A metal wire drawing machine

A wire drawing machine and metal technology, which is applied to metal processing equipment, grinding machine parts, grinding workpiece supports, etc., can solve the problems of accelerated spindle bearing wear, cumbersome maintenance, and reduced processing accuracy of wire drawing machines. Longevity, the effect of reducing maintenance difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

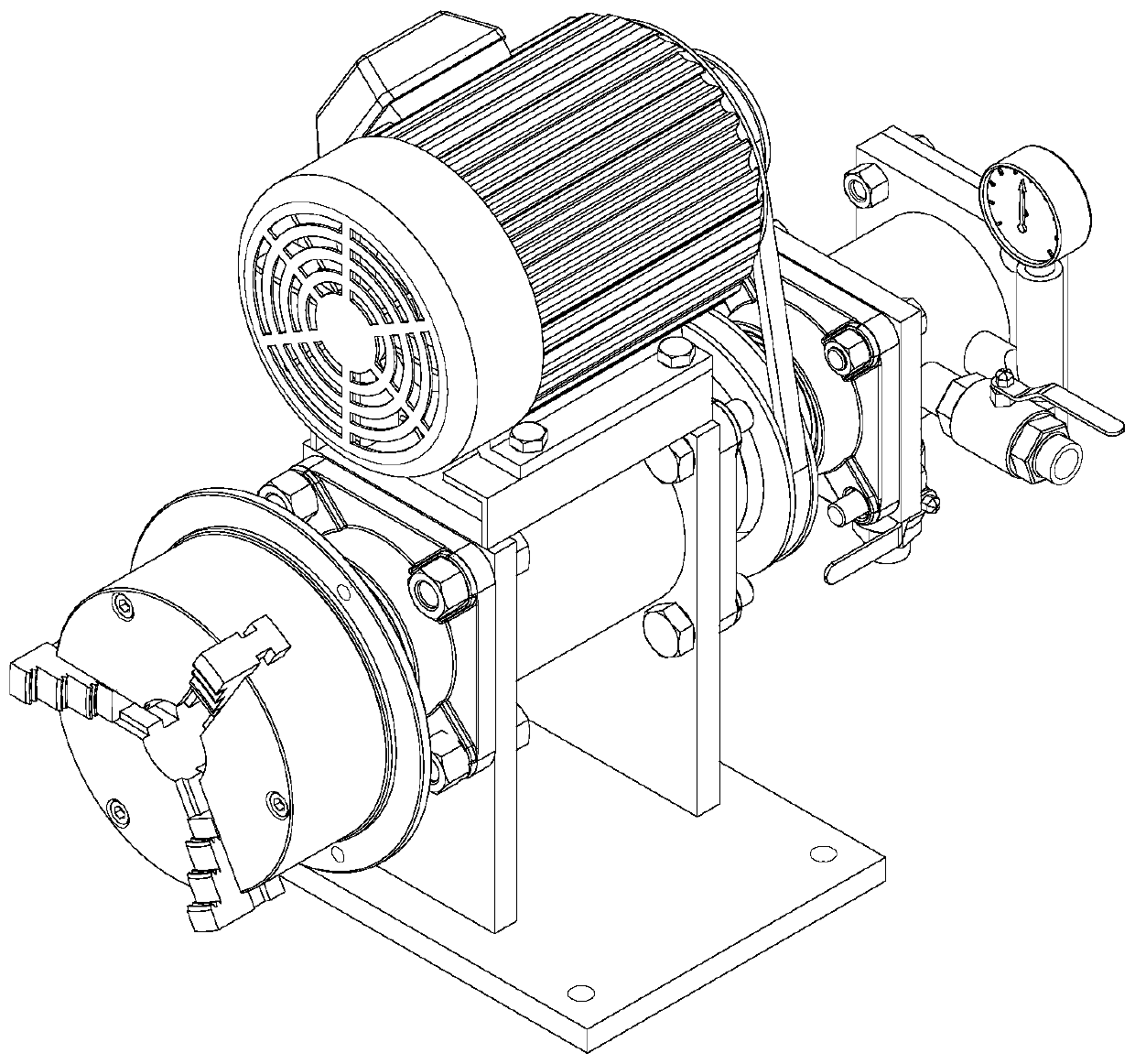

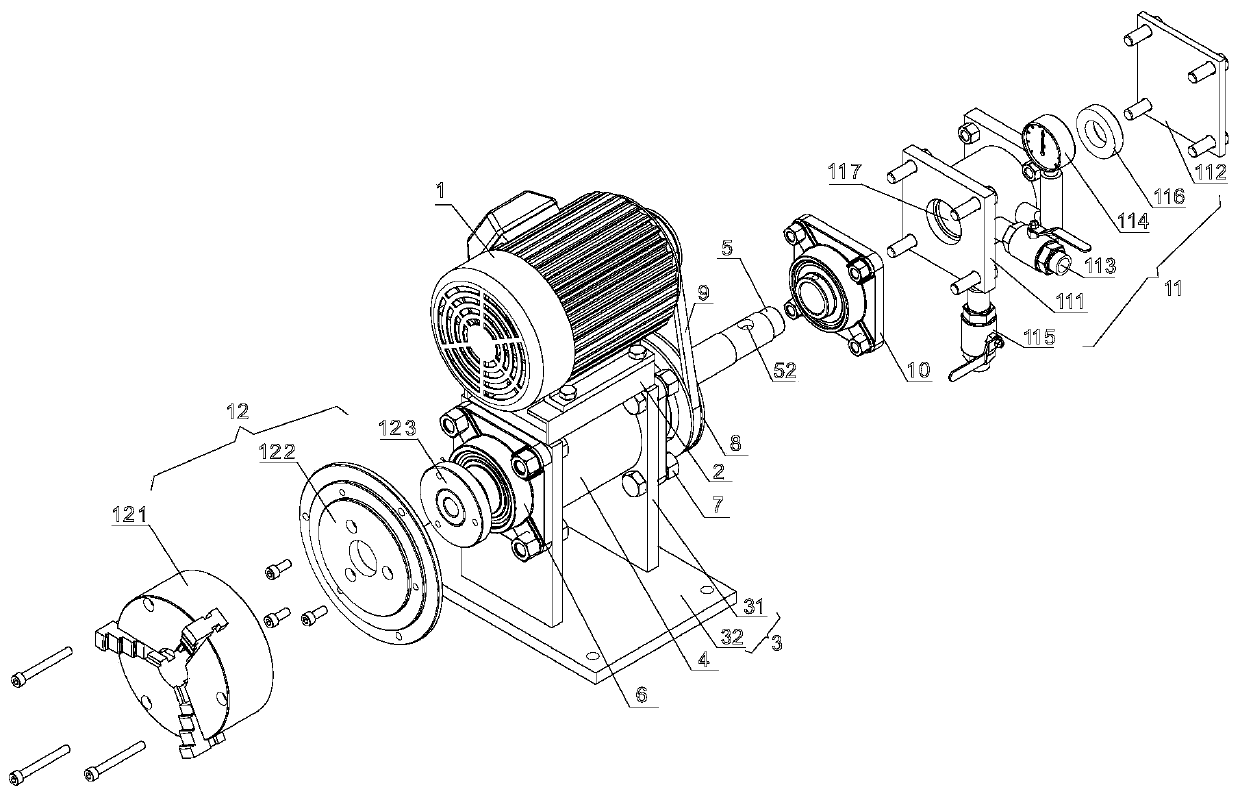

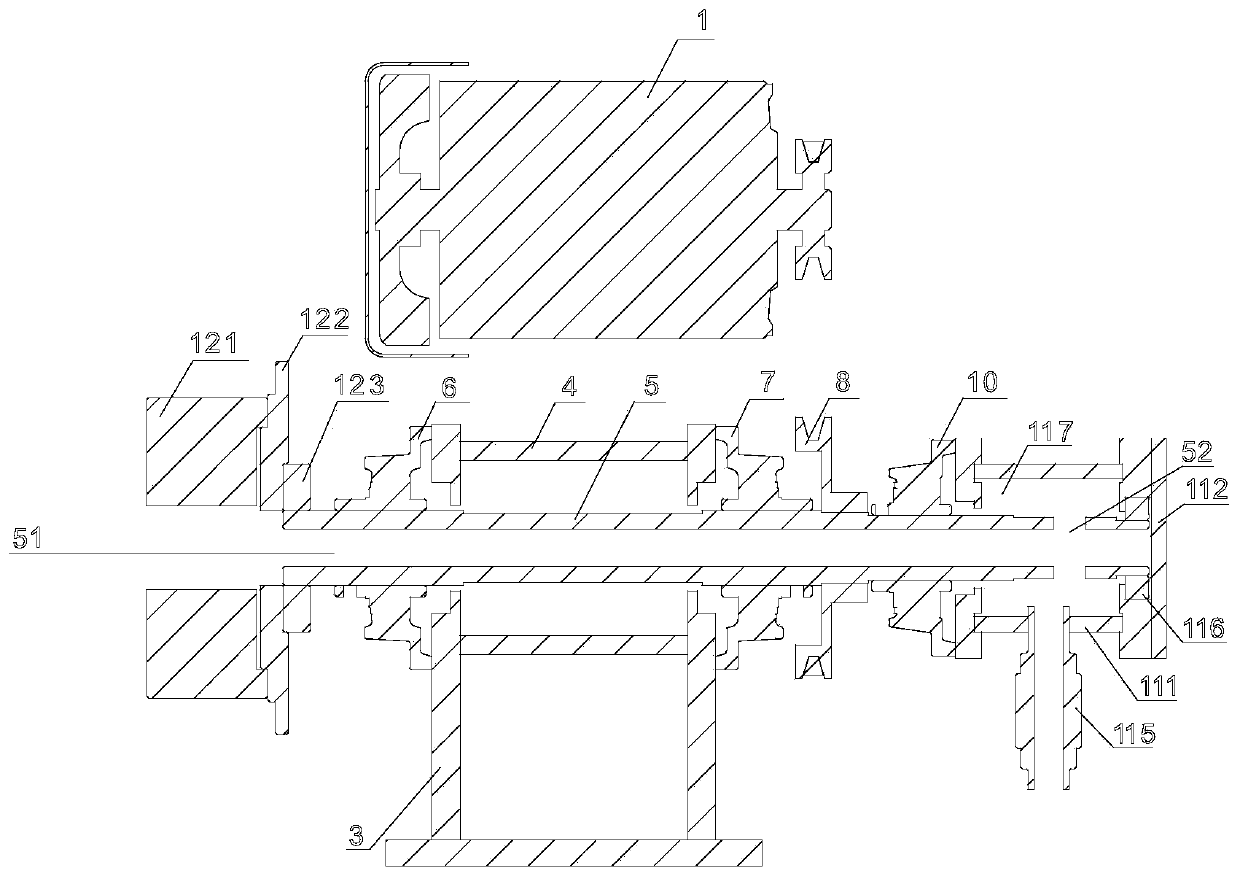

[0028] like figure 1 , the metal wire drawing machine in this embodiment includes a motor 1, a motor base 2, a main shaft base 3, a main shaft cavity housing 4, a main shaft 5, a left main shaft bearing 6, a right main shaft bearing 7, a main shaft pulley 8, and a belt 9, Vacuum chamber bearing 10, vacuum chamber assembly 11, clamping assembly 12.

[0029] The spindle base 3 includes two vertical plates 31 and a horizontal bottom plate 32 , and the two vertical plates 31 are arranged above the horizontal bottom plate 32 and fixedly connected with the horizontal bottom plate 32 . The main shaft cavity housing 4 is arranged between two vertical plates 31 and is fixedly connected with the vertical plates 31 . The main shaft cavity housing 4 is cylindrical, and the main shaft cavity is formed inside. The shaft center of the main shaft 5 is provided with a main shaft longitudinal hole 51, and the right end of the main shaft 5 is radially provided with a main shaft transverse hole...

Embodiment 2

[0036] The structure of the metal wire drawing machine in this embodiment is substantially the same as that in Embodiment 1, except that the clamping assembly 12' includes a vacuum suction cup 121', a suction cup flange 122' and a main shaft flange 123'. The main shaft flange 123' is sleeved on the main shaft 5' and is located at the left end of the left main shaft bearing 6'. The suction cup flange 122' is set on the main shaft 5', is set on the main shaft flange 123' and is fixedly connected with it. The vacuum suction cup 122' is sleeved on the main shaft 5' and fixedly connected with the suction cup flange 121'.

[0037] After the vacuum valve 113' is connected to the vacuum pump (not shown), close the sewage valve 115', open the vacuum valve 113', and form a vacuum suction force outside the vacuum chuck 122', which can absorb the workpiece and carry out wire drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com