Engraving machine with high precision and high stability

A high-stability, high-gloss machine technology, applied in the direction of manufacturing tools, grinding racks, grinding machine parts, etc., can solve the problems of large displacement errors, resonance of the cutter head, and unreachable surface accuracy, etc., to achieve improved Surface accuracy, small driving vibration, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings:

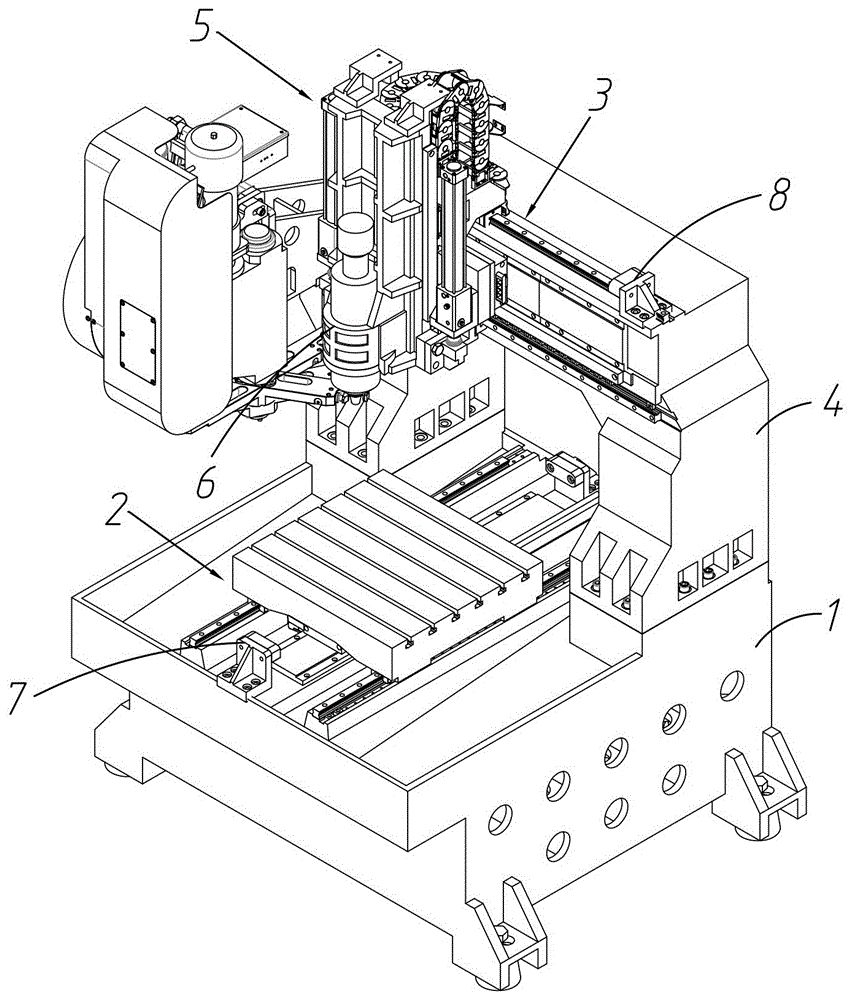

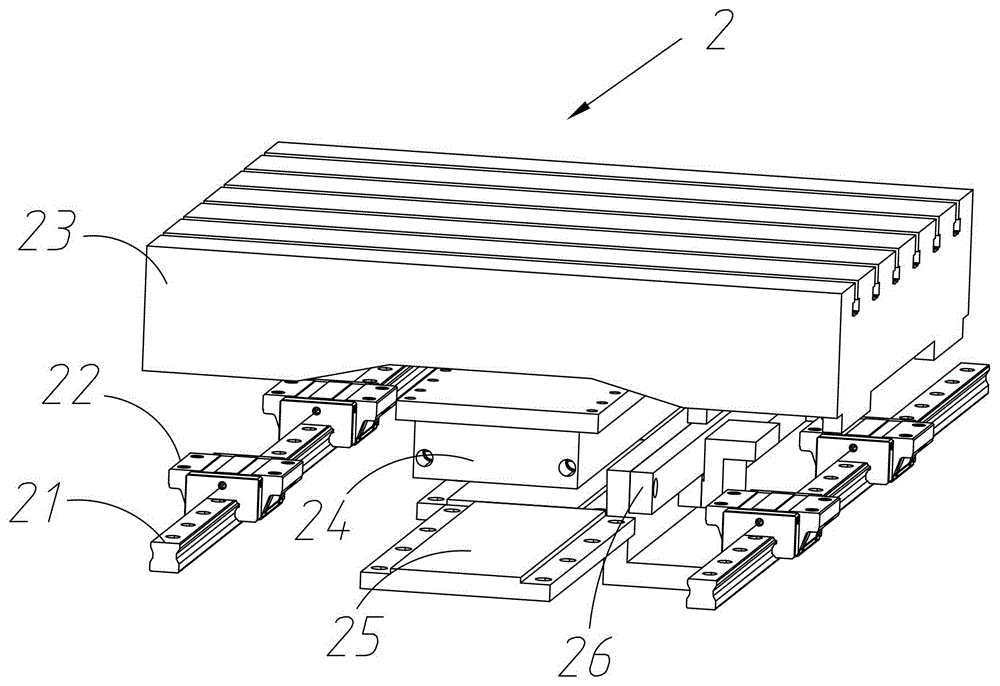

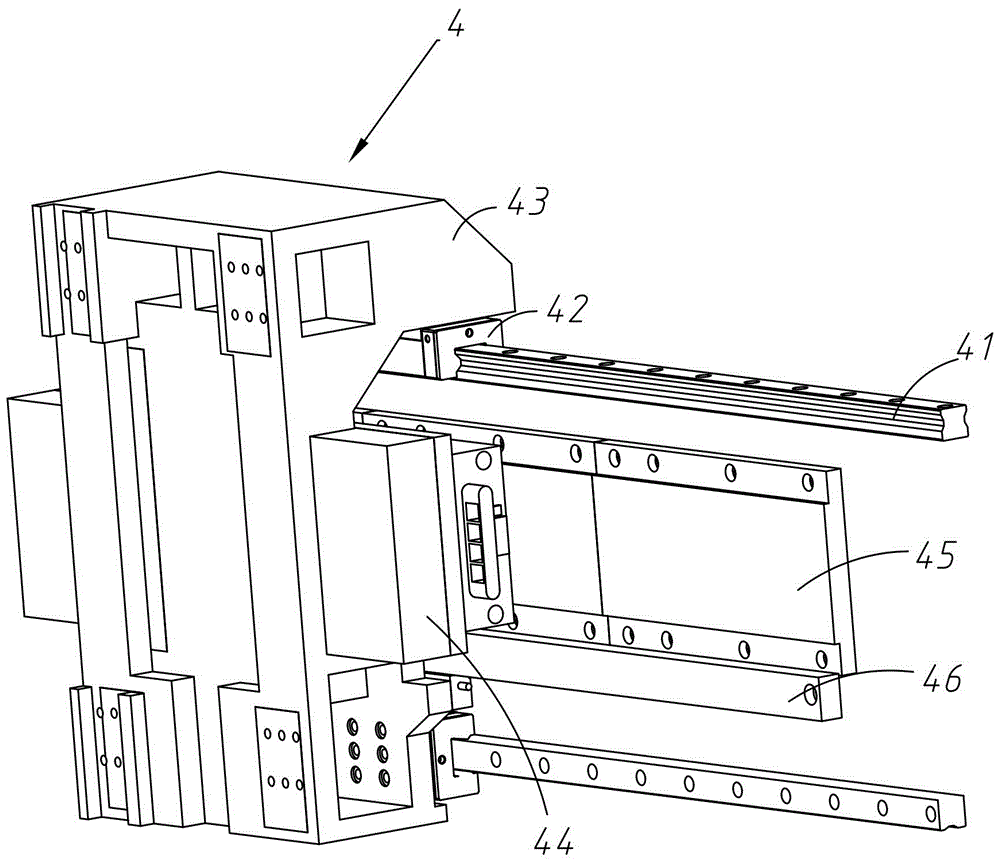

[0022] Such as Figure 1 to Figure 6 Shown is a high-precision and high-stability highlight machine, including a base 1, a Y-axis movement module 2, a gantry 3, an X-axis movement module 4, a Z-axis movement module 5, and a tool head spindle 6. , The Y-axis moving module 2 is installed on the base 1, and the Y-axis moving module 2 includes a Y-direction linear guide 21 installed on the base 1, and a Y-direction sliding guide installed on the Y-direction linear guide 21. Block 22, worktable 23 mounted on the Y-direction slider 22, Y-direction linear motor 24 mounted on the center of gravity of the bottom surface of the worktable 23, Y-direction mounted on the base 1 and matched with the Y-direction linear motor 24 A motor magnetic plate 25 and a Y-direction grating ruler 26 for accurately controlling the moving distance of the worktable, the worktable 23 being driven by the Y-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com