Automatic-leveled bearing worktable for ship

An automatic leveling and workbench technology, which is applied in the direction of workbenches, ship accessories, manufacturing tools, etc., can solve the problem that the leveling device cannot be adjusted in real time, and achieve the effect of improving operation stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

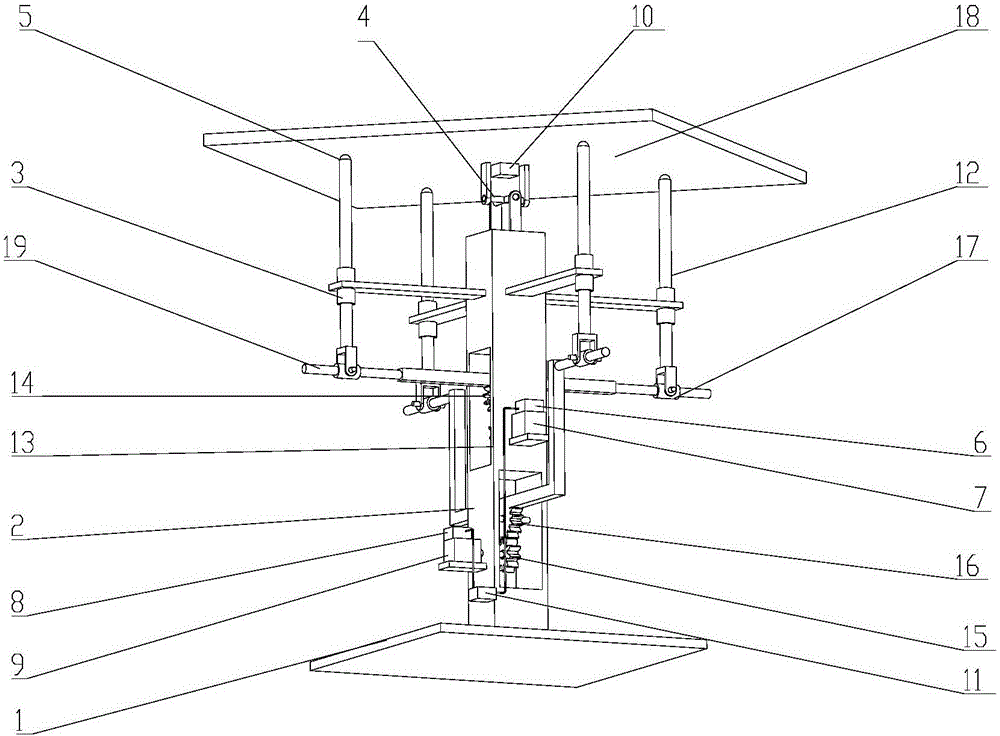

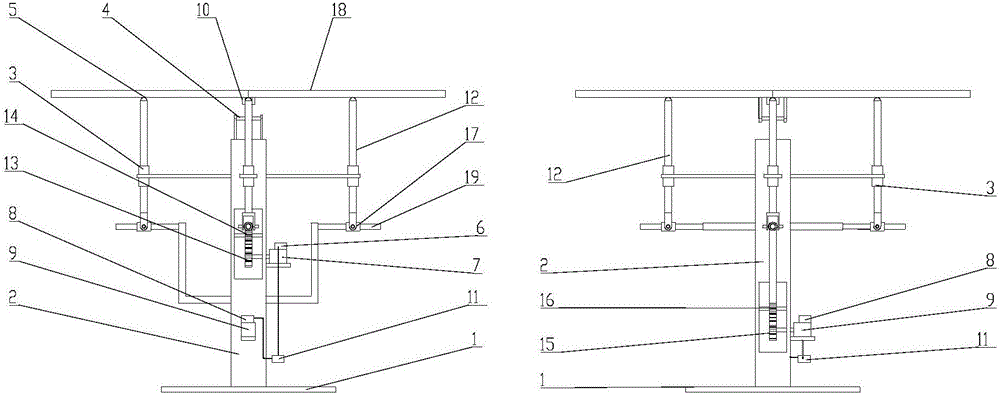

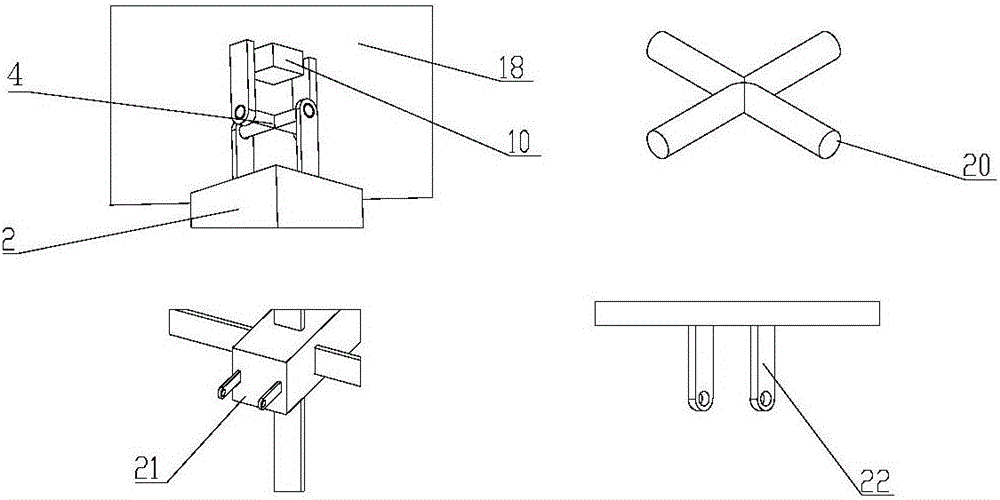

[0028] Such as figure 1 , figure 2 A self-leveling load-bearing workbench is shown, including a load-bearing workbench surface, characterized in that: the load-bearing workbench surface 18 is a square flat plate, and a universal joint 4 is installed at the center of its bottom surface. A two-dimensional inclination sensor 10 is installed in the middle space, and the two coordinate axes of the two-dimensional inclination sensor 10 coincide with the two diagonals of the bearing workbench panel 18. The lower end of the universal joint 4 is installed on the base support 2, and the base 1. The upper part is rigidly connected with the base bracket 2, and the base bracket 2 is equipped with two sets of gear transmission devices, including motor drive gears 13, 15 and matching leveling gears 14, 16, such as Figure 4 As shown, the two mesh with each other. Motor drive gear 13,15 is connected on the output shaft of servomotor 7,9, and servomotor 7,9 is fixed on base bracket 2, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com