Six-axis robot

A six-axis robot and reducer technology, applied in the field of manipulators, can solve the problems of incapability of mass production and widespread promotion, single function of manipulators, limited moving range, etc., to avoid joint motion jitter, low maintenance costs, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

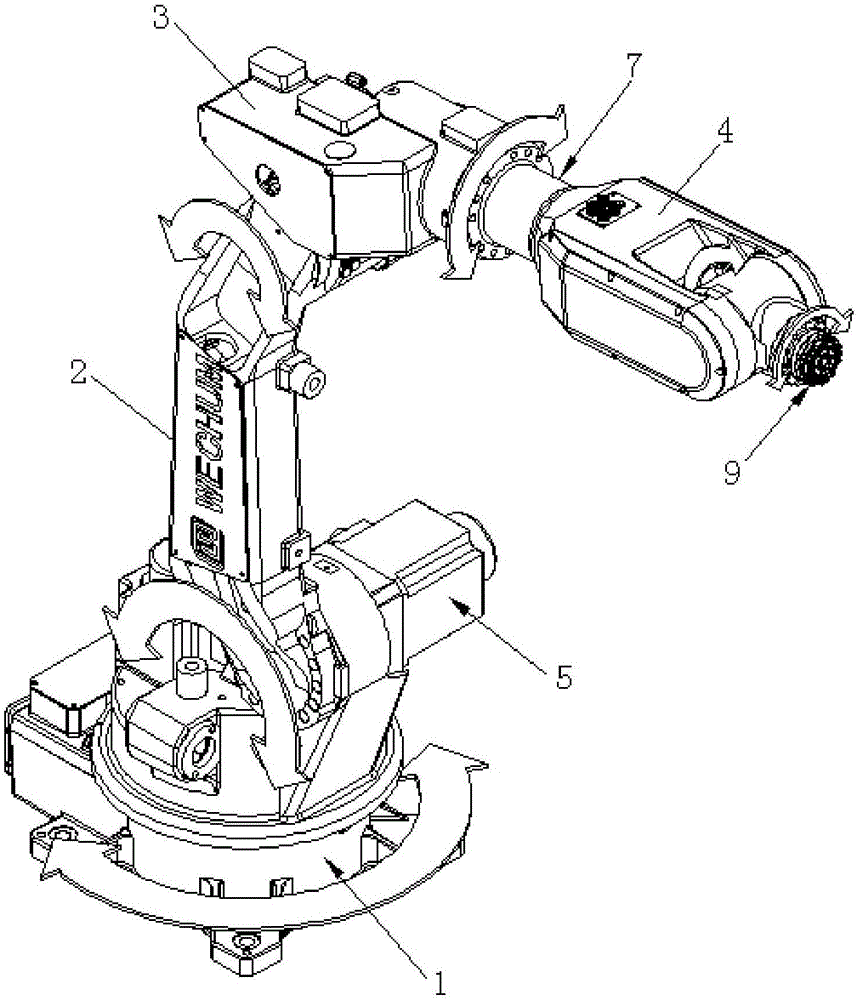

[0065] See attached Figure 1~4 As shown in FIG. 1 , the three-dimensional structure schematic diagram, the front view structural schematic diagram and the side view structural schematic diagram of the first embodiment of the six-axis robot in the present invention are respectively shown. The six-axis robot includes a rotating base 1, a swing arm 2, a receiving base 3, a swing head 4, a first swing drive mechanism 5, a second swing drive mechanism 6, a rotation drive mechanism 7, a third swing drive mechanism 8, and An end effector 9 for receiving the grabbing assembly and driving the grabbing assembly to rotate (the grabbing assembly can use vacuum chucks, pneumatic grippers, or electromagnets), wherein the swing arm 2 is vertically arranged on the rotating on the base 1, and can rotate horizontally under the drive of the rotating base 1; the first swing driving mechanism 5 is also arranged on the rotating base 1, and the first swing driving mechanism 5 can also drive the Th...

Embodiment 2

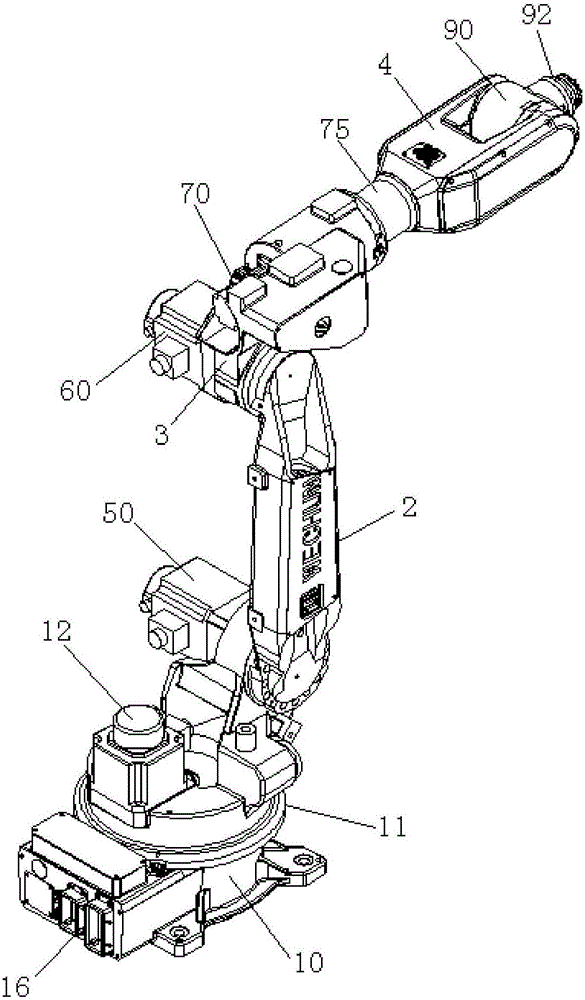

[0077] See attached Figures 12 to 15 As shown, the three-dimensional structure schematic diagram, the front view structural schematic diagram and the side view structural schematic diagram of the second embodiment of the six-axis robot of the present invention are respectively shown.

[0078] The difference between the six-axis robot shown in Embodiment 2 and the six-axis robot shown in Embodiment 1 mainly lies in: the appearance shape is different, and the assembly method between the rotary drive mechanism and the swing head is different (refer to the attached Figure 16 shown); the structure of the remaining parts / mechanisms in the six-axis robot shown in Embodiment 2, and the connection relationship and action principle between the remaining parts / mechanisms are all the same as in Embodiment 1.

Embodiment 3

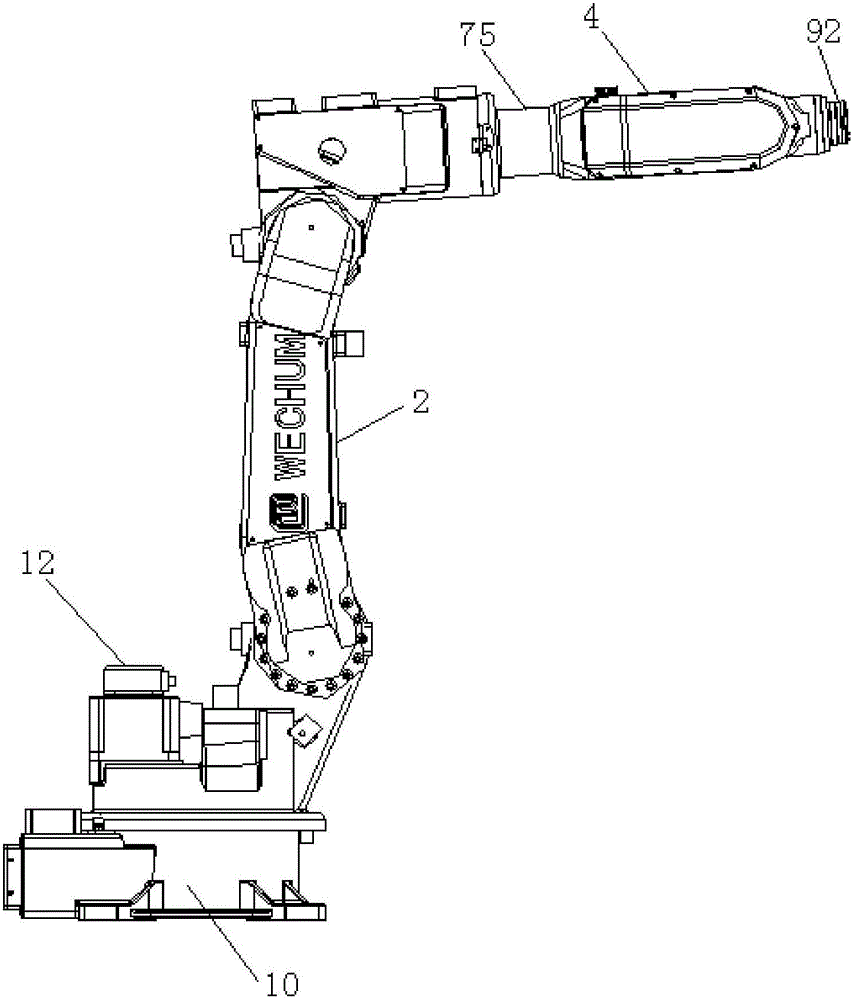

[0080] See attached Figures 17-20 As shown, the three-dimensional structure schematic diagram, the front view structural schematic diagram and the side view structural schematic diagram of the third embodiment of the six-axis robot of the present invention are respectively shown.

[0081] The difference between the six-axis robot shown in Embodiment 3 and the six-axis robot shown in Embodiment 1 mainly lies in the difference in appearance and shape, and the difference in the assembly method between the second swing driving mechanism and the receiving seat (refer to the attached Figure 21 shown), and the assembly method between the rotary drive mechanism and the swing head is different (refer to the attached Figure 22 shown); the structure of the remaining parts / mechanisms in the six-axis robot shown in Embodiment 3, and the connection relationship and action principle between the remaining parts / mechanisms are all the same as in Embodiment 1.

[0082] To sum up, compared w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com