Machining platform for SMT laser template spraying device

A technology of spraying equipment and processing platform, applied in the direction of spraying device, etc., can solve the problems of nano-solution entering and adsorption device failure, etc., and achieve the effect of avoiding failure, convenient operation and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

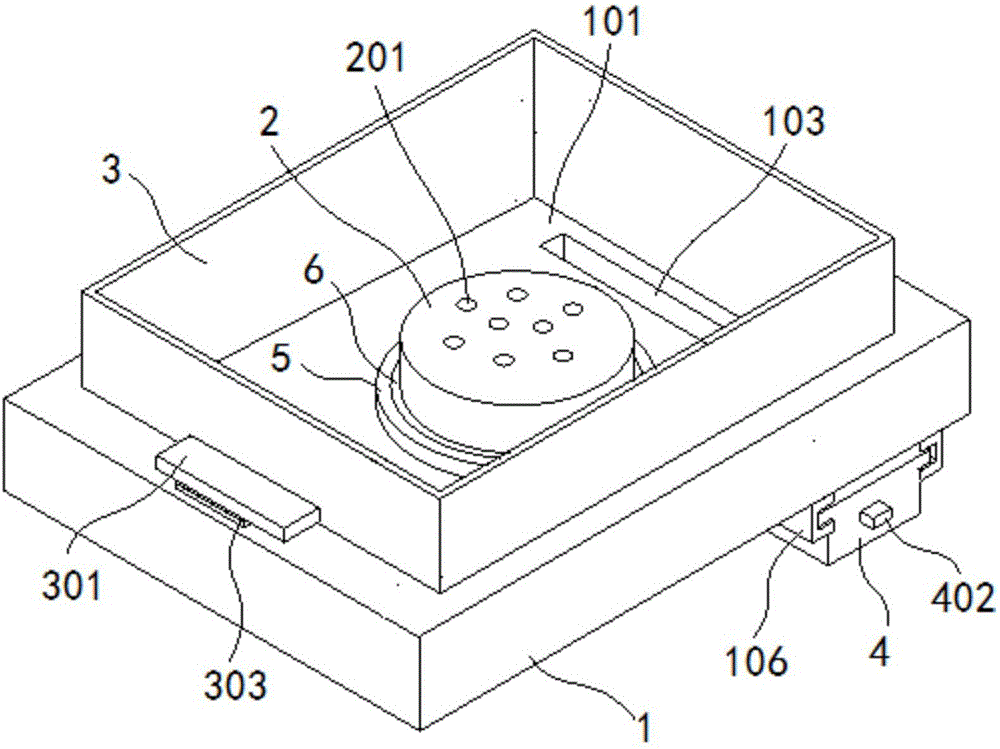

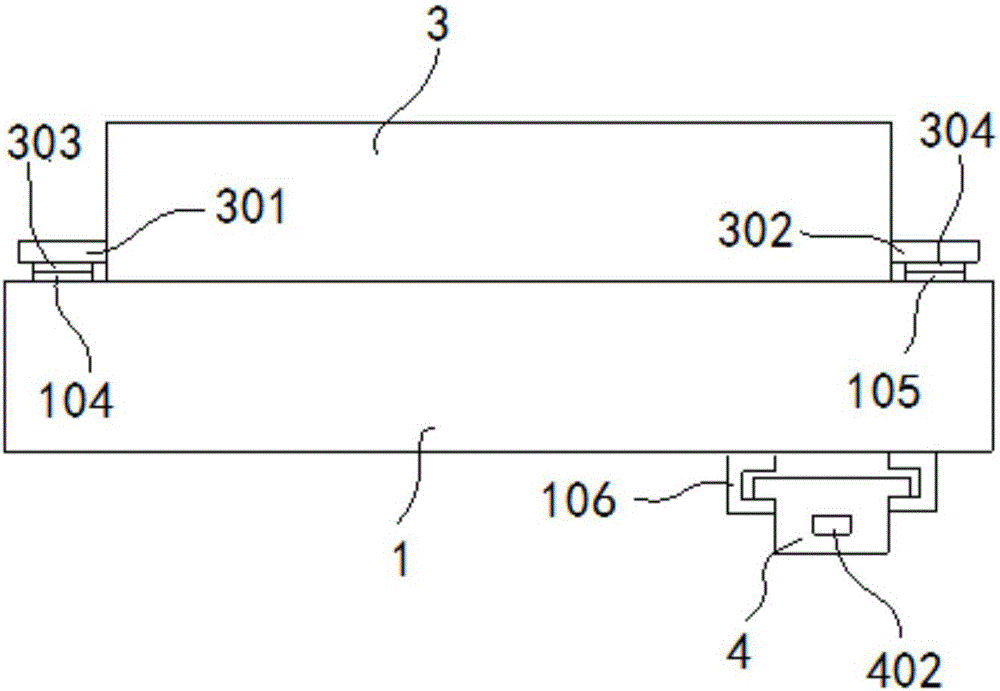

[0029] Such as figure 1 , figure 2 As shown, the processing platform for SMT laser template spraying equipment of the present invention includes:

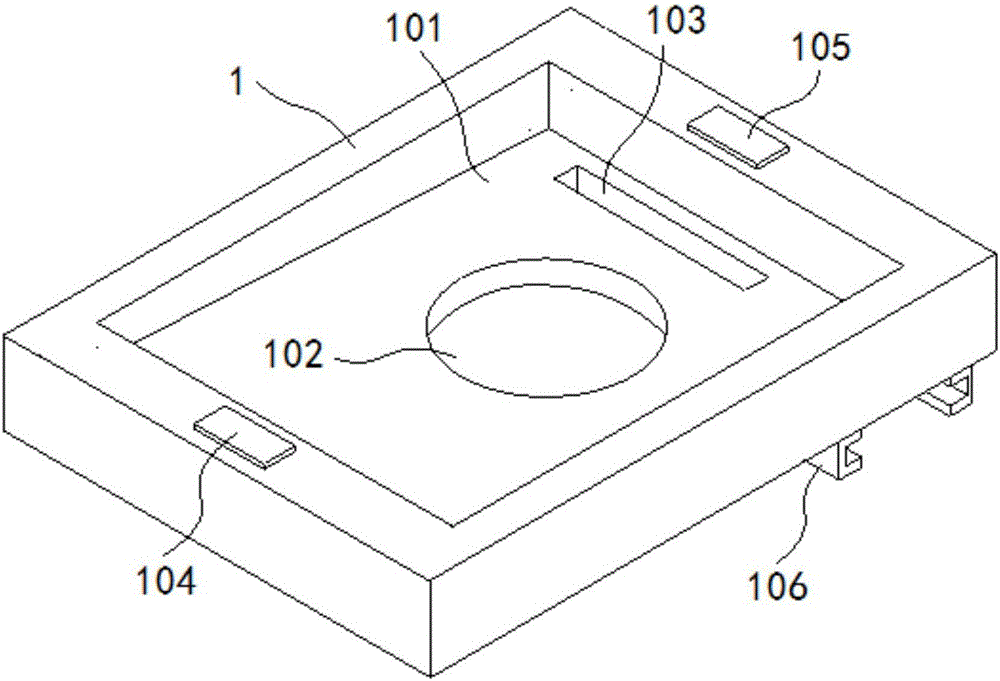

[0030] Backplane 1, such as image 3 As shown, a rectangular concave platform 101 is formed on the base plate 1, the upper surface of the concave platform 101 is inclined from left to right, and a through hole 102 is formed at the center of the concave platform 101. The concave platform 101 The right side of the base plate 1 is formed with a drain tank 103, and the upper surface of the bottom plate 1 is fixedly connected with a first magnet chuck 104 and a second magnet chuck 105 which are oppositely arranged. A slot 106 is formed under the bottom plate 1, and the insert The groove 106 is arranged directly below the drain groove 103 .

[0031] The vacuum suction plate 2 is fixed on the concave platform 101 after passing through the through hole 102 , and the upper end of the vacuum suction plate 2 exposes the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com