H-steel pre-assembling mechanism

A pre-assembled, H-shaped steel technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, long assembly time, trouble, etc., and achieve high efficiency of flipping and centering, production efficiency High efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

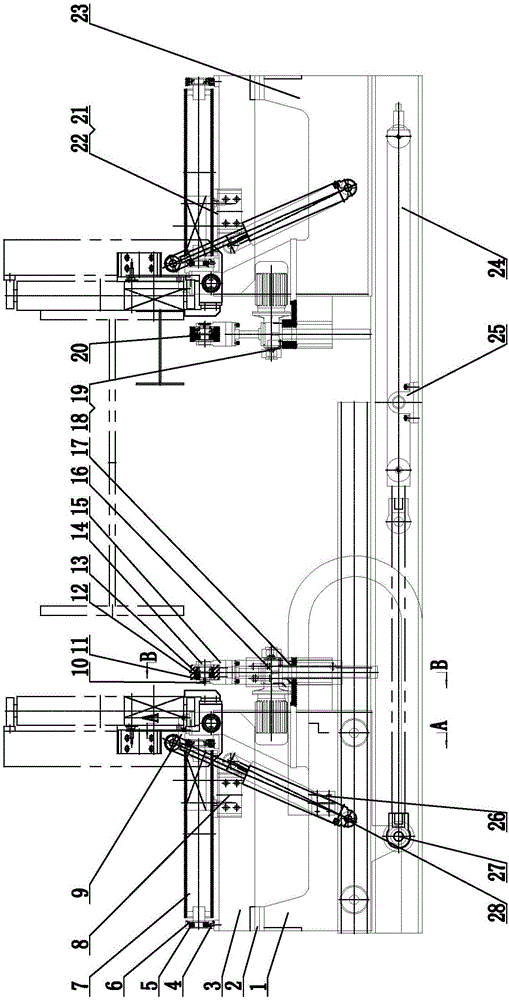

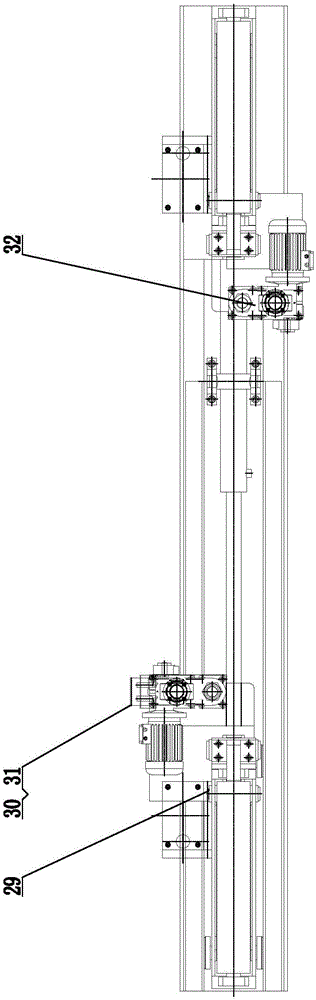

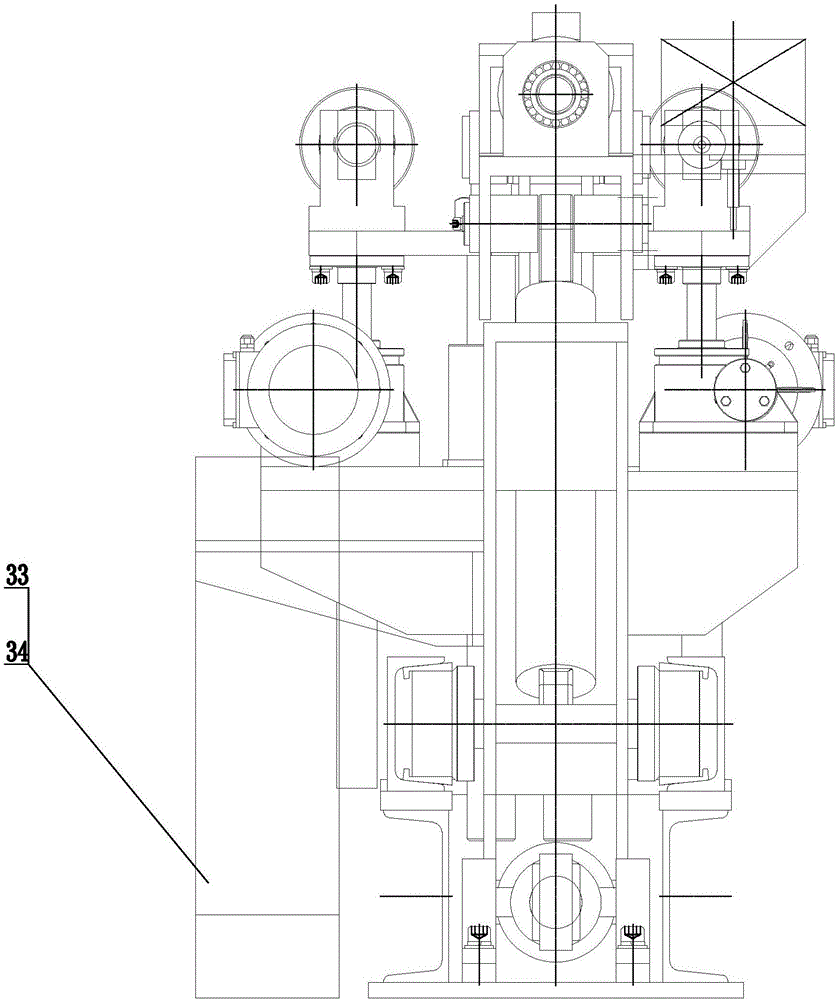

[0022] Figure 1 to Figure 5 As shown, the H-shaped steel pre-assembly mechanism of the present invention includes a left oil cylinder mounting frame 1 and a right oil cylinder mounting frame 23 installed on the base 44, and flipping parts are respectively installed on the left oil cylinder mounting frame 1 and the right oil cylinder mounting frame 23; The overturning part comprises a drum mounting frame 3, and one end of the drum mounting frame 3 is rotationally connected with the left oil cylinder mounting frame 1 or the right oil cylinder mounting frame 23 through a copper sleeve 35 and a turning shaft 36, and a cover plate 37 is set at the shaft end of the turning shaft 36; The first bearing 5 and the first hole retaining ring 6 are used to install the overturning cylinder 7 on the roller mounting frame 3, the first bearing 5 is arranged in the bearing seat 4, and the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com