air-cooled and then subjected to natural aging treatment; the other plate is processed by the method of the present invention, that is, after welding, it is cooled with a 10% PAG solution, placed in a 45°C environment for 240h, and then heated to 0.25°C / min. 110°C, keep warm for 4h, then take it out and cool it naturally in still air. Test and compare the Vickers hardness of the weld zone, such as image 3 It is shown that the method of the present invention can increase the hardness of the weld zone, especially in the nugget zone and the thermal-mechanical-affected zone, thereby improving the mechanical properties of the welded joint.

[0025] Table 1 Chemical composition of 7XXX series aluminum alloy sheets in T7 state (wt%)

[0026] element Zn Mg Cu Zr mn Fe Si T...

Embodiment 3

[0028] In this example, the 2.5 mm thick T4 state 7XXX aluminum alloy plate is subjected to friction stir welding. After welding, the PAG solution with a concentration of 5% and air cooling are used respectively, and then the natural aging time is different or the temperature is slowly raised after being placed in a 60°C environment for different times. To 121°C, the heating rate is 0.4°C / min, and finally test the tensile properties of the welded joint at room temperature. Table 2 shows the chemical composition of the alloys. Table 3 shows the room temperature tensile properties of the welded joints after different treatments.

[0029] The method of the invention can not only significantly improve the strength of the welded joint and ensure higher elongation, but also greatly shorten the follow-up processing time and improve production efficiency.

[0030] Table 2 Chemical composition of 7XXX series aluminum alloy sheets in T4 state (wt%)

[0031] element Zn Mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com