Carbon dioxide gas shielded welding method for austenitic stainless steel pressure vessel

A technology of austenitic stainless steel and carbon dioxide, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unreliable welding quality, low welding efficiency, high welding efficiency, etc., and achieve high production efficiency and fast deposition speed , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means realized by the present invention, the creation features, the achievement of the purpose and the effect clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

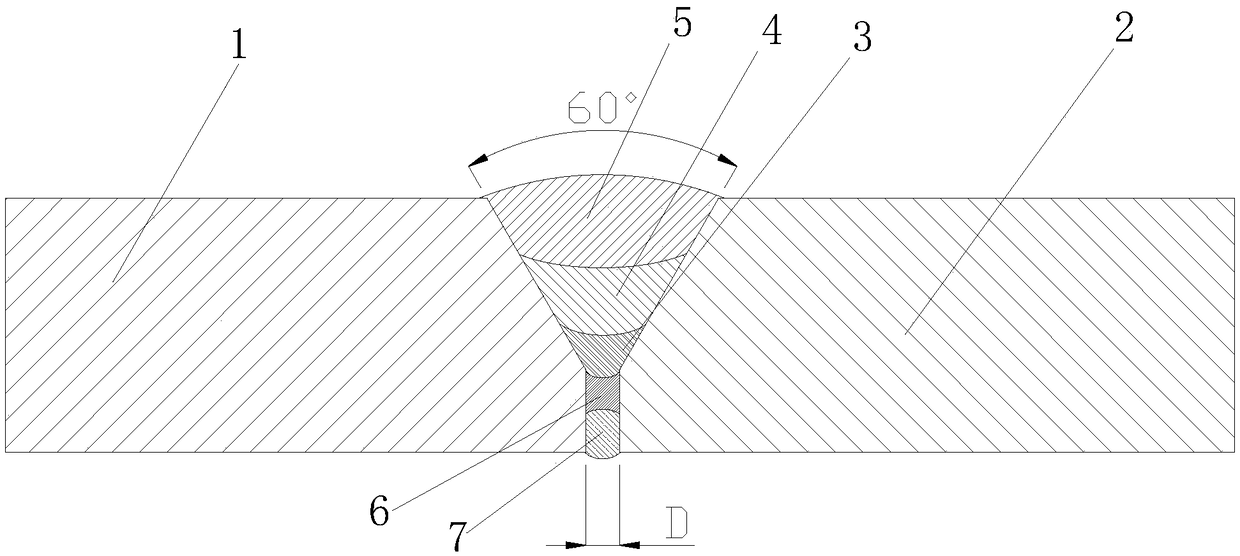

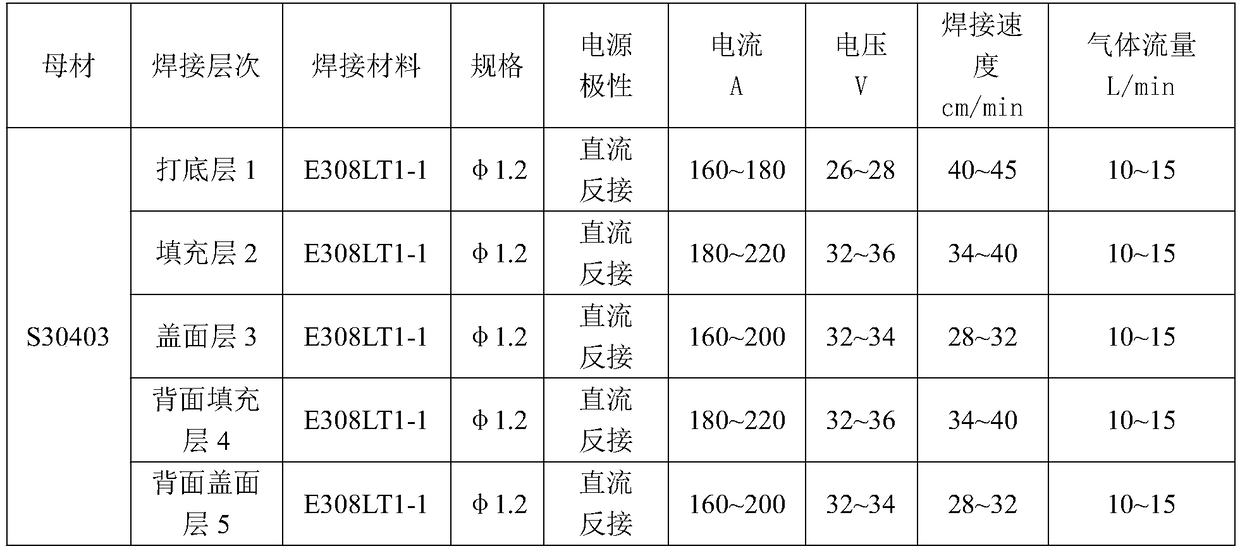

[0020] As a preferred embodiment of the present invention, please refer to the appendix figure 1 and figure 2 :

[0021] A carbon dioxide gas shielded welding method for an austenitic stainless steel pressure vessel, comprising the following steps in sequence:

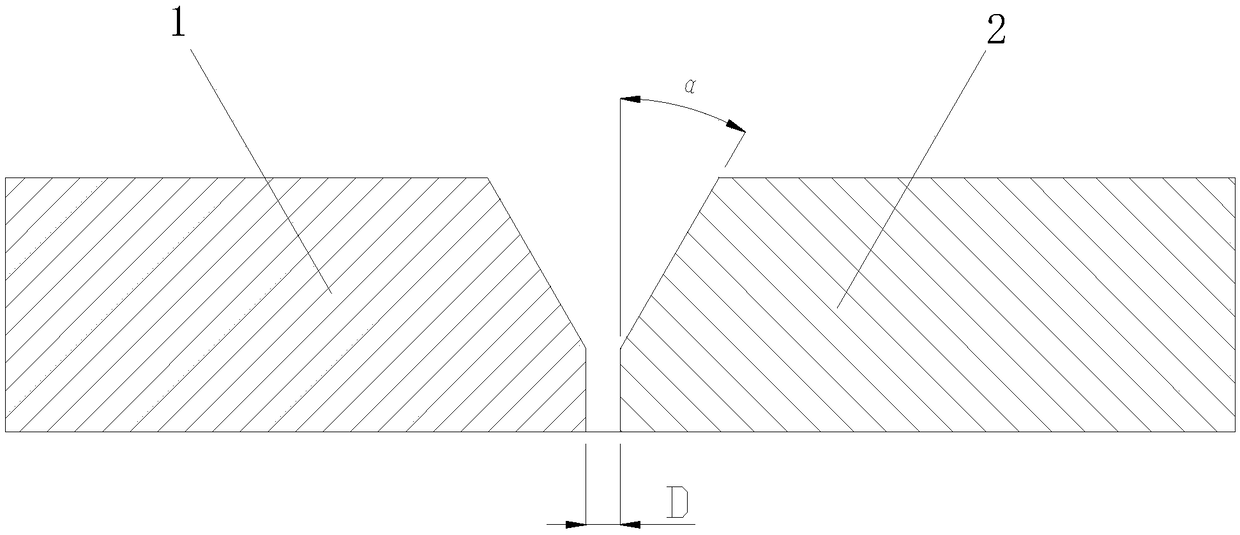

[0022] Step 1: The butt area of the tube sections 1 and 2 of the austenitic stainless steel pressure vessel to be welded is processed to form a V-shaped groove, the groove angle is 30° on one side, and the depth of the groove is 2 / 2 of the thickness of the base metal. 3, blunt edge 1 ~ 2mm;

[0023] Step 2: Assemble the barrel sections so that the assembly gap is 1-2mm, and grind the area to be welded and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com