A linear tear, high barrier polyamide film

A polyamide film, high barrier technology, applied in the field of flexible packaging film, biaxially stretched film, to achieve the effects of excellent linear tearing performance, excellent barrier performance, and convenient user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

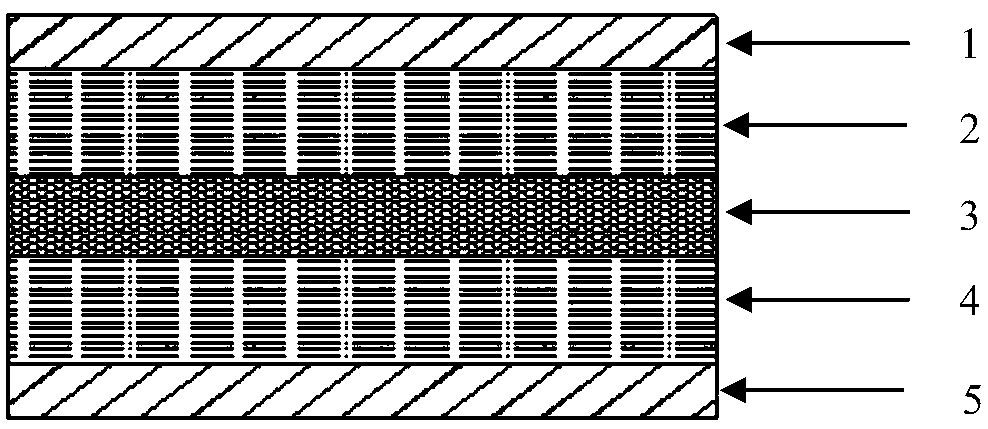

[0032] A kind of linear tearing of the present invention, the preparation method of high barrier polyamide film comprises the following steps:

[0033] In the first step, each layer of material corresponding to the first surface layer, the first tear layer, the barrier layer, the second tear layer and the second surface layer is heated and melted through an extruder; extruded through a five-layer die to make the melt The body is cooled on chilled rolls to form cast flakes. Five extruders or three extruders can be used for co-extrusion, preferably three extruders for co-extrusion: the first surface layer and the second surface layer share one extruder, and the first tear layer Share an extruder with the second tear layer and use an extruder for the barrier layer.

[0034] In the second step, the cast sheet is preheated in a water bath of 40-60°C, and then subjected to a humidity-conditioning treatment in a water bath of 60-75°C, and the surface moisture of the cast sheet is dr...

Embodiment 1

[0045] A linear tearing, high barrier polyamide film, wherein the composition of the first surface layer is 94.8% PA6, 5% aromatic polyamide, 0.1% silicon dioxide, 0.1% erucamide; the composition of the first tearing layer is 78 % PA6, 20% aromatic polyamide, 1% toughening agent, 1% compatibilizer; barrier layer composition is 100% EVOH; second tear layer composition is 78% PA6, 20% aromatic polyamide, 1% Toughening agent, 1% compatibilizer; second surface layer components are 94.8% PA6, 5% aromatic polyamide, 0.1% silicon dioxide, 0.1% erucamide.

[0046] The thickness ratio of each layer of the film in this embodiment is 1 / 4 / 5 / 4 / 1, and the total thickness is 15 μm.

Embodiment 2

[0048] A linear tearing, high barrier polyamide film, wherein the composition of the first surface layer is 88% PA6, 10% aromatic polyamide, 1.0% silicon dioxide, 1.0% erucamide; the composition of the first tearing layer is 50% % PA6, 40% aromatic polyamide, 5% toughening agent, 5% compatibilizer; barrier layer composition is 100% EVOH; second tear layer composition is 50% PA6, 40% aromatic polyamide, 5% Toughening agent, 5% compatibilizer; second surface layer composition is 88% PA6, 10% aromatic polyamide, 1.0% silicon dioxide, 1.0% erucamide.

[0049] The thickness ratio of each layer of the film in this embodiment is 2 / 3 / 5 / 3 / 2, and the total thickness is 15 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com