Steel plate automatic drilling robot

A robot and automatic technology, applied in the field of robots, can solve the problems of increasing labor costs and low punching efficiency, and achieve the effect of high machine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example

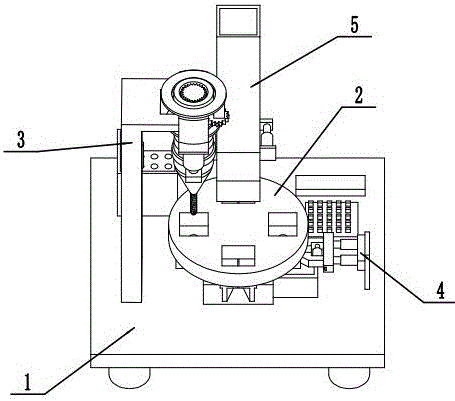

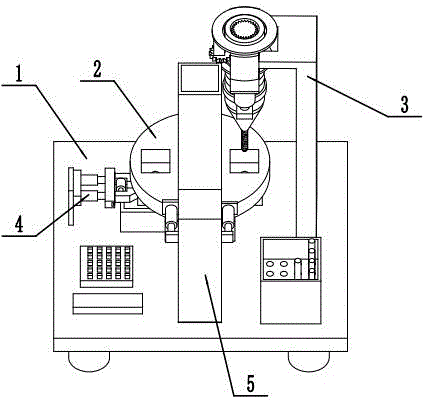

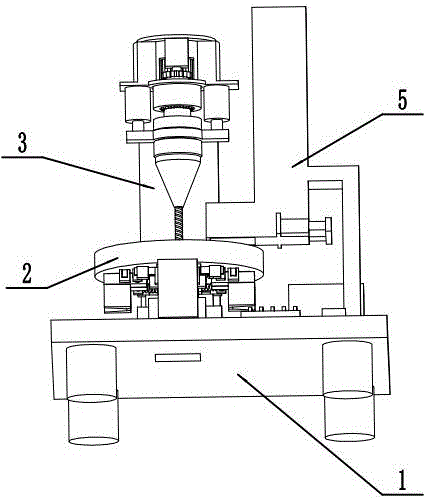

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 As shown, a steel plate automatic drilling robot includes a base 1, a circular turntable 2, a punching mechanical arm 3, an iron sheet falling part 4, and an iron sheet storage part 5, characterized in that: the circular turntable 2 The bottom surface of the stepping motor 206 is installed in the stepping motor fixing seat 104 of the base 1, and the bottom end of the punching manipulator support frame 301 of the punching manipulator 3 is installed on the punching manipulator fixing seat 102 of the base 1. The iron piece falling portion fixing frame 401 of the iron piece falling portion 4 is laterally mounted on the iron piece falling portion fixing seat 106 of the base 1, and the iron piece storage portion supporting frame of the iron piece storing portion 5 The lower part of 501 is installed on the fixi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap