Single excitation longitudinal bending composite vibration ultrasonic transducer

An ultrasonic transducer and compound vibration technology, which is applied in the direction of the fluid using vibration, can solve the problems of tool wear, workpiece edge collapse, large cutting force, etc., and achieves the effect of simple structure, reasonable design, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

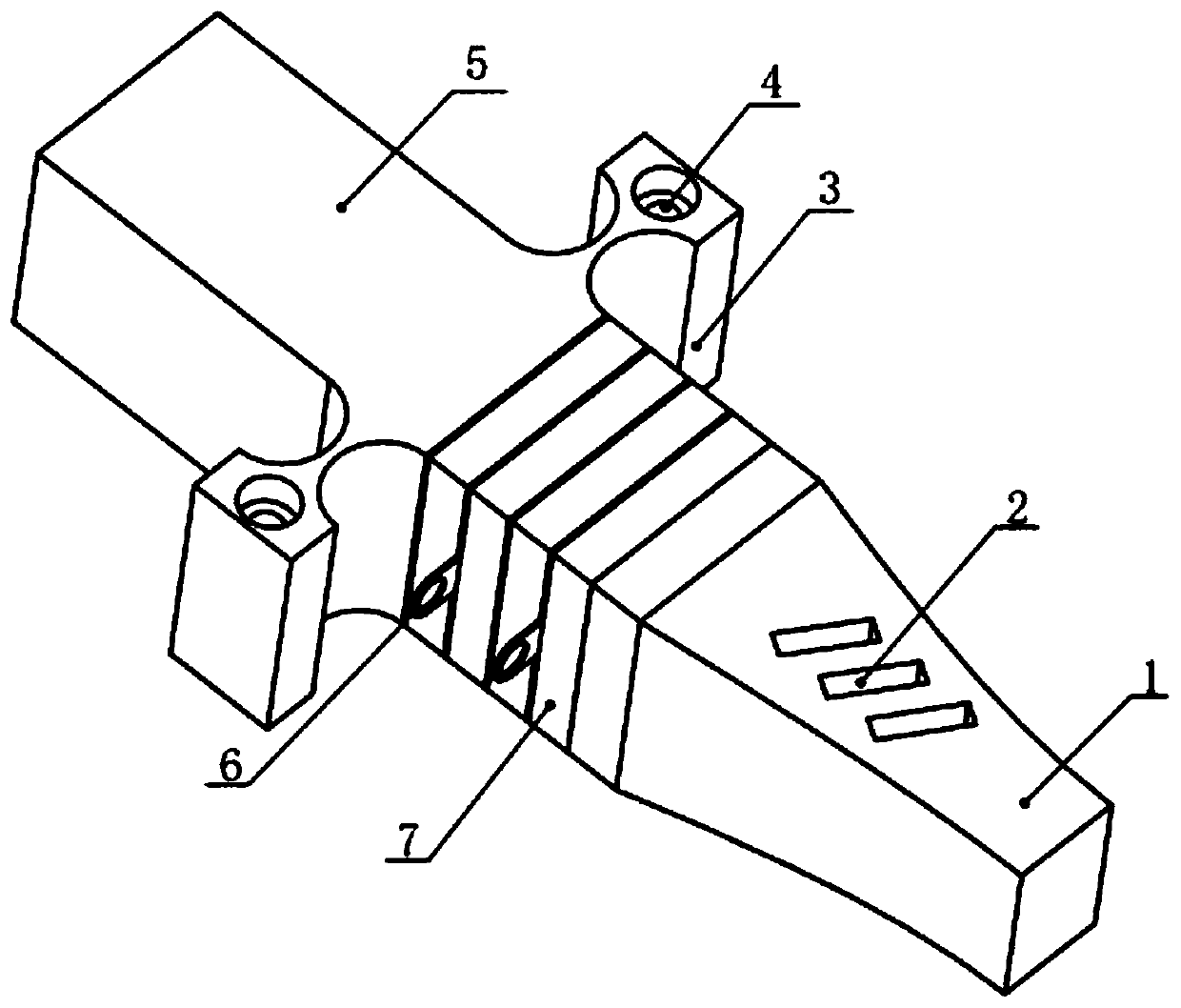

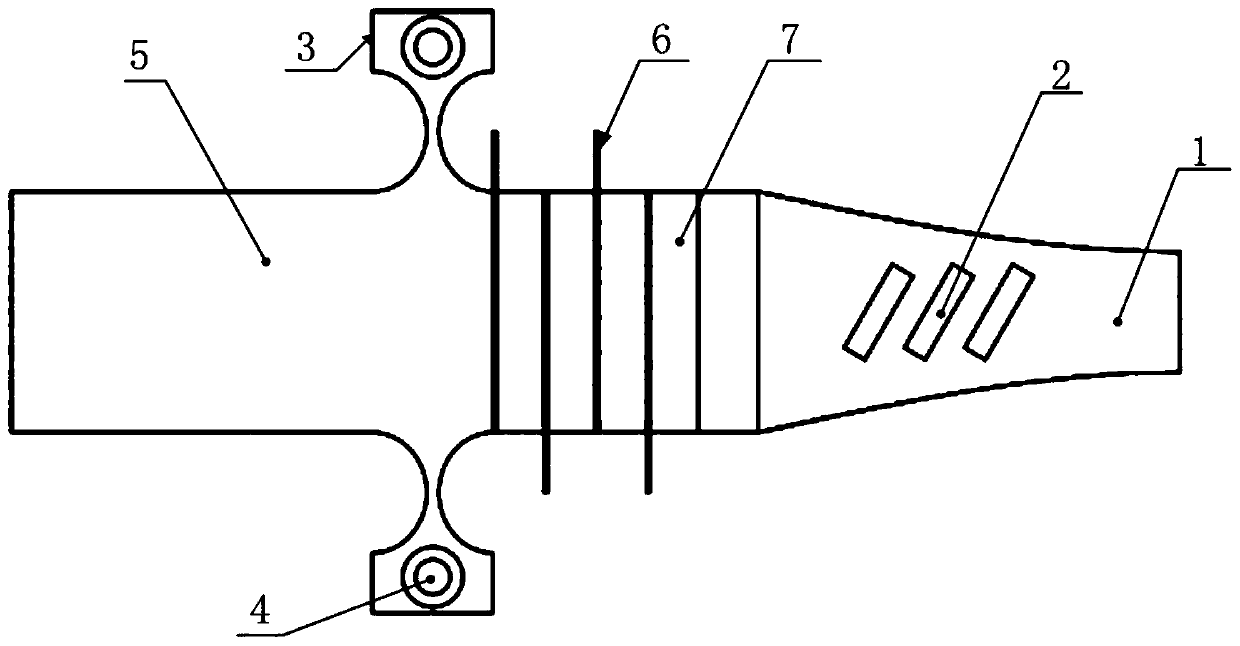

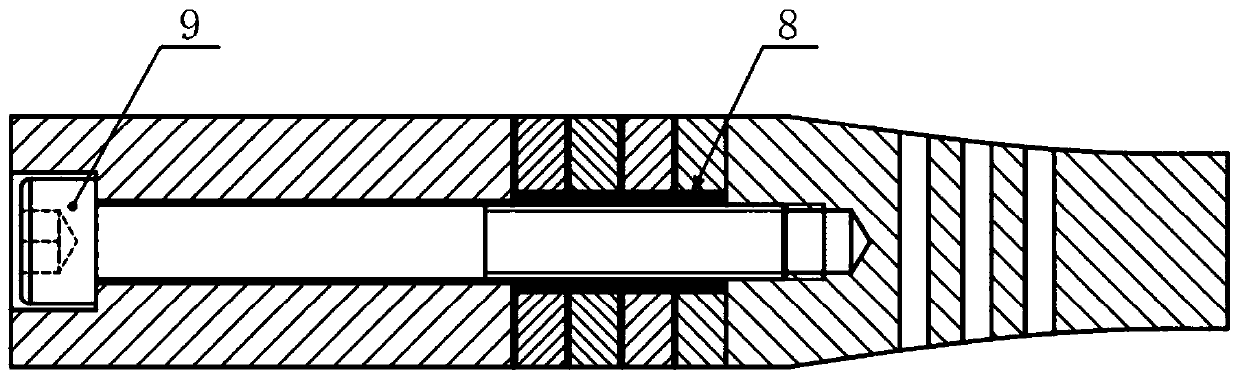

[0016] see Figure 1 ~ Figure 3 , a single-excitation longitudinal-bending composite vibration ultrasonic transducer, comprising a front cover 1 and a rear end cover 5, between which are interposed copper electrodes arranged at intervals 6 and the piezoelectric ceramic wafer 7 constitute a sandwich structure, the front cover 1, the rear end cover 5, the copper electrode 6 and the piezoelectric ceramic wafer 7 are assembled together by pre-tightening screws 9 .

[0017] An insulating sleeve 8 is provided at the position where the copper sheet electrode 6 and the piezoelectric ceramic wafer 7 are arranged on the pre-tightening screw 9, and the copper sheet electrode 6 and the piezoelectric ceramic wafer 7 are sleeved on the On the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com