Portable flame cutting machine for cutting oval shape and application method thereof

A flame cutting machine and portable technology, which is applied to gas flame welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of manual cutting quality not meeting the requirements and occupying a lot of labor, so as to achieve convenient portability, improve Product quality, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

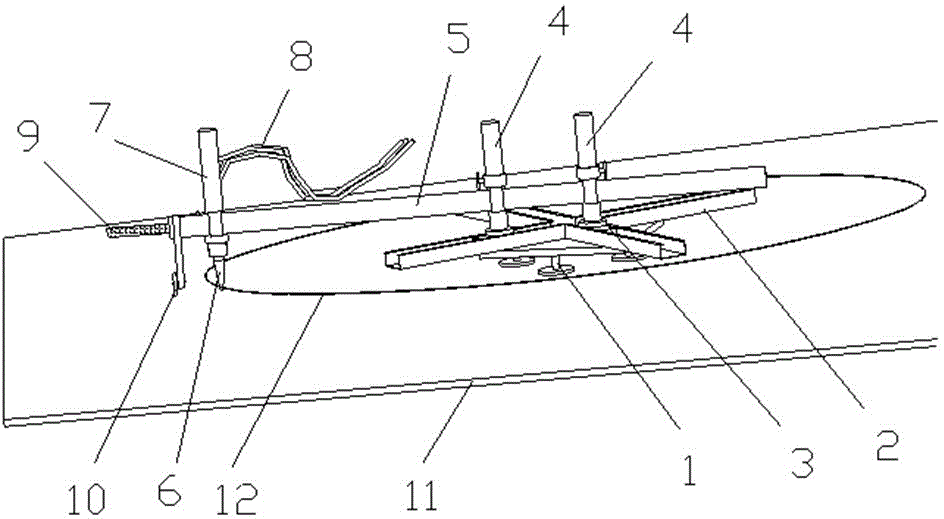

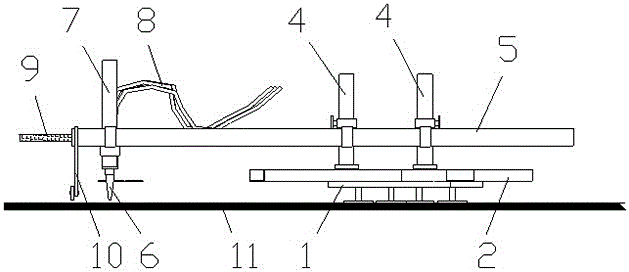

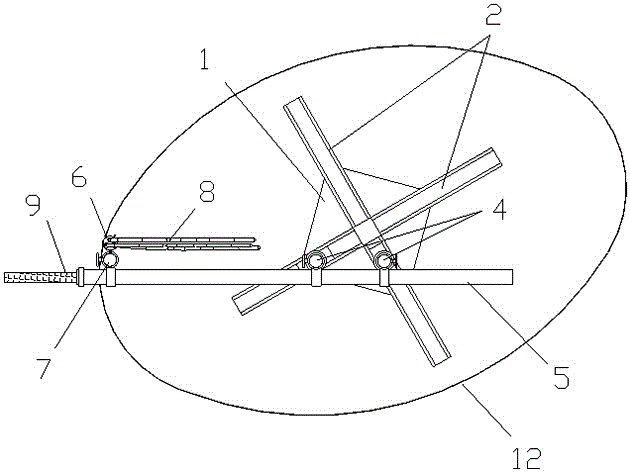

[0024] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-4 shown).

[0025] A portable flame cutting machine for cutting an ellipse, characterized in that it is mainly composed of a flame cutting machine and an ellipse control mechanism; the ellipse control mechanism includes a magnetic base 1, a cross-shaped chute 2, and a radius adjustment bar 5 and cutting nozzle height adjustment rod 7, the cross-shaped chute 2 is fixedly installed on the magnetic base 1; the vertical and horizontal two chutes of the cross-shaped chute 2 are all provided with slide blocks 3 (3 slide blocks for each can slide in the corresponding vertical or horizontal chute on the cross-shaped chute 2), and each slider 3 is connected with a (vertically arranged) radius difference adjustment rod 4 through a bearing (the radius difference adjustment rod 4 can free ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com