Size mixing method for malt syrup preparation based on linked control of rotation speed and temperature

A technology of linkage control and maltose syrup is applied in the direction of maltose production, chemical instruments and methods, mixers with rotating stirring devices, etc. It can solve problems such as insufficient slurry mixing, inability to meet production needs, and insufficient heat exchange, etc., to achieve The effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

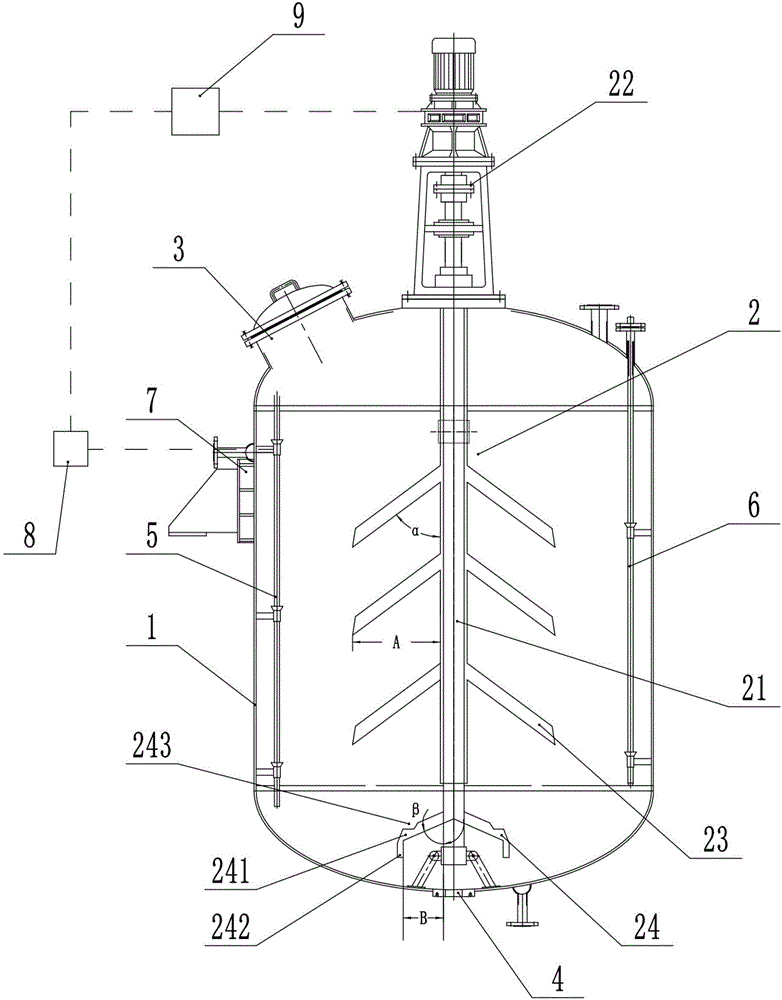

[0021] Embodiment 1: as figure 1 As shown, the mixing tank for maltose syrup preparation in this embodiment includes a tank body 1 and a stirring assembly 2 installed in the tank body 1. The tank body 1 is provided with an upper inlet 3 and a bottom outlet 4, and the stirring assembly 2 includes a rotating The stirring shaft 21 installed in the center of the tank body 1 and coincident with the central axis of the tank body 1, the deceleration motor 22 that drives the stirring shaft 21 and is placed outside the top of the tank body 1, the stirring shaft 21 is provided with a The middle stirring blade 23 in the middle of the inner cavity and the bottom stirring blade 24 positioned at the bottom of the inner cavity of the tank body 1, the middle stirring blade 23 includes multiple layers spaced up and down, and is located symmetrically on both radial sides of the stirring shaft 21; the bottom stirring blade 24 is a single-layer structure, symmetrically arranged on both radial sid...

Embodiment 2

[0023] Embodiment 2: As a further improvement of the above embodiment 1, such as figure 1 As shown, in the present invention, the inner cavity of the tank body 1 is equipped with a temperature detection rod 5 and a height detection rod 6 arranged near its inner wall, and the outer side of the tank body 1 is provided with a visible window for observing the temperature detection rod 5 and the height detection rod 6 7. The stirring temperature and the height of the slurry in the tank body 1 can be directly observed from the viewing window 7 .

Embodiment 3

[0024] Embodiment 3: As a further improvement of the above embodiment 1, such as figure 1 As shown, the radial span A of the middle stirring blade 23 in the tank body 1 is greater than the radial span B of the bottom stirring blade 24 in the tank body 1 . The span of the bottom stirring blade 24 should not be too large, so as to avoid its deformation under the large slurry stirring resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com