Preparation method and preparation device of high-efficiency anti-pollution reverse osmosis membrane

A reverse osmosis membrane, anti-pollution technology, used in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problems of short service life, no antibacterial and bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

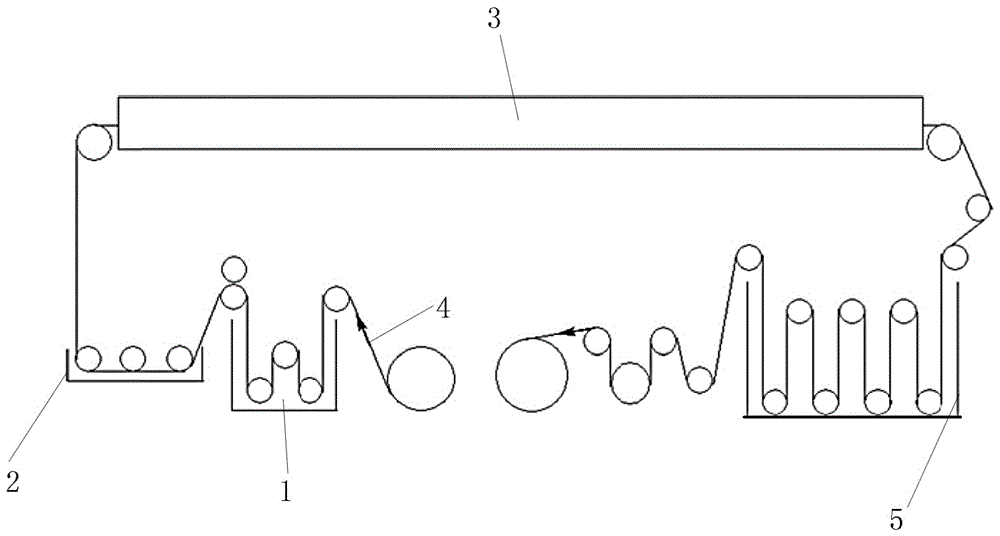

[0028] A method for preparing an efficient anti-pollution reverse osmosis membrane, comprising the following steps:

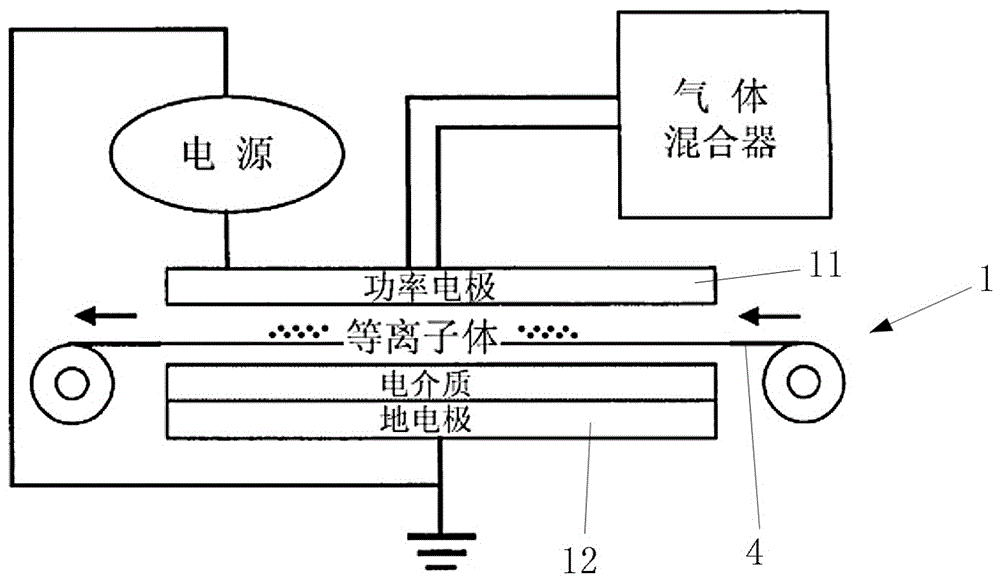

[0029] Plasma modification treatment

[0030] Pass the reverse osmosis membrane substrate at a speed of 0.5m / min through a plasma device with a plate spacing of 2mm, and introduce carbon dioxide gas with an atmosphere of 40 sccm, and the frequency of the radio frequency power used by the plasma device is 8KHz.

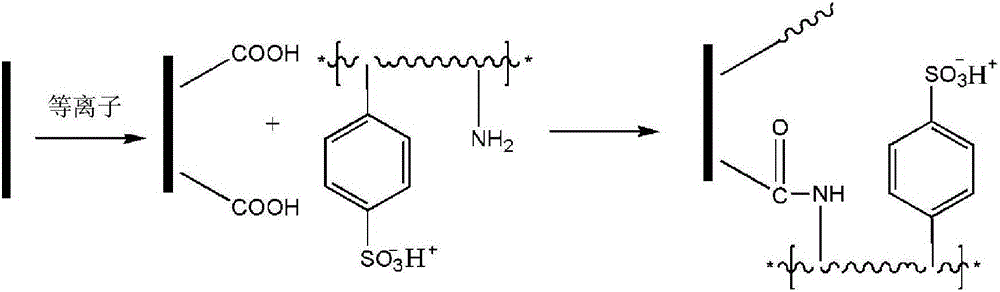

[0031] Membrane Surface Graft Modification

[0032] Pass the plasma-treated reverse osmosis substrate through a solution containing 20% polystyrene sulfamic acid at a speed of 0.5 m / min, and the solvent used is polyvinylpyrrolidone and dimethyl Formamide mixed solution.

[0033] drying treatment

[0034] The reverse osmosis modified by surface grafting is processed at a speed of 0.5 m / min through an oven section with a temperature of 60°C.

[0035] wind up

[0036] Pass the dried reverse osmosis membrane through the air-cooling system and then wi...

Embodiment 2

[0038] A method for preparing an efficient anti-pollution reverse osmosis membrane, comprising the following steps:

[0039] Plasma modification treatment

[0040] Pass the reverse osmosis membrane substrate at a speed of 0.6m / min through a plasma device with a plate spacing of 2mm, and introduce carbon dioxide gas with an atmosphere of 40 sccm, and the frequency of the radio frequency power used by the plasma device is 8KHz.

[0041] Membrane Surface Graft Modification

[0042] Pass the plasma-treated reverse osmosis substrate through a solution containing 20% polystyrene sulfamic acid at a speed of 0.6 m / min, and the solvent used is polyvinylpyrrolidone and dimethyl Formamide mixed solution.

[0043] drying treatment

[0044] The reverse osmosis modified by surface grafting is processed at a speed of 0.6m / min through an oven section with a temperature of 60°C.

[0045] wind up

[0046] Pass the dried reverse osmosis membrane through the air-cooling system and then win...

Embodiment 3

[0048] A method for preparing an efficient anti-pollution reverse osmosis membrane, comprising the following steps:

[0049] Plasma modification treatment

[0050] Pass the reverse osmosis membrane substrate at a speed of 0.8m / min through a plasma device with a plate spacing of 2mm, and introduce carbon dioxide gas with an atmosphere of 50 sccm, and the frequency of the radio frequency power used by the plasma device is 10KHz.

[0051] Membrane Surface Graft Modification

[0052] Pass the plasma-treated reverse osmosis substrate through a solution containing 20% polystyrene sulfamic acid at a speed of 0.8 m / min, and the solvent used is polyvinylpyrrolidone and dimethyl mixed solution of methyl formamide.

[0053] drying treatment

[0054] The reverse osmosis modified by surface grafting is processed at a speed of 0.8m / min through an oven section with a temperature of 50°C.

[0055] wind up

[0056] Pass the dried reverse osmosis membrane through the air-cooling system a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com